Antenna reflector and antenna

A reflector and antenna technology, applied to antennas, electrical components, etc., can solve the problems of wasting materials, increasing processing costs, increasing costs, etc., and achieves the effect of improving front-to-back ratio indicators, reducing occupied space, and reducing material waste.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

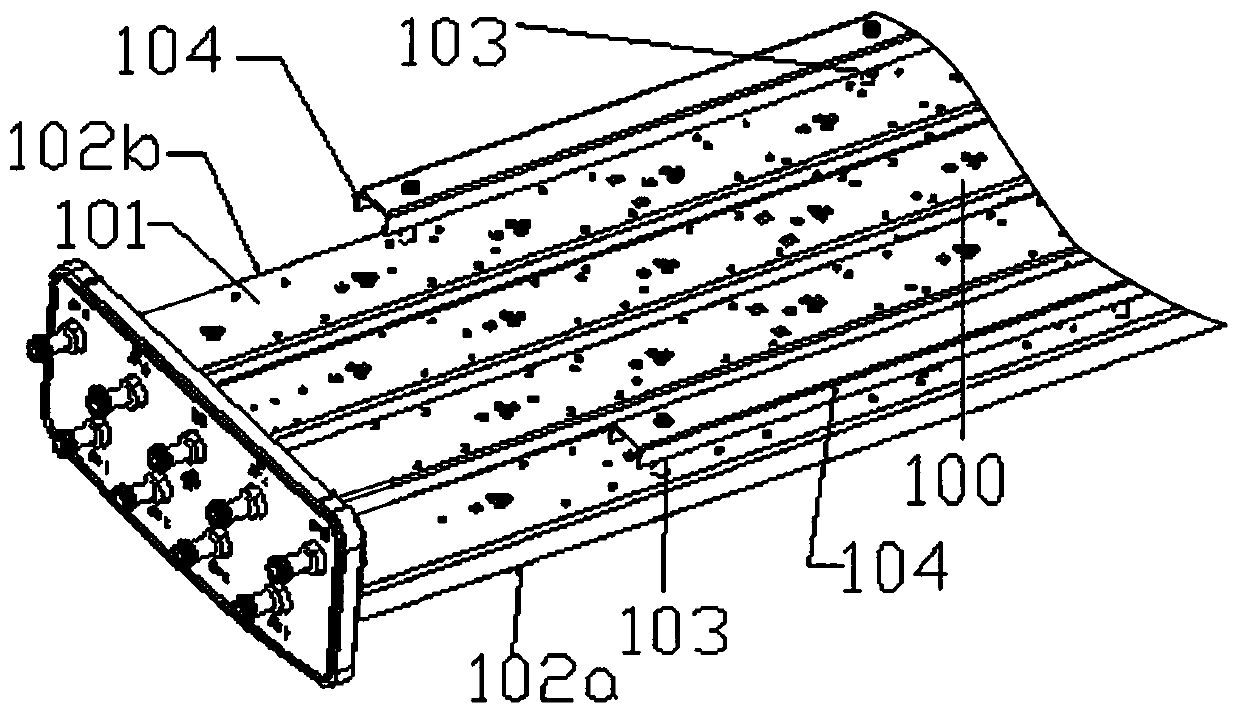

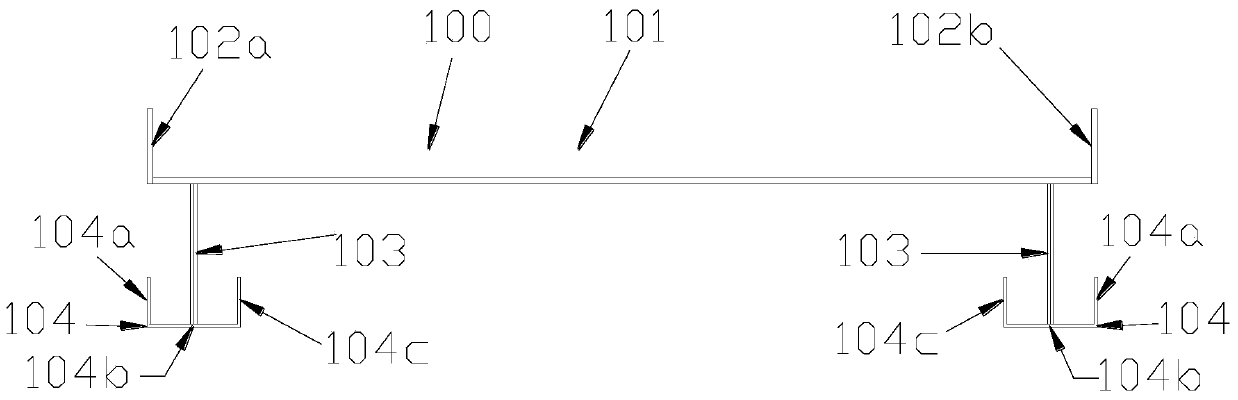

[0033] see figure 2 , which is a schematic diagram of the first embodiment of the antenna reflector based on the present invention.

[0034] In this embodiment, the reflecting plate 100 also includes a bottom plate 101 , two side plates 102 a , 102 b , several insulating support columns 103 , and two choke slots 104 .

[0035] Two choke slots 104 are symmetrically arranged on both sides of the lower side of the bottom plate, and each choke slot 104 is vertically arranged on the corresponding insulating support post 103 by the first loading section 104a located outside the corresponding insulating support post 103 103 at the bottom of the second loading section 104b and the third loading section 104c located inside the corresponding insulating support column 103 .

[0036] Specifically, the first loading section 104a and the third loading section 104c are symmetrically and vertically arranged on the left and right sides of the second loading section 104b. And the outer edges...

Embodiment 2

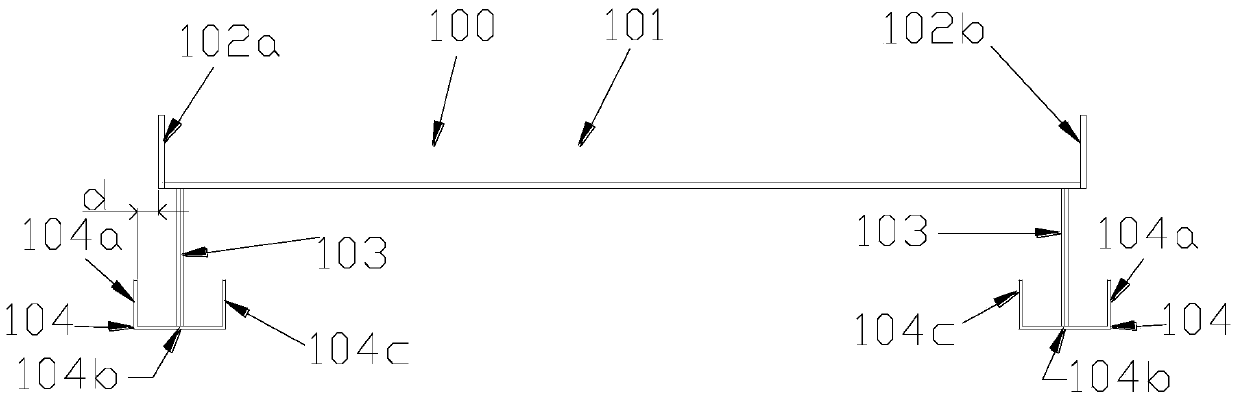

[0040] see image 3 , which is a schematic diagram of the second embodiment of the antenna reflector based on the present invention.

[0041] This embodiment is derived from the first embodiment, and its difference from the first embodiment is that the outer edge of the first loading section 104a of the choke groove 104 is longitudinally staggered from the outer edges of the side plates 102a, 102b, and the The outer edge of the first loading section 104a exceeds the outer edges of the side plates 102a, 102b, and the horizontal distance between them does not exceed 0.2 times of the working wavelength.

Embodiment 3

[0043] see Figure 4 , which is a schematic diagram of the third embodiment of the antenna reflector based on the present invention.

[0044] This embodiment is derived from the first embodiment, and its difference from the first embodiment is that the outer edge of the first loading section 104a of the choke groove 104 is longitudinally staggered from the outer edges of the side plates 102a, 102b, and the The outer edges of the side plates 102a, 102b exceed the outer edge of the first loading section 104a, and the horizontal distance between them is no more than 0.2 times the working wavelength.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com