A hand-held electric paint spraying machine and its working method

A sprayer and hand-held technology, which is applied in the field of hand-held electric paint sprayers, can solve the problems of unstable air pressure, high price, and limitation of equipment, and achieves the effects of strong construction practicability, simple structure, and easy portability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The present invention will be described in detail below in conjunction with the accompanying drawings.

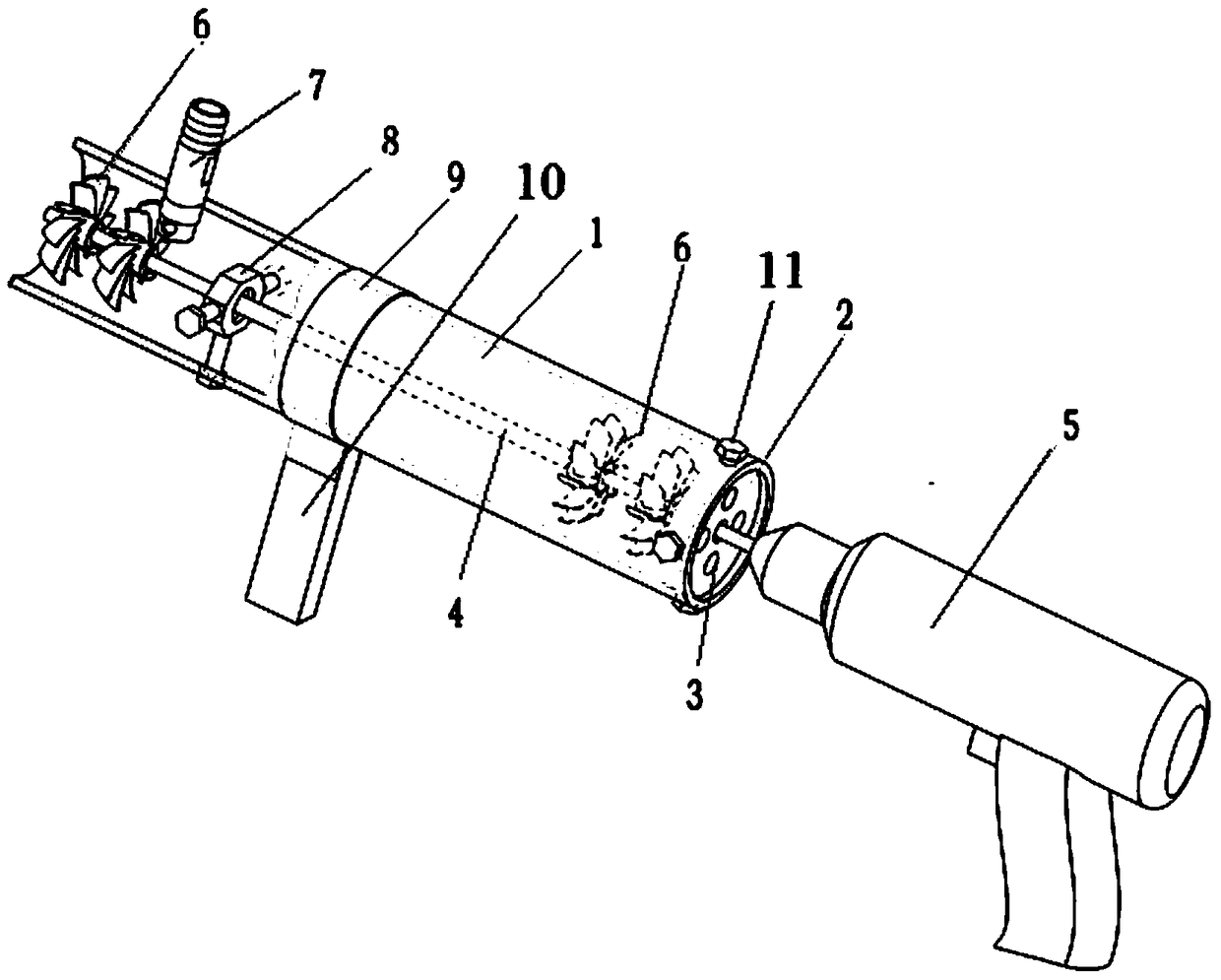

[0010] In the figure, the hand-held electric paint spraying machine includes a tubular cylinder body 1. The cylinder body is a cylindrical light metal tube in the present invention. A support plate 2 is installed on one end of the cylinder body 1, and the support plate 2 is fixed on the cylinder body by screws 11. On the body 1, the other end of the cylinder body 1 is the discharge port, the center of the support plate 2 has a socket, and at the same time, with the socket as the center, several through holes 3 are set on the end face of the support plate 2, and the main shaft 4 passes through the socket. The hole extends into the barrel 1, and an electric device is installed on the main shaft 4 outside the barrel 1. The electric device drives the main shaft 4 to rotate. The electric device is preferably a pistol drill 5, and the clamping end of the pistol drill 5, tha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com