Equipment detection method and detection equipment

A technology for testing equipment and equipment testing, applied in error detection/correction, instrumentation, electrical digital data processing, etc., can solve problems such as equipment not being discovered in time, and achieve the effect of convenient adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described in detail below through specific embodiments in conjunction with the accompanying drawings.

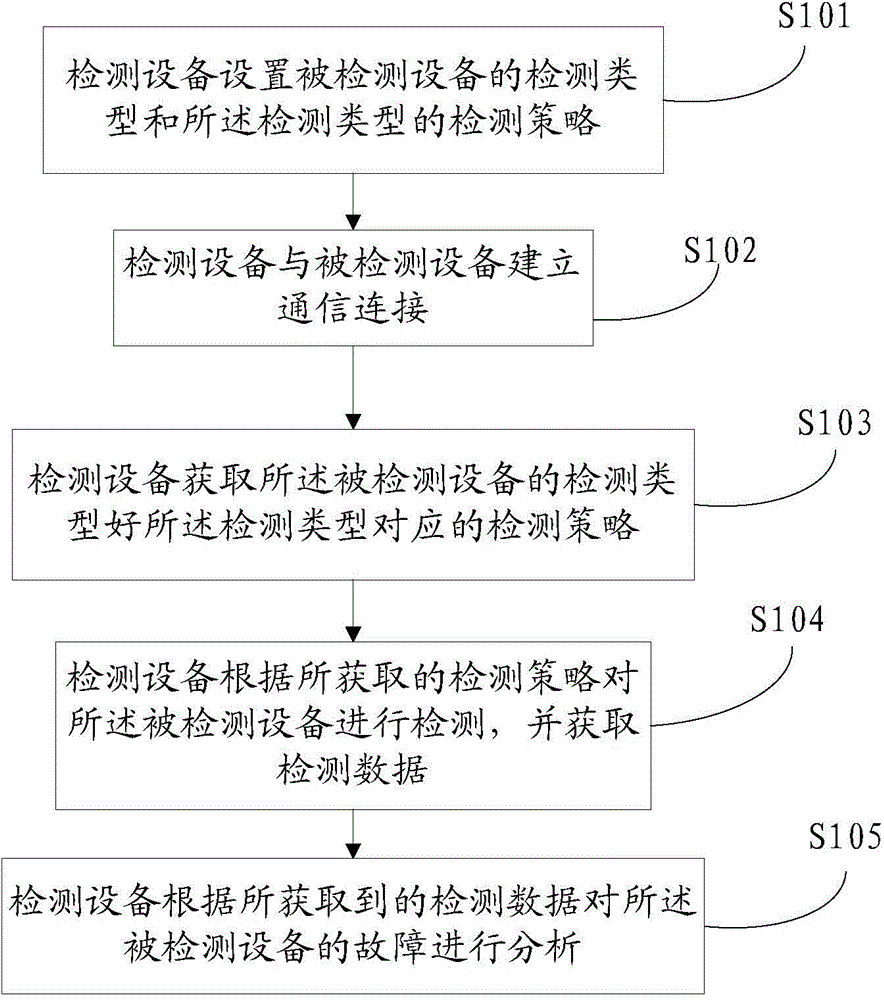

[0035] like figure 1 Shown is a schematic diagram of the device detection method provided by Embodiment 1 of the present invention, please refer to figure 1 ,include:

[0036] S101: The detection device sets a detection type of the detected device and a detection policy corresponding to the detection type. The detection type includes: detection of historical running status and performance detection, etc. The detection device setting the detection type of the detected device specifically includes: setting the detection granularity to detect the historical operation state and performance of the detected device respectively; or setting the detection granularity to detect the historical operation state and performance at the same time; or Set the detection granularity to only detect the historical operation status or performance; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com