Infrared detector blind pixel detection system and method

A technology of infrared detectors and detection methods, applied in the field of infrared detectors, can solve problems such as failure of normal imaging, misjudgment of detection targets, and influence on observation, so as to improve detection efficiency and detection accuracy, facilitate blind element compensation, and prevent misjudgment Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

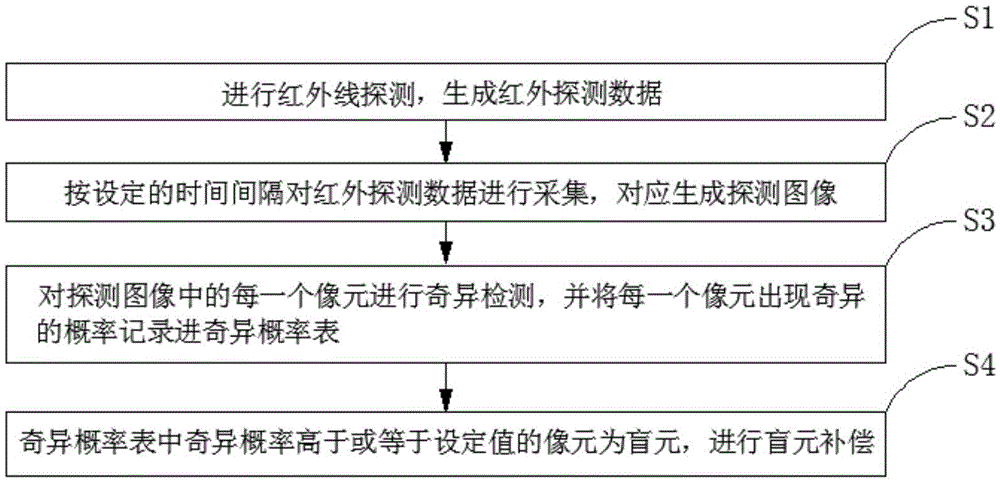

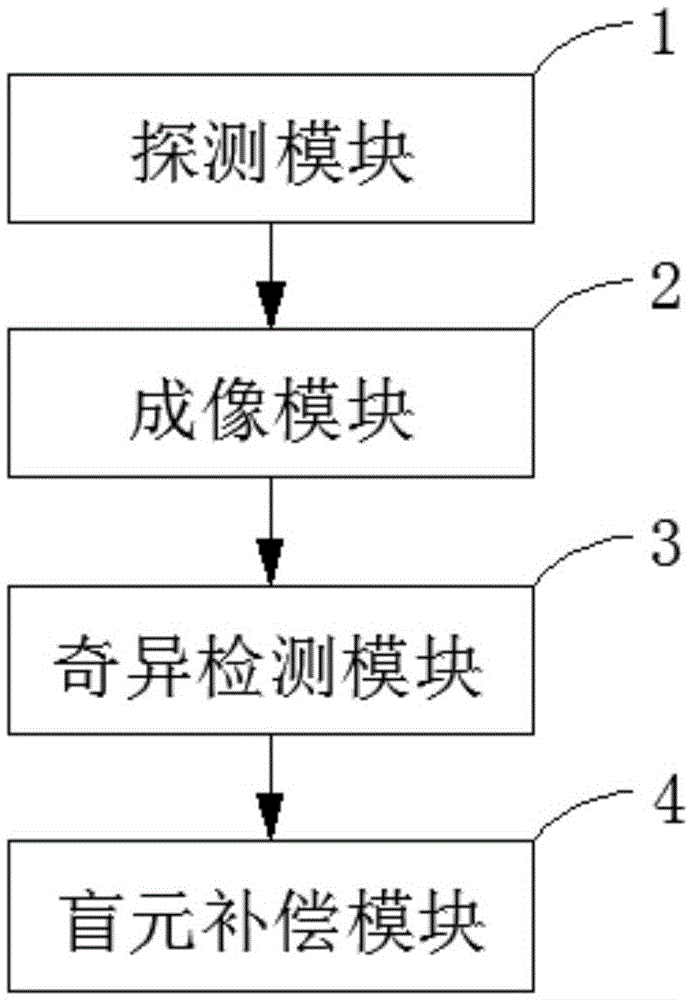

[0038] Such as figure 1 Shown, a kind of infrared detector blind element detection method comprises the following steps:

[0039] Step S1. Carry out infrared detection and generate infrared detection data;

[0040] Step S2. Collect the infrared detection data according to the set time interval, and generate detection images correspondingly according to the collected infrared detection data;

[0041] Step S3. Perform singularity detection on each pixel in the detection image, and record the probability of occurrence of singularity in each pixel into the singularity probability table;

[0042] Step S4. In the singular probability table, the pixels whose singular probability is higher than or equal to the set value a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com