Hanging basket rope unreeling and reeling mechanism

A technology for arranging ropes and hanging baskets, applied in the direction of the spring mechanism, hoisting device, etc., can solve the problems of wire rope arrangement, wire rope winding or concentration, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described below in conjunction with specific drawings and embodiments.

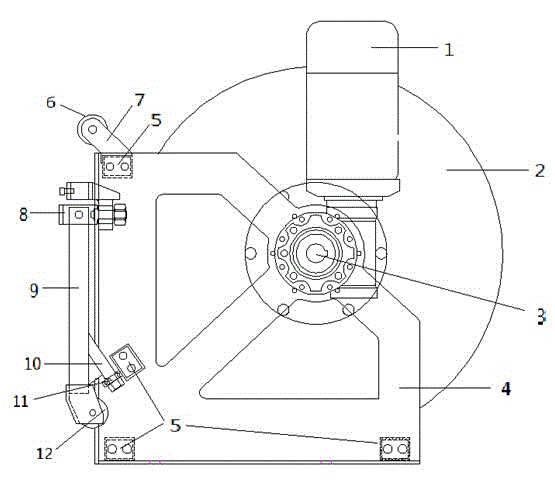

[0012] Such as figure 1 Shown: the present invention mainly consists of motor 1, rope receiving reel 2, rotating shaft 3, winch support 4, cross brace 5, guide wheel 6, guide wheel frame 7, swing arm hinge 8, swing arm 9, diagonal strut 10, The swing arm pulley 11 and the guide pulley 12 are composed; the motor 1 is fixed on one side of the winch bracket 4 by bolts; the rope receiving reel 2 is installed on the winch bracket 4 through the rotating shaft 3, and one end of the rotating shaft 3 is inserted into the motor 1 In the pin hole, it is fixed by a flat key; the guide wheel 6 is installed on the guide wheel frame 7 through bolts, and the guide wheel frame 7 is fixed on the cross brace 5; the swing arm 9 is installed on the winch bracket 4 through the swing arm hinge 8 Above, the rope guide pulley 12 is installed on the lower end of the swing arm 9;

[00...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap