Small plate polishing and compressing machine

A technology for compactors and plates, applied in grinding machines, machine tools suitable for grinding workpiece edges, grinding workpiece supports, etc., can solve the problems of insecurity, high work intensity, corrosion appearance of plates, etc., to ensure long-term protection. Safe use, improved clamping efficiency, light weight design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

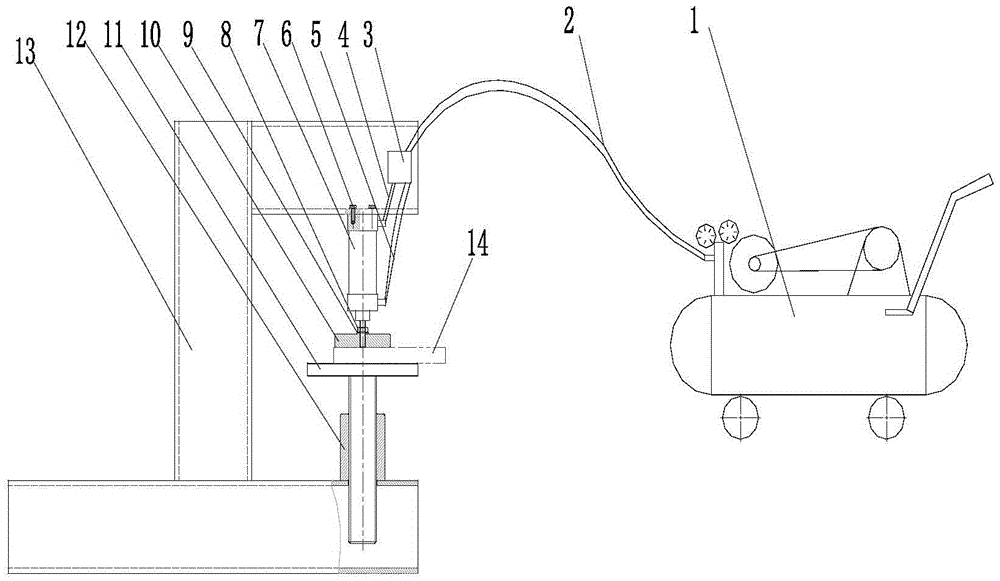

[0018] Now in conjunction with accompanying drawing, the present invention will be further described, as figure 1 As shown, including frame, air compressor, cylinder, air pipe, pressure plate, supporting plate, transfer switch. The present invention adopts the pneumatic transmission mode, the frame is made of channel steel, the cylinder is placed at the lower end of the cross arm of the frame, a changeover switch is arranged on the cross arm of the frame, and nuts are welded on the frame seat.

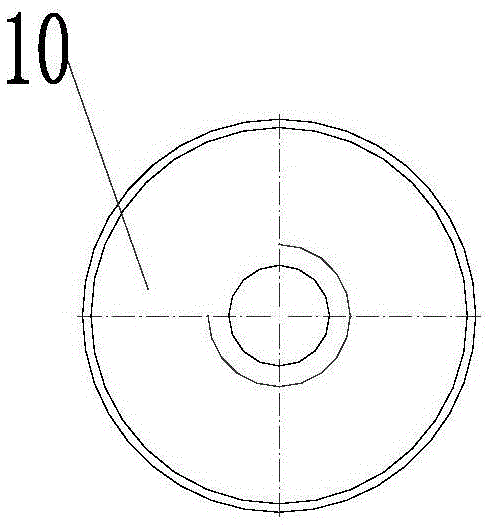

[0019] A cylinder is installed at the lower end of the cross arm of the frame, and a pressure plate is installed at the end of the cylinder piston screw rod ( figure 2 ), screw the limit nut on the back of the pressure plate.

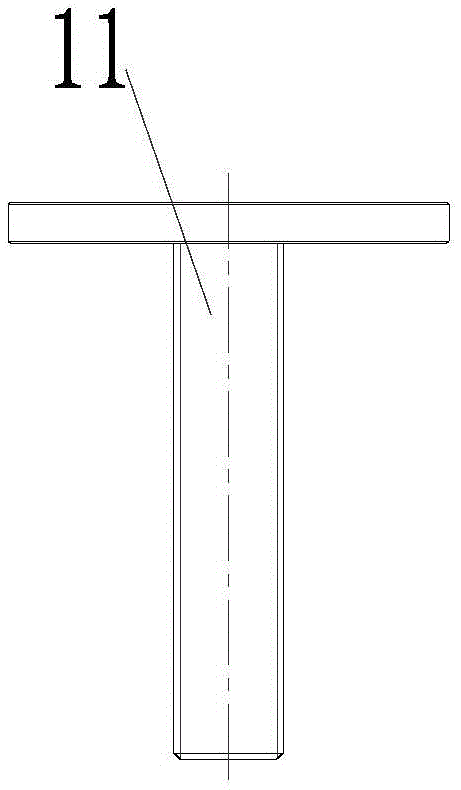

[0020] Pallet ( image 3 ) and nuts welded on the frame ( Figure 4 ) are screwed together, the supporting plate can be lifted up and down. When pressing plates with different thicknesses, the stroke of the cylinder piston can be kept unchanged, thus ensurin...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap