flat mop cleaning bucket flat mop

A technology for a flat mop and a cleaning bucket is applied to the field of mop cleaning buckets, which can solve the problems of high labor intensity, inability to operate continuously, and large volume of the bucket body, and achieve flexible and light up and down movements, good dehydration effect, and good cleaning effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

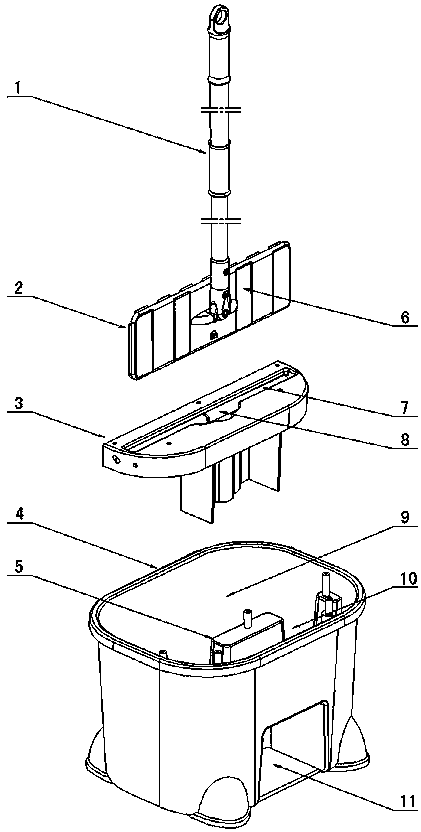

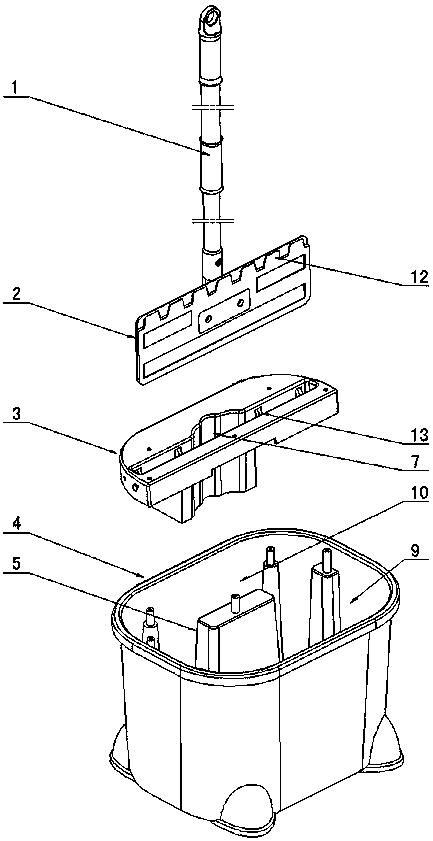

[0021] Figure 1 to Figure 5 As shown, the invention creates a specific embodiment of a flat mop cleaning barrel, which includes a barrel body 4 and a dehydration support seat 5, the barrel body 4 is provided with a cleaning area 9 and a dehydration area 10, and the dehydration support seat 5 is provided with On the barrel body 4 of the dehydration area 10, a dehydration support 3 is fixed on the dehydration support seat 5, and the dehydration notch 7 for the up and down movement of the flat drag main board 2 is provided on the dehydration support 3, corresponding to the mop side of the flat drag main board 2 The groove wall of the dehydration notch 7 is provided with a dehydration mechanism.

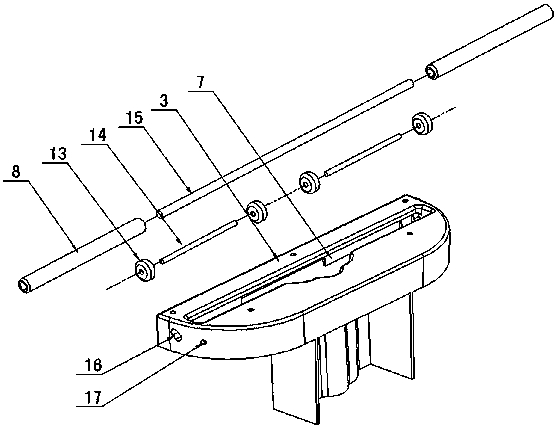

[0022] In order to facilitate dehydration, the dehydration mechanism includes a dehydration roller 8, a dehydration roller shaft 15, and at least one dehydration roller shaft 15 corresponding to the length of the mop is arranged on the mop side groove wall of the dehydration slot 7, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com