A thermal ticket printer to prevent local overheating

A local overheating and printer technology, applied in printing and other directions, can solve the problems of reducing the speed of ticket issuance, overheating, and the inability of heating elements to dissipate heat in time, so as to avoid printing interruptions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] In order to enable those skilled in the art to better understand the technical solution of the present invention, and to make the above-mentioned purpose, features and advantages of the present invention more obvious and understandable, the present invention will be further described in detail below in conjunction with the embodiments and accompanying drawings .

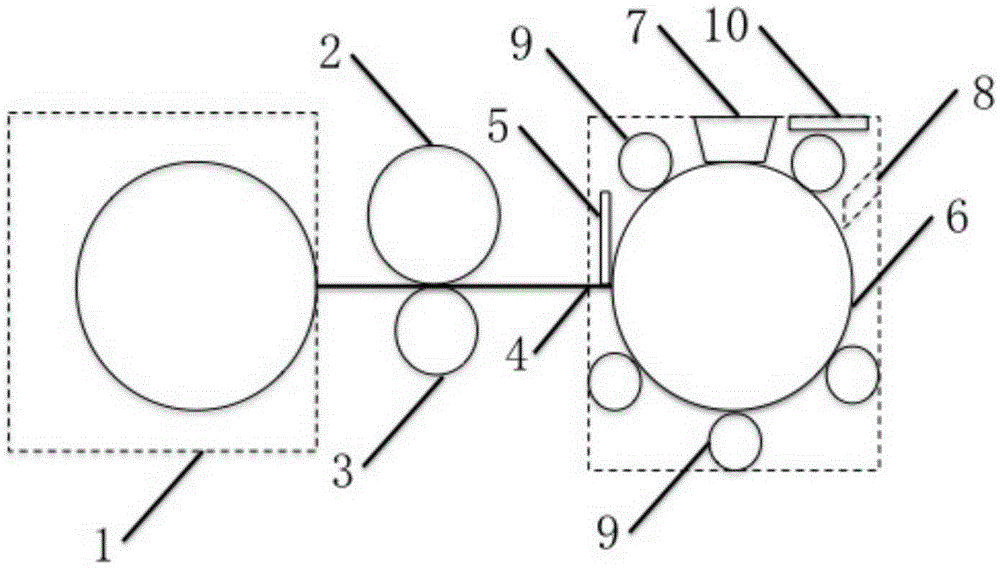

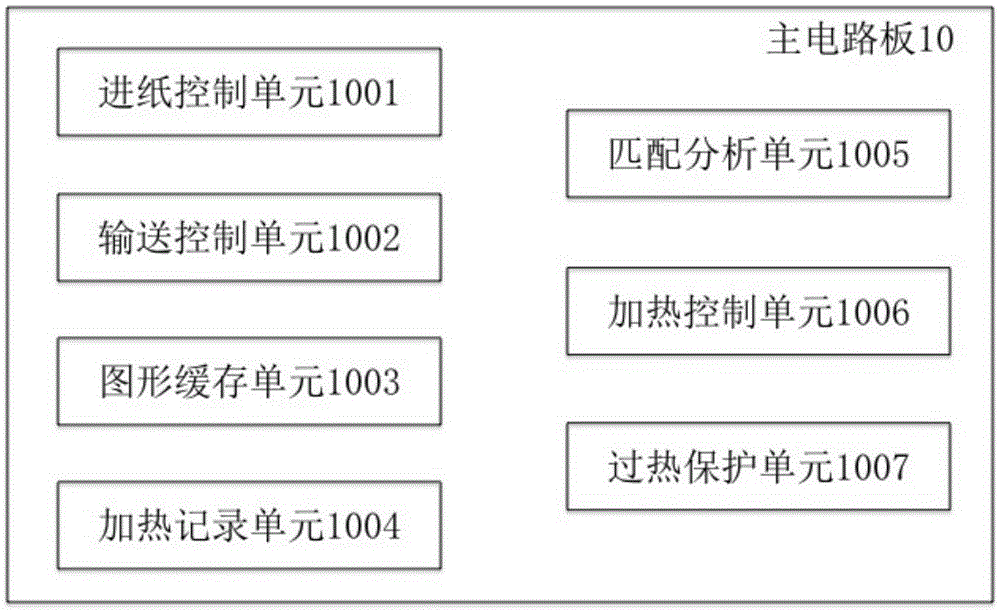

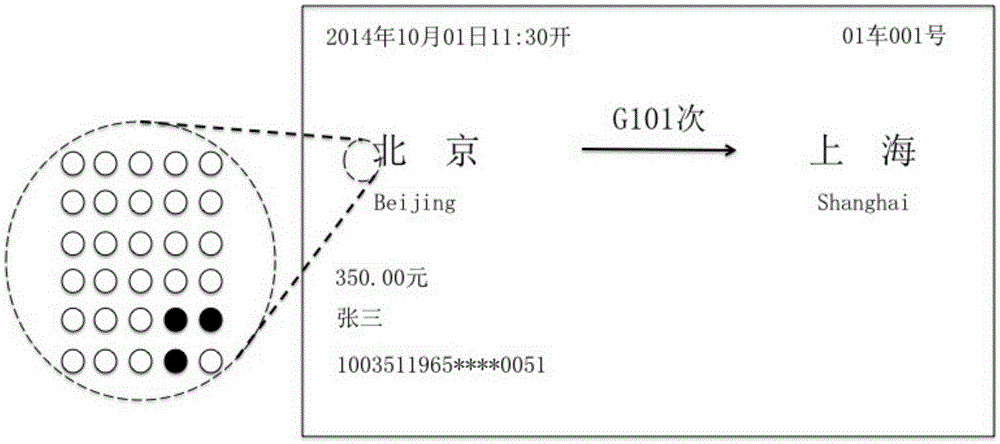

[0046] The process of thermal ticket printing is to use the print head with row-arranged heating elements to heat specific points on the ticket substrate made of thermal paper according to the bitmap of the ticket template until the color develops. Since the print head is composed of a row of heating elements arranged one by one, a row of dots can be printed in one printing cycle. The paper-feeding mechanism driven by the stepping motor is responsible for moving the ticket substrate, so as to cooperate with the printing head to complete the printing of the ticket face line by line. The printing of the ticket ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com