Fuel high pressure pump with outlet valve

A high-pressure pump and outlet valve technology, which is applied to fuel injection pumps, fuel injection devices, special fuel injection devices, etc., to achieve the effect of low cost and noise avoidance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

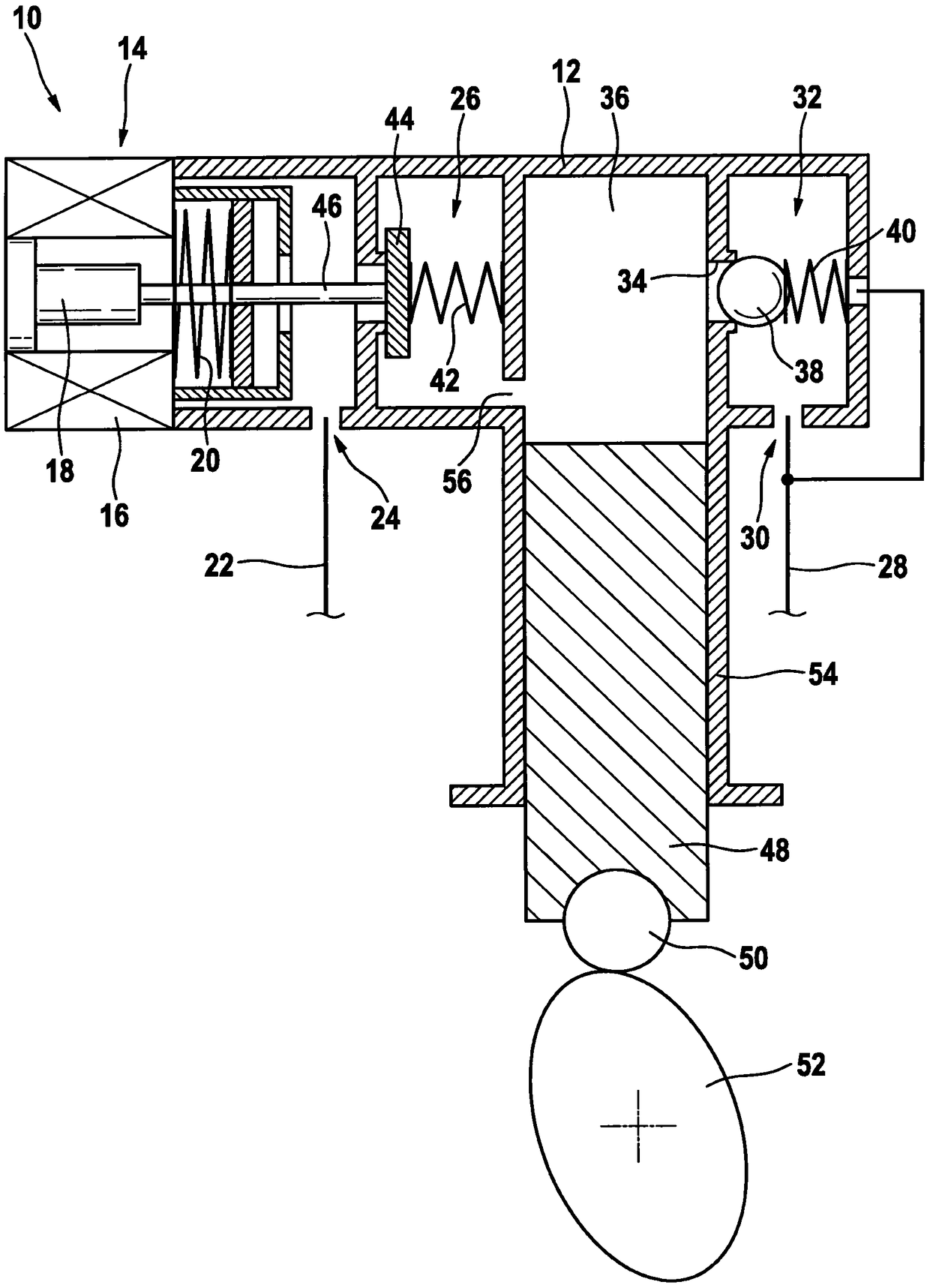

[0018] figure 1 A simplified schematic diagram of the high-pressure fuel pump 10 is shown in axial section. The high-pressure fuel pump 10 is a component of a fuel system (not shown) of an internal combustion engine (not shown) of a motor vehicle. The fuel high-pressure pump 10 has a housing 12, as shown in the left part of the figure, an electromagnet 14 is arranged in the housing 12, and the electromagnet 14 has a magnet coil 16, an armature 18, and an armature spring 20.

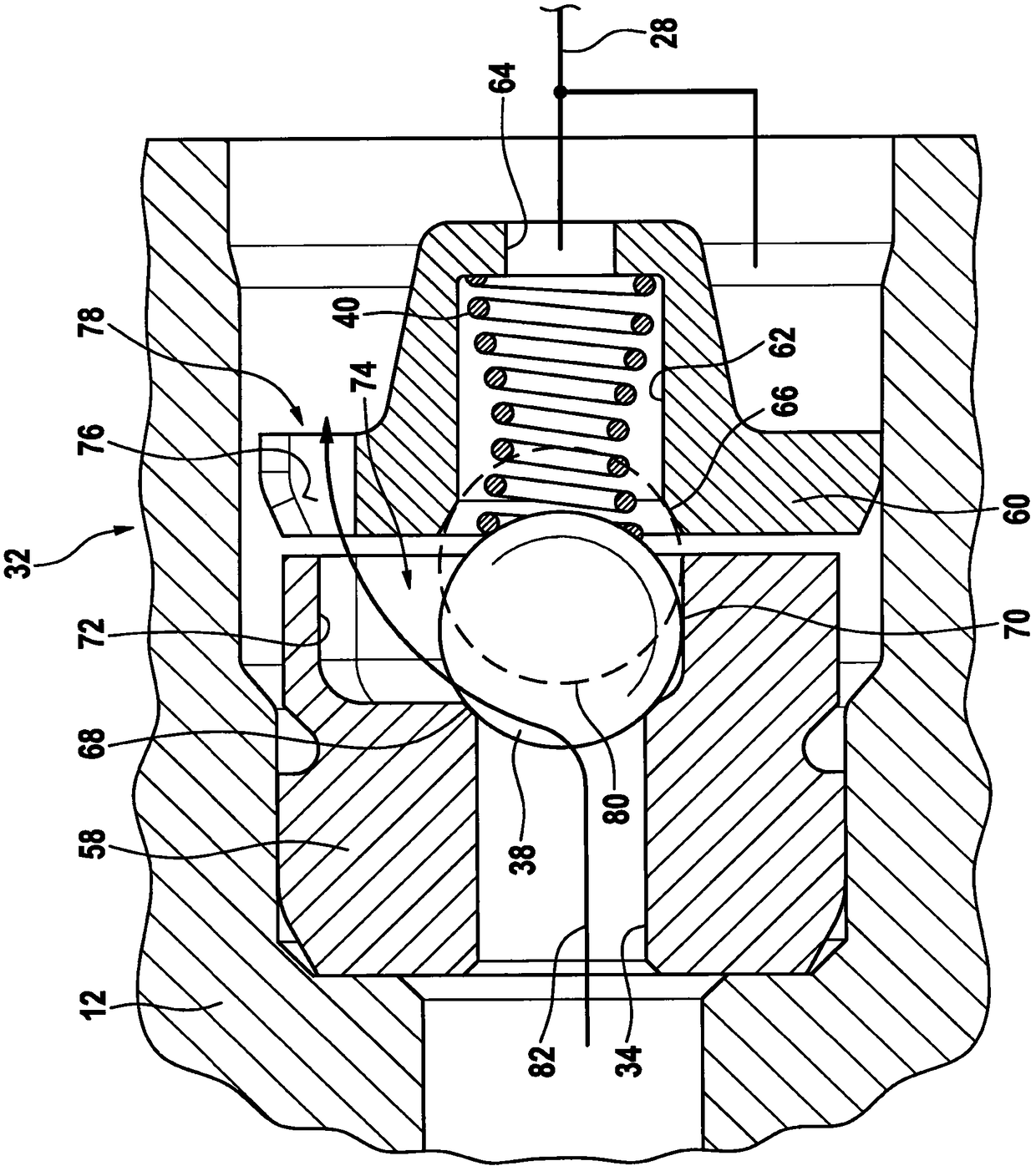

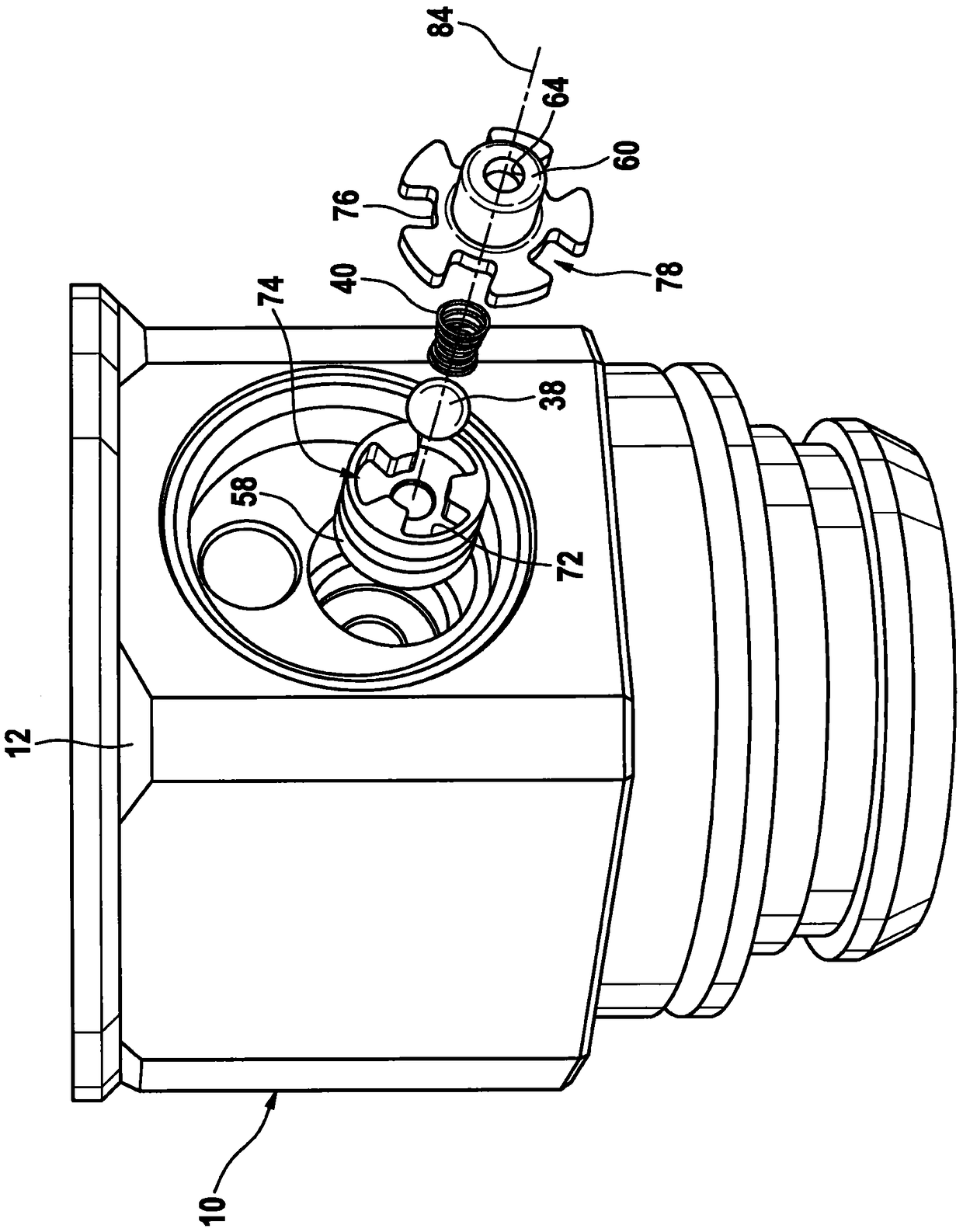

[0019] In addition, the high-pressure fuel pump 10 includes an inlet 24 and an outlet 30. The inlet 24 has an inlet valve 26 and the inlet 24 is connected to a low-pressure pipe 22, and the outlet 30 has an outlet valve 32 and the outlet 30 is connected to a high-pressure pipe. 28 connections. The high-pressure accumulator ("pressure accumulator") connected to the high-pressure pipe 28 is not shown here. In the open state, the outlet valve 32 is hydraulically connected to the supply chamber 36 through the ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap