Oil-filtering electric fryer

An electric frying and oil filtering technology, which is applied to the utensils for frying things in oil, household utensils, applications, etc., can solve the problems of safety and oil filtering structure need to be further improved, poor structural design, etc., to achieve convenient cleaning , The effect of good safety and reasonable structure design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

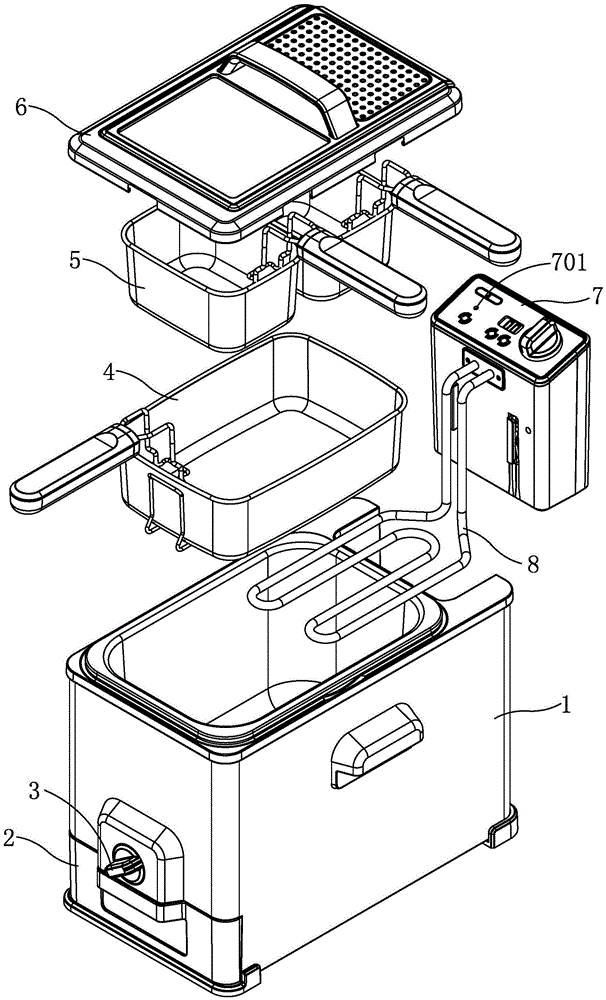

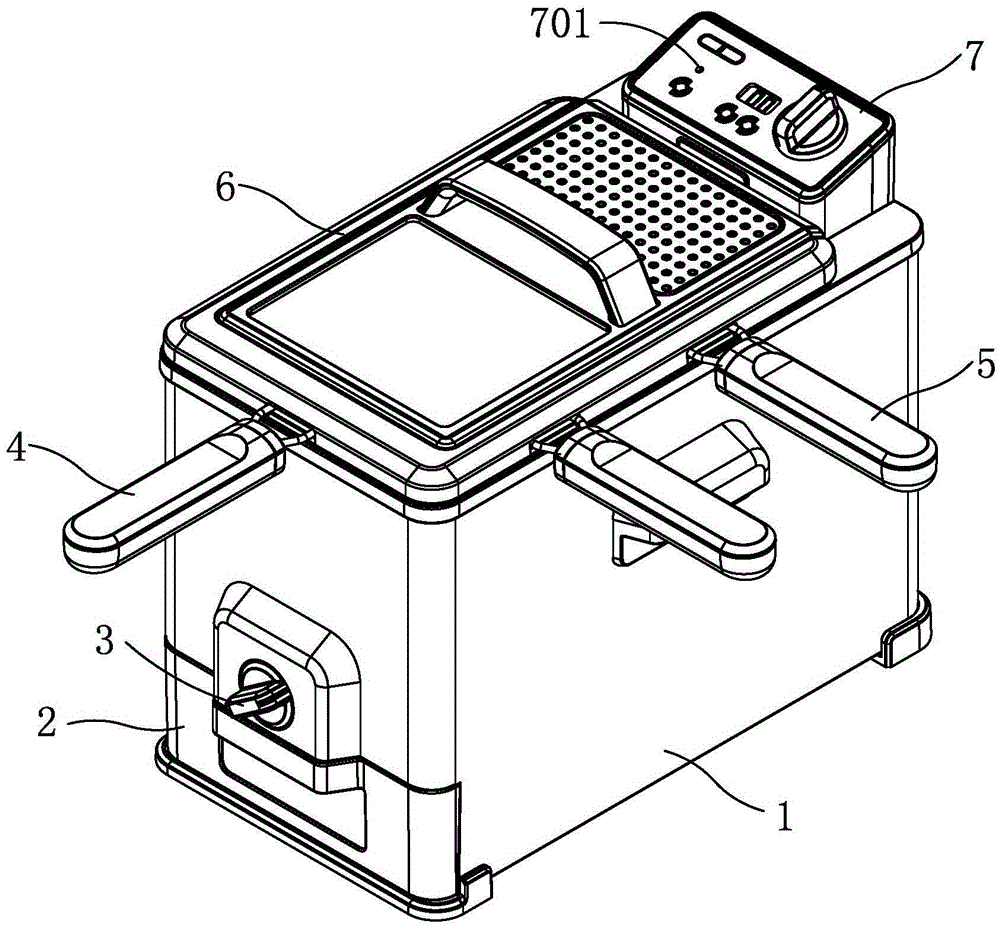

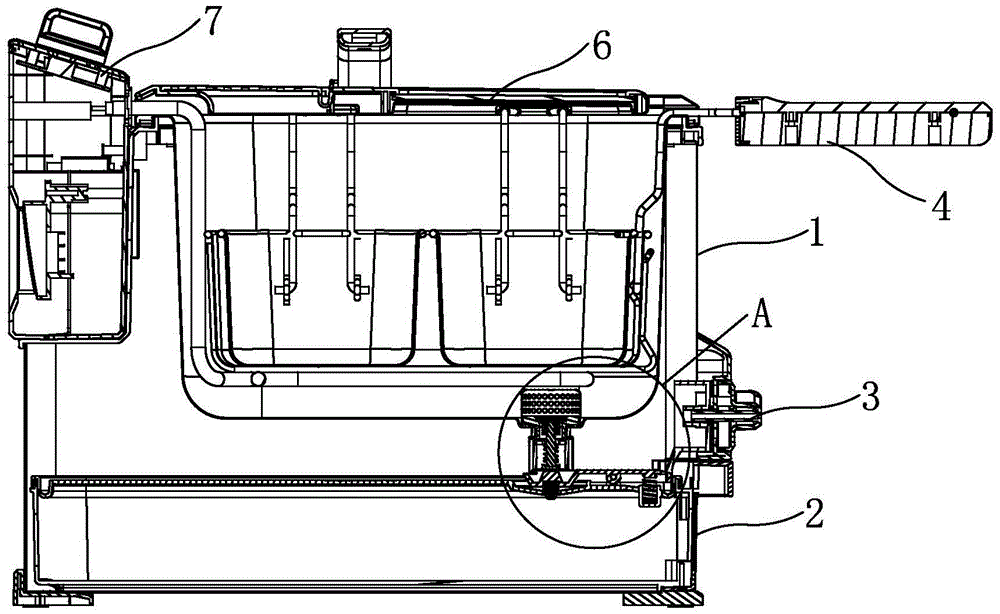

[0028] Now in conjunction with the accompanying drawings, the structure and use of the present invention will be further described. like Figure 1 to Figure 12 As shown, the shell cover 6 of the electric fryer is provided with a transparent plate, a ventilating plate and a handle, an inner pot 11 is arranged in the housing 1, and a base is provided on the shell at the bottom of the inner pot, and an oil box 16 is arranged in the base; 3 Set above the outlet of the oil box at the base of the shell, the knob side of the oil box is provided with a cover plate 2 and a limit groove, the cover plate and the oil box are connected as one; There is an oil pouring hole, and the oil pouring hole is provided with an oil hole cover. The oil discharge assembly 9 is fixedly arranged on the oil discharge hole of the inner pot, the oil discharge assembly at the oil discharge hole is provided with a filter screen 10, the heating pipe is connected with the control box, the heating pipe is L-sha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com