Universal supporting combined frame supporting unit and universal supporting combined frame

A technology of support unit and combined frame, which is applied in the direction of house structure support, house structure support, construction, etc., can solve the problems of waste of labor, inconvenient handling, inflexibility, etc., and achieves reduction of production cost, simple and reasonable design, and convenient height adjustment. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0058] A support unit for a universal support combination frame:

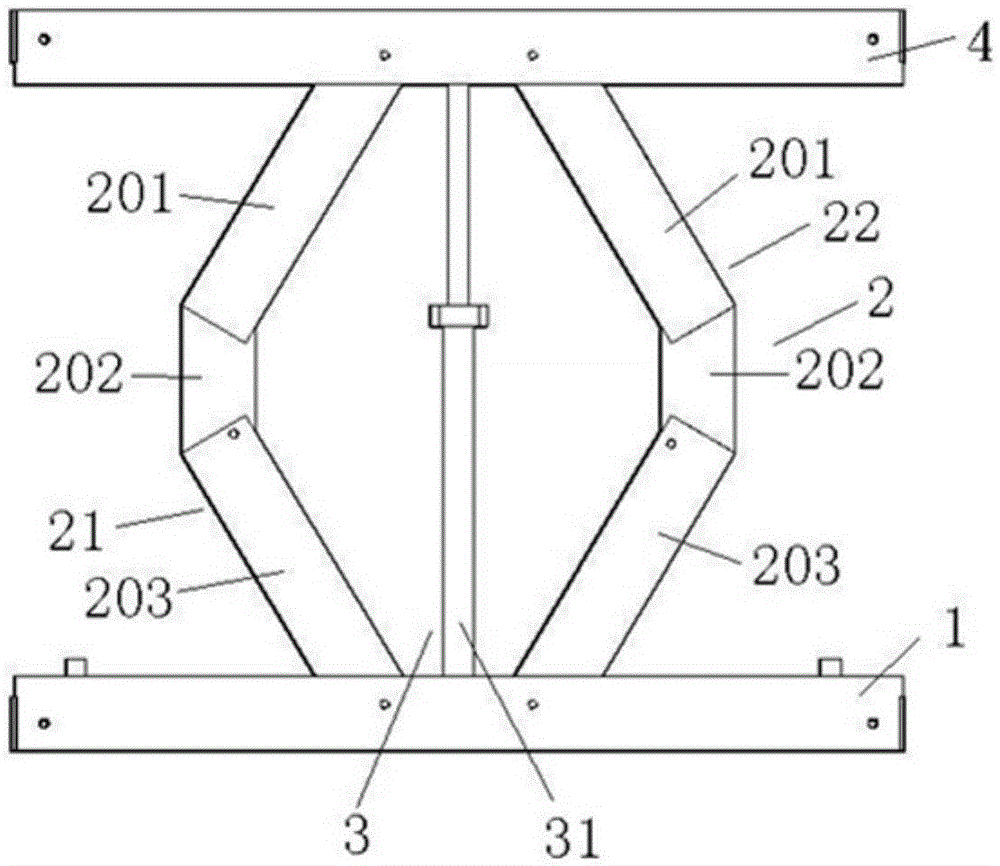

[0059] like figure 1 As shown, the basic structure of the universal support combination frame support unit includes a base plate 1, a top plate 4, a height adjustment device 2 and a support device 3; the height adjustment device 2 and the support device 3 are located between the base plate 1 and the top plate 4, and the One end of the height adjustment device 2 and the support device 3 is connected with the bottom plate 1, and the other end of the height adjustment device 2 and the support device 3 is connected with the top plate 4;

[0060] The bottom plate 1 and the top plate 4 are grooved plates vertically connected with baffles at both ends, each surface of the grooved plate is provided with a connection hole, and the two support units are realized through the cooperation of the connector and the connection hole. Connection; the two long side walls of the groove plate are provided with screw holes connecte...

Embodiment 1-1

[0065] The support device is a universal support combination frame support unit of threaded rod support type top:

[0066] like figure 1 As shown, the basic structure of the support unit of the universal support combination frame is as described above, and its supporting device is a threaded rod support type top 31, which is located in the middle of the height adjustment device 2;

[0067] like Figure 5 As shown, the threaded rod top includes a first round tube 311, a rotating handle 312 and a second round tube 313; one end of the first round tube 311 is provided with a threaded hole, and the other end is connected to the bottom plate 1; One end surface of two round pipes 313 is provided with a screw thread matched with the channel, and the other end is connected with the top plate 4; the rotating handle 312 is connected with the second round pipe 313, and the second round pipe 313 is adjusted into the first round pipe through the rotating handle 312 The length of the chann...

Embodiment 1-2

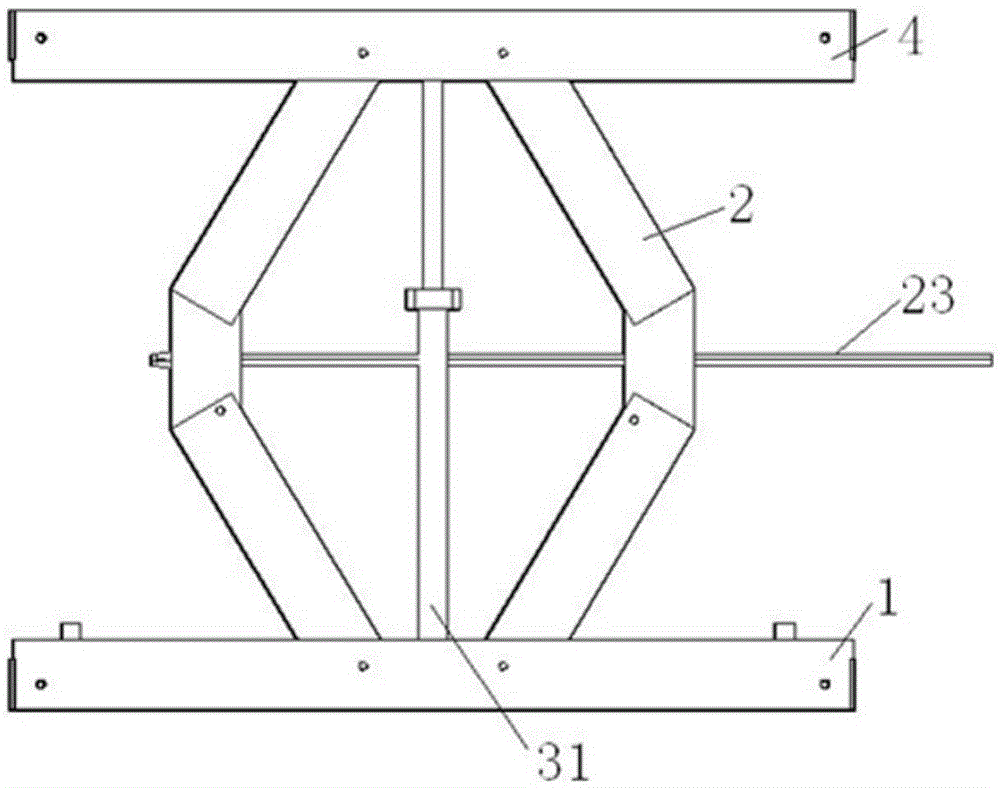

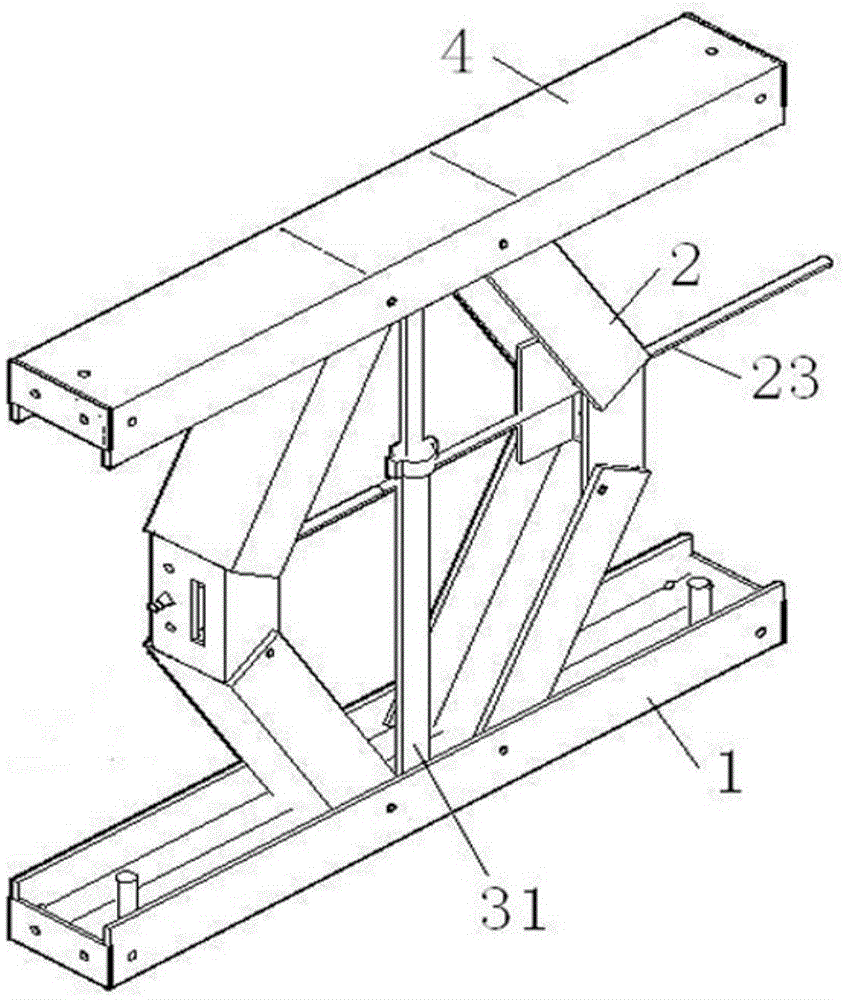

[0069] Universal support combination frame support unit with single threaded rotating rod 23:

[0070] The basic structure of this embodiment is the same as that of Embodiment 1-1, and the difference from Embodiment 1-1 is that: the height adjustment device 2 of the universal support combination frame support unit can also include one Single threaded swivel rod 23 (see figure 2 , image 3 );

[0071] like Image 6 As shown, the single threaded rotating rod 23 is made up of a cylindrical long rod and a rod end 233 of an unequal cylinder; the cylindrical long rod is respectively provided with a threaded section 231 and a non-threaded section 232; One end of the threaded section 232 is connected to the threaded section 231 , and the other end is connected to the rod end 233 ; the single threaded rotating rod 23 passes through the second connecting plate of the two movable connecting plates 21 , 22 in turn.

[0072] As a transformation of Embodiment 1-2 of the present invent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com