Preparation method of macroporous adsorption resin

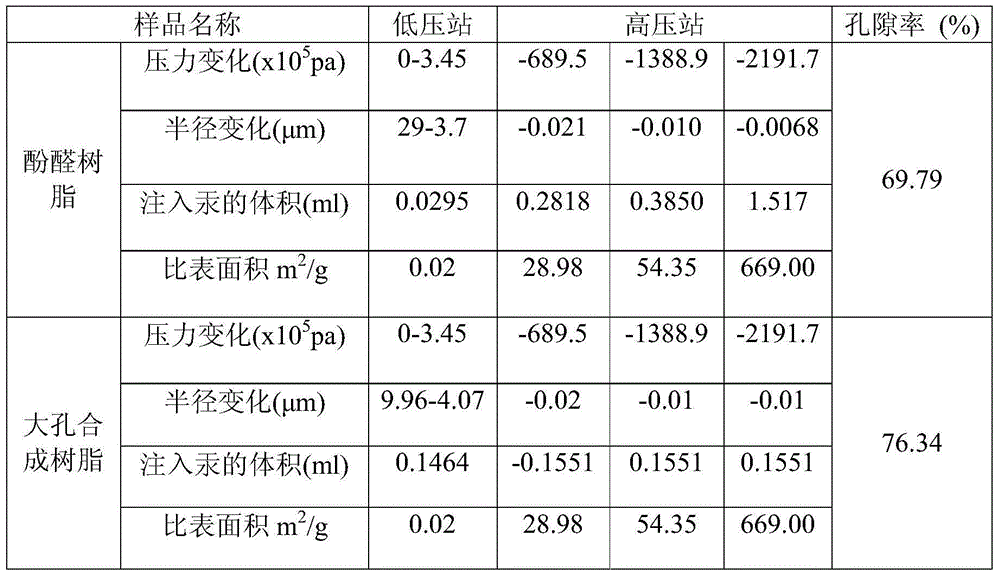

A pore adsorption and resin technology, applied in the field of macroporous resin preparation, can solve the problems of secondary pollution, large environmental pollution, poor separation effect, etc., and achieve the effect of high porosity and improved separation effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0021] Example 1

[0022] Take 40g of ethylene-vinyl acetate, 150g of methacrylonitrile and 450g of styrene with a weight percentage of 53% in a beaker, add 640g toluene, 320g xylene, 6.4g benzoyl peroxide and 6.4g azo Diisobutyronitrile is mixed until it is homogeneous to obtain an oil phase.

[0023] Take 1000 g of deionized water, add 10 g of polyvinyl alcohol, 10 g of gelatin, and 100 g of sodium chloride under stirring, and stir to dissolve, and then add 1000 g of deionized water and mix well to prepare the water phase.

[0024] Take 900g of the water phase and place it in the flask, take 300g of the oil phase and add it to the water phase, turn on the stirrer, adjust the speed to 30 rpm, and start to slowly increase the temperature when the oil droplet size is 0.3mm, and the temperature rise rate is 2℃ / 10 points. When it reaches 66°C, react at a constant temperature for 2 hours. Then increase the temperature to 68°C at the same rate and react for 4 hours; then increase the ...

Example Embodiment

[0029] Example 2

[0030] Take 80 g of ethylene-vinyl acetate, 350 g of methacrylonitrile and 800 g of styrene with a weight percentage of 55% in a beaker, add 1845 g toluene, 1845 g xylene, 36.9 g benzoyl peroxide and 36.9 g azo Diisobutyronitrile is mixed until it is homogeneous to obtain an oil phase.

[0031] Take 1000 g of deionized water, add 28 g of polyvinyl alcohol, 20 g of gelatin, and 200 g of sodium chloride while stirring, and stir to dissolve, then add 1000 g of deionized water and mix well to prepare the water phase.

[0032] Take 1500g of the water phase and place it in the flask, take 300g of the oil phase and add it to the water phase, turn on the stirrer, adjust the speed to 60 rpm, and start to slowly increase the temperature when the oil droplet size is 1.0mm, and the temperature rise rate is 2℃ / 10 points. When it reaches 68°C, react at a constant temperature for 2 hours. Then increase the temperature to 71°C at the same rate and react for 6 hours; then incre...

Example Embodiment

[0037] Example 3

[0038] Take 60g of ethylene-vinyl acetate, 250g of methacrylonitrile and 620g of 54% styrene by weight and place them in a beaker. Add 1162.5g of toluene, 930g of xylene, 14g of benzoyl peroxide and 14g of azobis Isobutyronitrile is mixed until it is homogeneous to obtain an oil phase.

[0039] Take 1000 g of deionized water, add 20 g of polyvinyl alcohol, 15 g of gelatin, and 150 g of sodium chloride under stirring, and stir to dissolve, and then add 1000 g of deionized water and mix well to prepare the water phase.

[0040] Take 1200g of water phase and place it in the flask, take 300g of oil phase and add it to the water phase, turn on the stirrer, adjust the speed to 45 rpm, and start to slowly increase the temperature when the oil droplet size is 0.6mm, and the temperature rise rate is 2℃ / 10 points. When it reaches 67°C, react at a constant temperature for 2 hours. Then increase the temperature to 69°C at the same speed and react for 5 hours; then increase...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap