Paint spraying operation isolation structure

A technology for isolating structures and operations, applied in spray booths, spraying devices, coatings, etc., can solve the health hazards of operators, affect the health of operators and other problems, reduce the health hazards of operators, facilitate adjustments, and facilitate spray guns The effect of the angle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

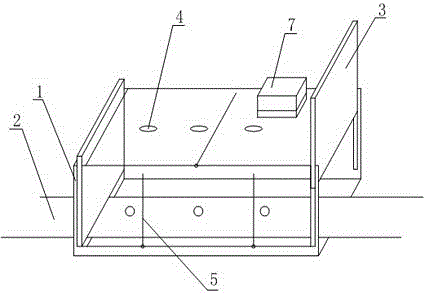

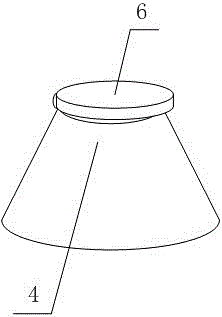

[0019] Such as figure 1 and figure 2 The shown isolation structure for painting operation includes a box body 1, and also includes a conveyor belt 2 passing through the inside of the box body 1 along the long axis direction of the box body 1, and the two sides of the long axis direction of the box body 1 are provided with There is a switchable box door 3, each surface of the box body 1 is provided with a number of spray gun jacks 4, the aperture of the spray gun jacks 4 increases linearly from the outside to the inside, and the box body 1 is made of transparent material As a result, the casing of the box 1 is also provided with a ventilation device 7 with an air inlet facing the inside of the box 1; the openings of the spray gun sockets 4 are hinged with isolation plates 6 . In this embodiment, the conveyor belt 2 is located in the middle of the inner bottom surface of the box body 1, and the box doors 3 on the left and right sides of the box are two boards that can be freel...

Embodiment 2

[0021] Such as figure 1 and figure 2 In the shown isolation structure for painting work, on the basis of Embodiment 1, several wipers 5 are arranged on the inner surface of the box body 1, and the several wipers 5 are controlled by a control switch. During the working process of this embodiment, the paint scattered on the inner surface of the box 1 is cleaned up in time by the wiper 5, so as to prevent the paint from blocking the line of sight and affecting the operator's observation of the inside of the box 1. Using one control switch to simultaneously control the power on and off of all the wipers 5 avoids complicated operations caused by individual control and improves the ease of use of the present invention.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com