Mechanical arm motion control delay measuring system based on visual inspection and method thereof

A technology of motion control and visual inspection, applied to manipulators, manufacturing tools, etc., can solve problems such as not considering robot differences, interference with normal robot operation, and distortion of measurement results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

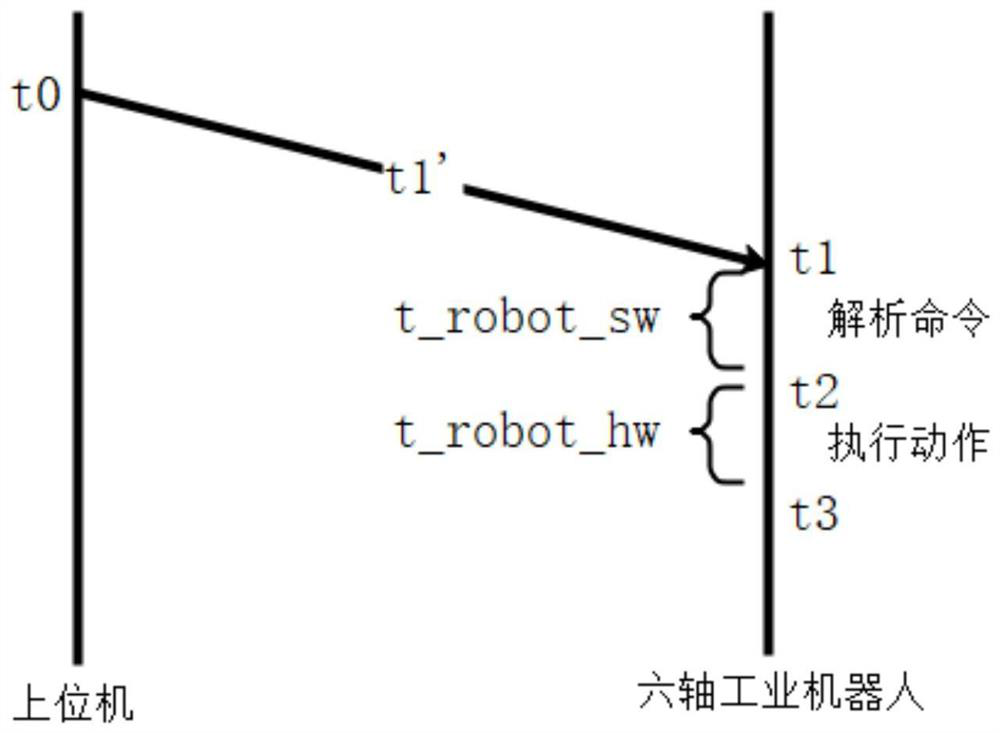

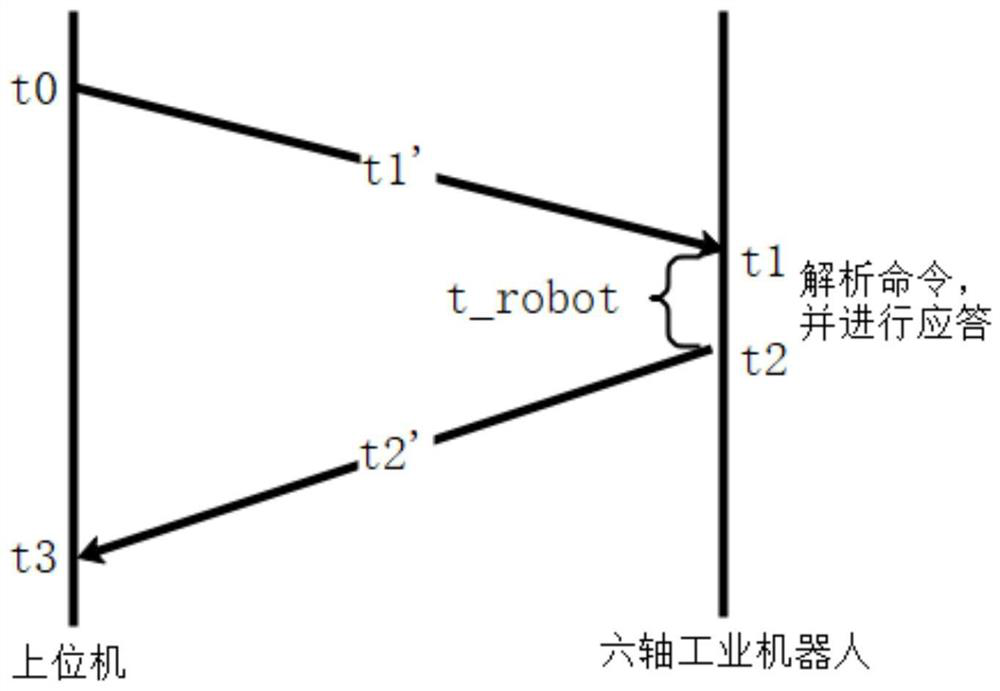

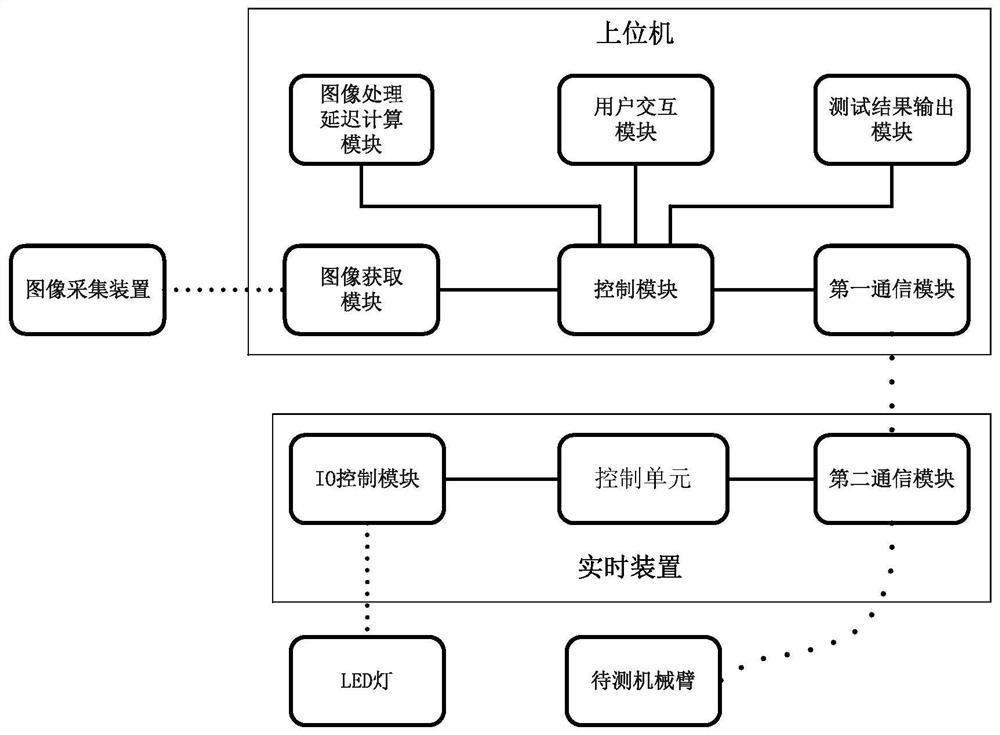

[0037] refer to image 3 , a kind of mechanical arm motion control delay measurement system based on vision detection of the present embodiment, comprises upper computer, real-time device, image acquisition device, LED light, upper computer is connected with real-time device, image acquisition device respectively, and real-time device is connected with LED respectively The light and the control interface of the robotic arm are connected. In this implementation, the measured object is the mechanical arm of a six-axis industrial robot, and the image acquisition device is a high-speed camera, specifically a pco.dimaxHS1 high-speed camera with a resolution of 800*600 and a frame rate of up to 13000FPS. The upper computer communicates with the real-time device through Ethernet. The real-time device communicates with the six-axis industri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com