Manufacturing method of display substrate of display panel

A technology for display substrates and substrates, used in manufacturing tools, semiconductor/solid-state device manufacturing, semiconductor/solid-state device testing/measurement, etc., can solve the problems of narrow process window, expensive, time-consuming and cutting samples, etc., to prevent damage. , Reduced manufacturing cost, improved effect of adjustable process window

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order for those skilled in the art to better understand the technical solutions of the present invention, a display panel and a display device provided by the present invention will be further described in detail below with reference to the drawings and specific embodiments. Wherever possible, the same reference numbers will be used throughout the drawings to refer to the same or like parts.

[0029] An aspect of the present invention provides a flexible OLED structure for a half-cut process.

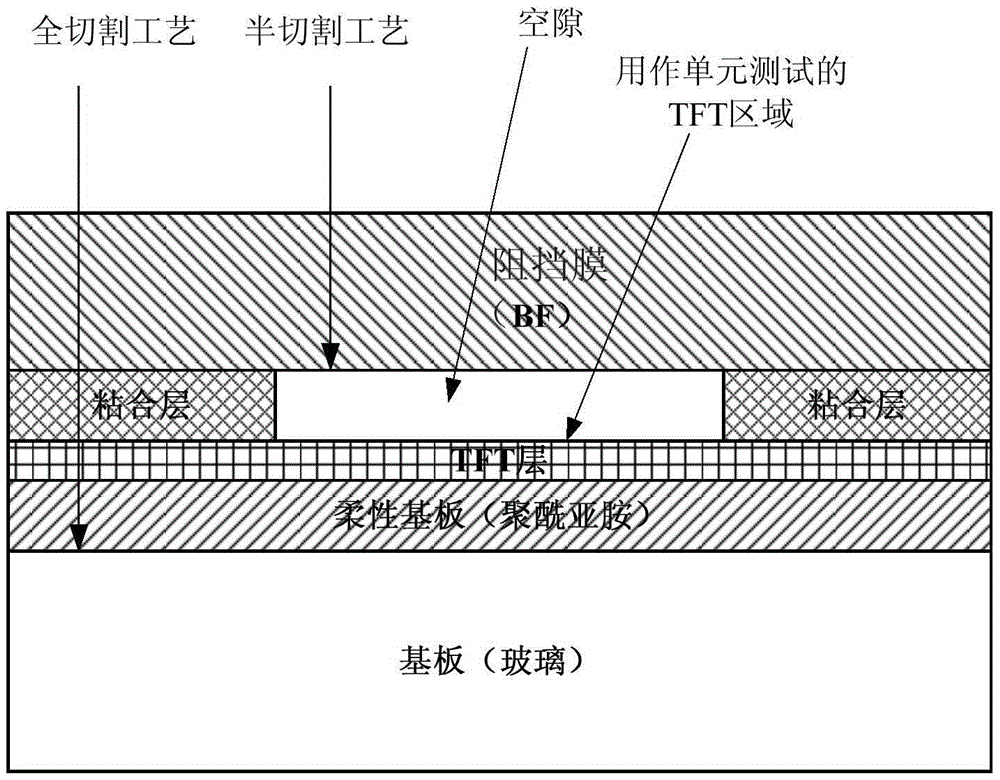

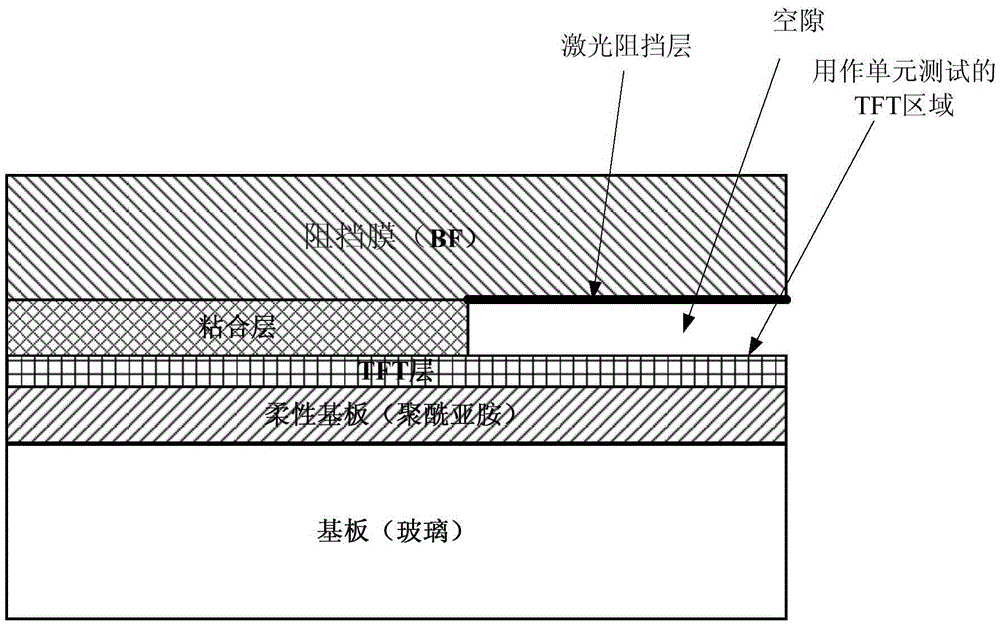

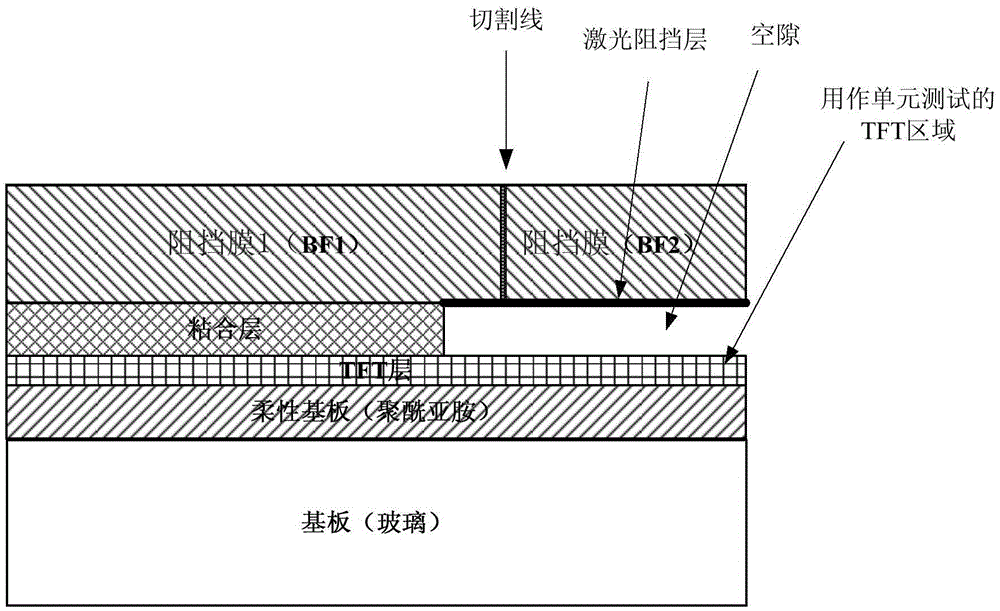

[0030] figure 1 A cross-sectional view of a portion of a flexible OLED structure for forming a flexible OLED display panel is shown. The flexible OLED structure may include a barrier film, an adhesive layer, a TFT layer, a flexible substrate and a rigid substrate. The rigid substrate, which may be made of glass, is used to support the flexible substrate and components formed on the flexible substrate during manufacturing and testing. The rigid substrate can be removed durin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap