Method and device for dumping garbage with double transfer buckets of electric cleaning vehicle

A transfer bucket and cleaning vehicle technology, which is applied in cleaning methods, road surface cleaning, construction, etc., can solve the problems of short cleaning operation time, low use efficiency, and high power of fan dust collection devices, so as to avoid continuous operation and reduce costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The preferred embodiments of the present invention are described in detail below with reference to the accompanying drawings.

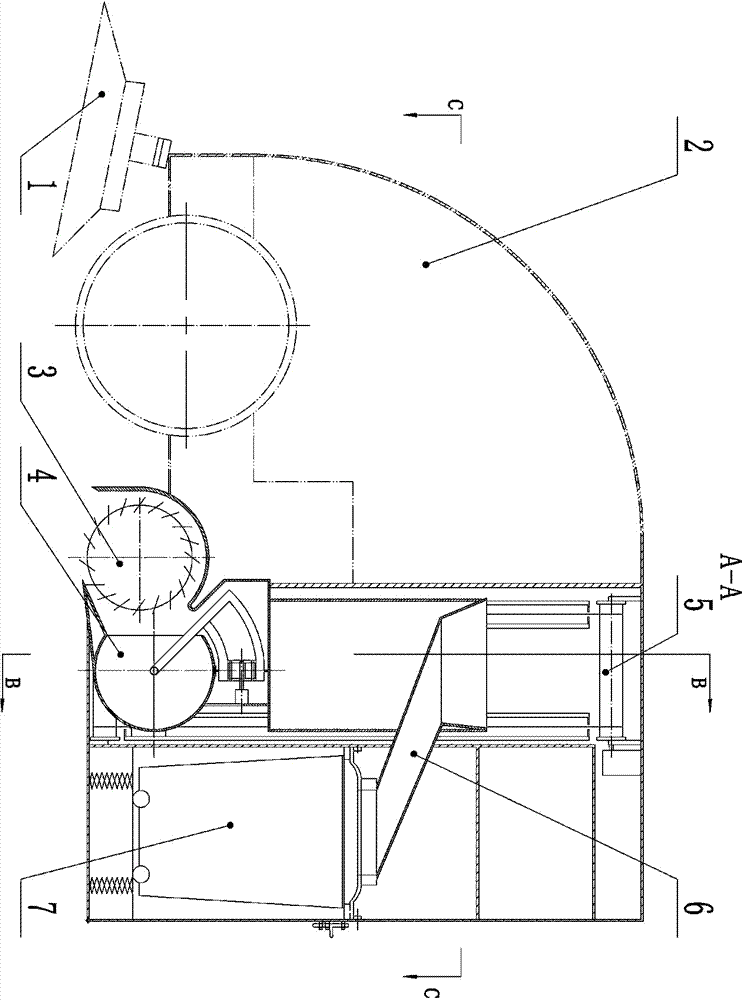

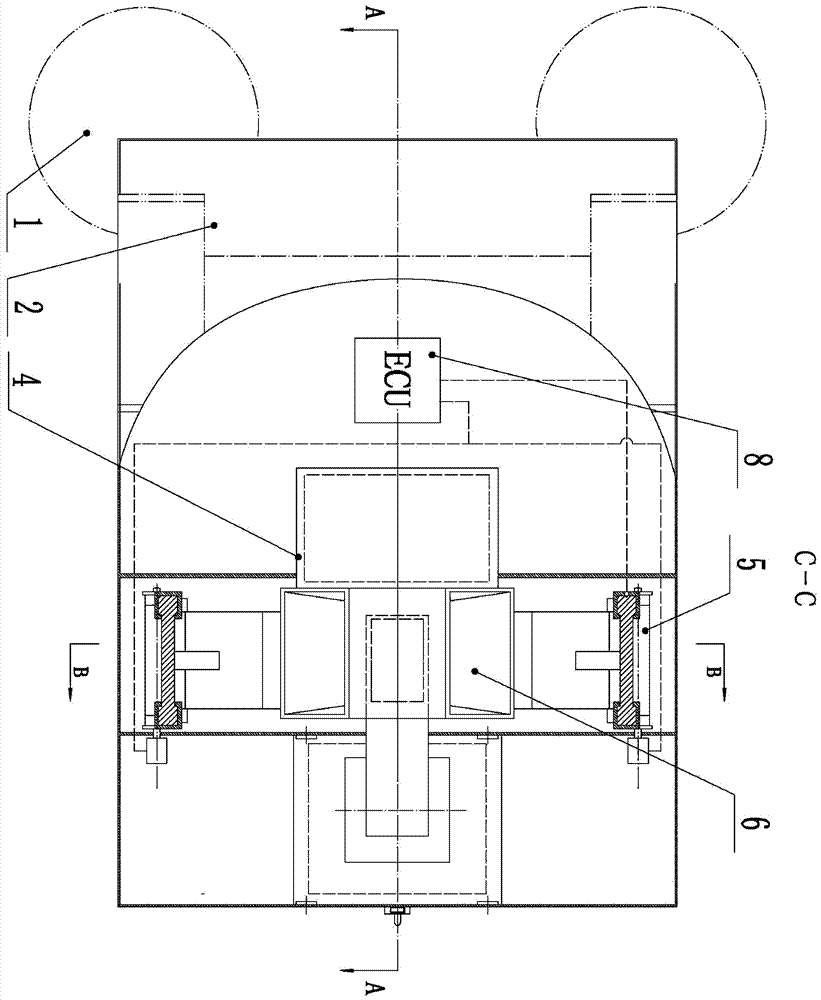

[0021] figure 1 Show the specific embodiment of the present invention: electric sweeper body 2 bottoms are provided with disc brush device 1 and roller brush device 3, are provided with garbage transfer device 4 on the bottom plate behind roller brush device 3; Transfer device 4 left and right sides It is a lifting device 5 with a transfer bucket, and the side dump slideway 6 is directly above the transfer device 4; a standard garbage can 7 is provided in the rear compartment of the electric sweeper, and the entire double-transfer bucket garbage dump device uses electricity for operation. Control system 8 controls.

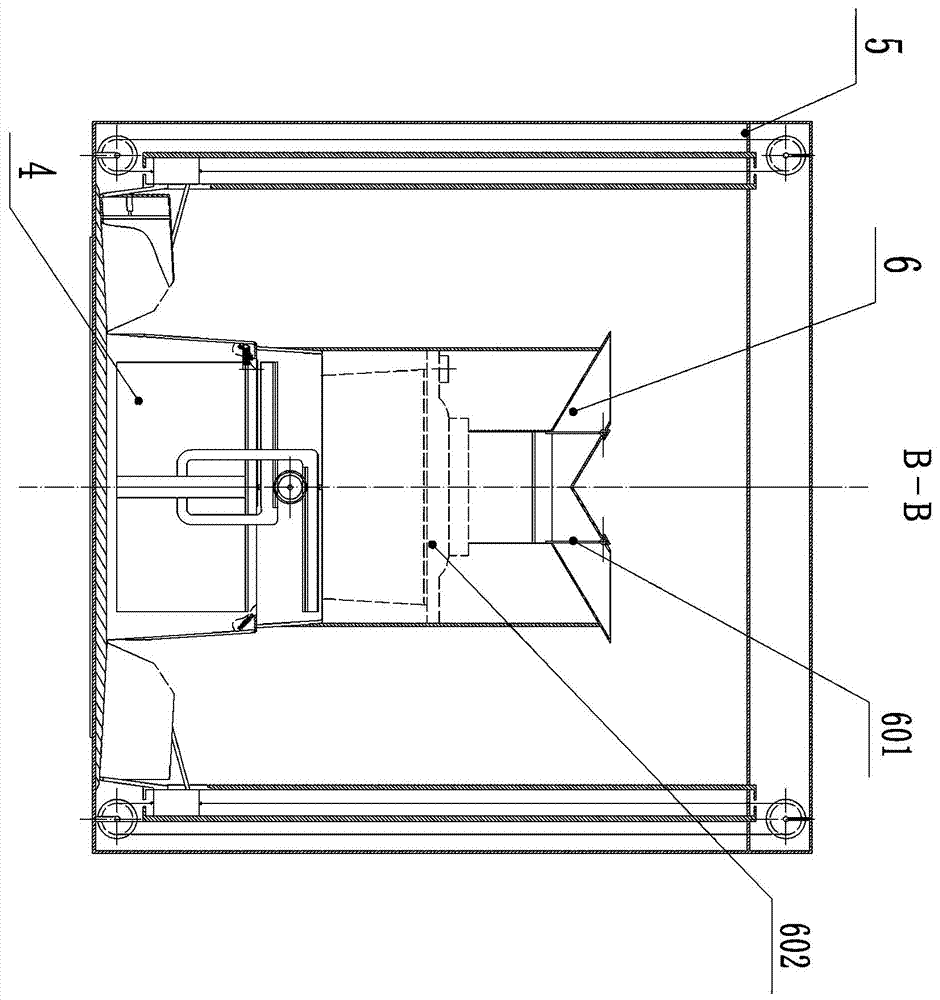

[0022] figure 1 Show the described lateral dumping chute 6 . The lateral dumping slideway 6 is a "y"-shaped two-stage rectangular cross-section structure. The upper slideway is a structure that divides sideways from the left an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com