Fill level sensor

A technology of liquid level sensor and potentiometer, which is applied in the direction of float liquid level indicator, liquid level indicator, instrument, etc., can solve the problem of high cost and achieve the effect of low cost and low corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

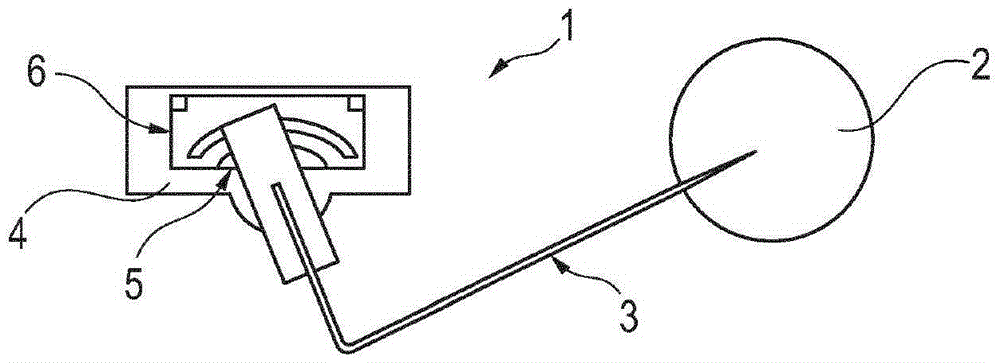

[0021] figure 1 A level sensor 1 with a lever arm 3 holding a float 2 is shown. This liquid level sensor 1 is used in a fuel tank not shown. The lever arm 3 is mounted pivotably on the carrier 4 and pivots depending on the fill level of the fuel arranged in the fuel tank. The swing of the lever arm 3 is detected by a potentiometer 5 . The potentiometer 5 has a carrier element 6 arranged on a carrier 4 .

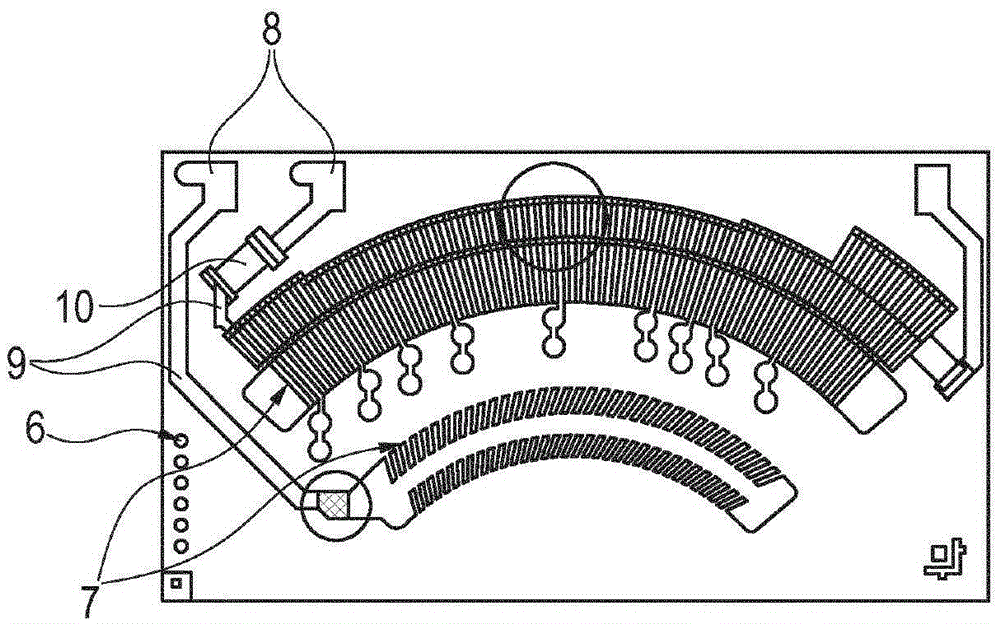

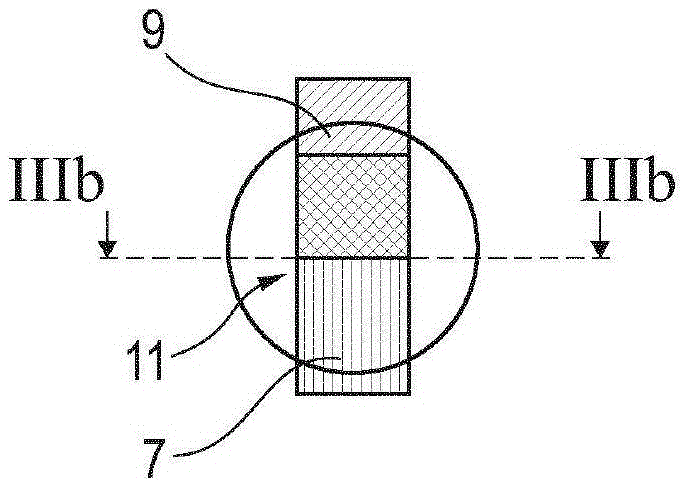

[0022] The carrier element 6 of the potentiometer 5 is in figure 2 Enlarged display. Arranged on the carrier element 6 are function-dependent structures, such as slide rail structures 7 and electrical connection areas 8 . Furthermore, the carrier element 6 also has inactive structures, such as conductor structures 9 of the lead-in lines, carrier conductors in the resistive region and switching conductors. The resistor structure 10 forms an ohmic resistor in the conductor structure 9 . A contact bridge, not shown, arranged on the lever arm 3 slides on the slide rail st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com