Composite tube end surfacing layer weld joint polishing equipment

A technology of grinding equipment and surfacing layer, which is applied in the direction of grinding/polishing equipment, metal processing equipment, grinding machines, etc., which can solve the problems of high grinding cost, long grinding time, and affecting grinding efficiency, and solve the problem of steel pipe Circumferential runout, solving the grinding wheel transition grinding, improving the effect of precision and efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with the accompanying drawings.

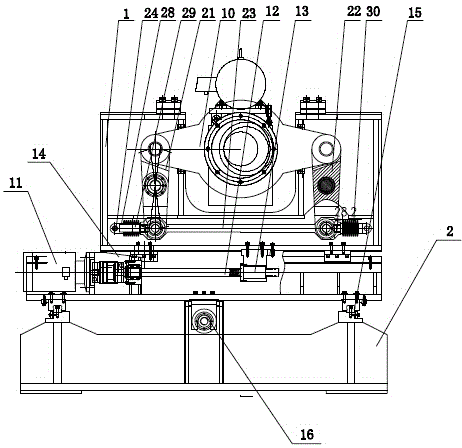

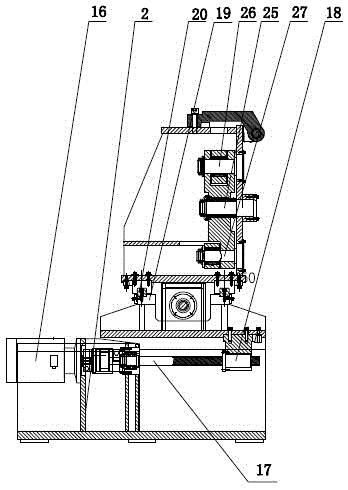

[0016] Such as Figure 1-3 As shown, the present invention is a composite pipe end welding seam grinding equipment, which is mainly used for grinding

[0017] The weld seam at the overlap between the surfacing layer and the liner makes a smooth transition. Including the frame 1, the base 2, the grinding mechanism arranged on the frame 1 and the grinding feeding mechanism arranged between the frame 1 and the base 2, the grinding mechanism and the grinding feeding mechanism are used together to realize Grinding of lap joints of pipe end sealing and welding layers in composite pipes.

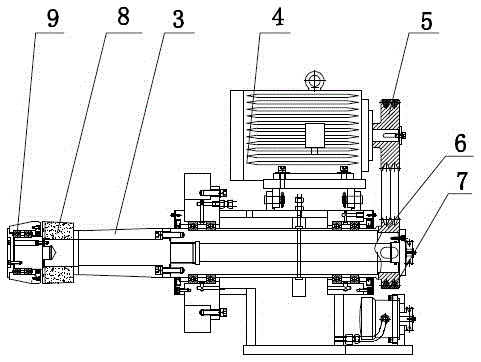

[0018] The grinding mechanism comprises a drive shaft 3, a frequency conversion motor 4 arranged above the drive shaft 3, an upper pulley 5 connected to the output end of the frequency conversion motor 4, and one end of the drive shaft 3 is sleeved with a lower pulley 6, an upper pulley 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com