Long stroke water knife based on silk pole transmission

A technology of screw drive and large stroke, which is applied to the sealing of engines, engine components, manufacturing tools, etc. It can solve the problems of limited length and low transmission accuracy, achieve beautiful appearance, improve transmission accuracy, and ensure machining accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

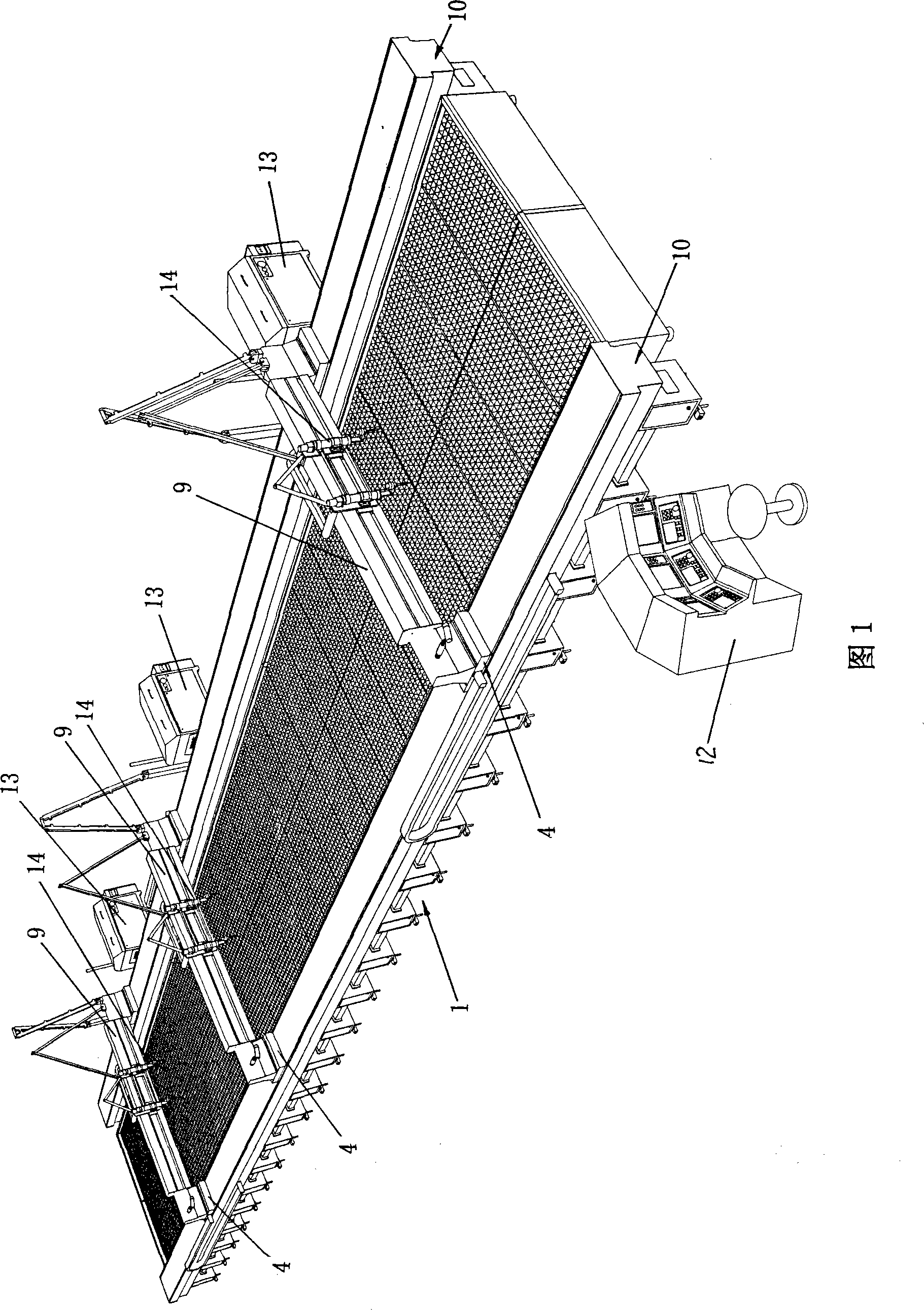

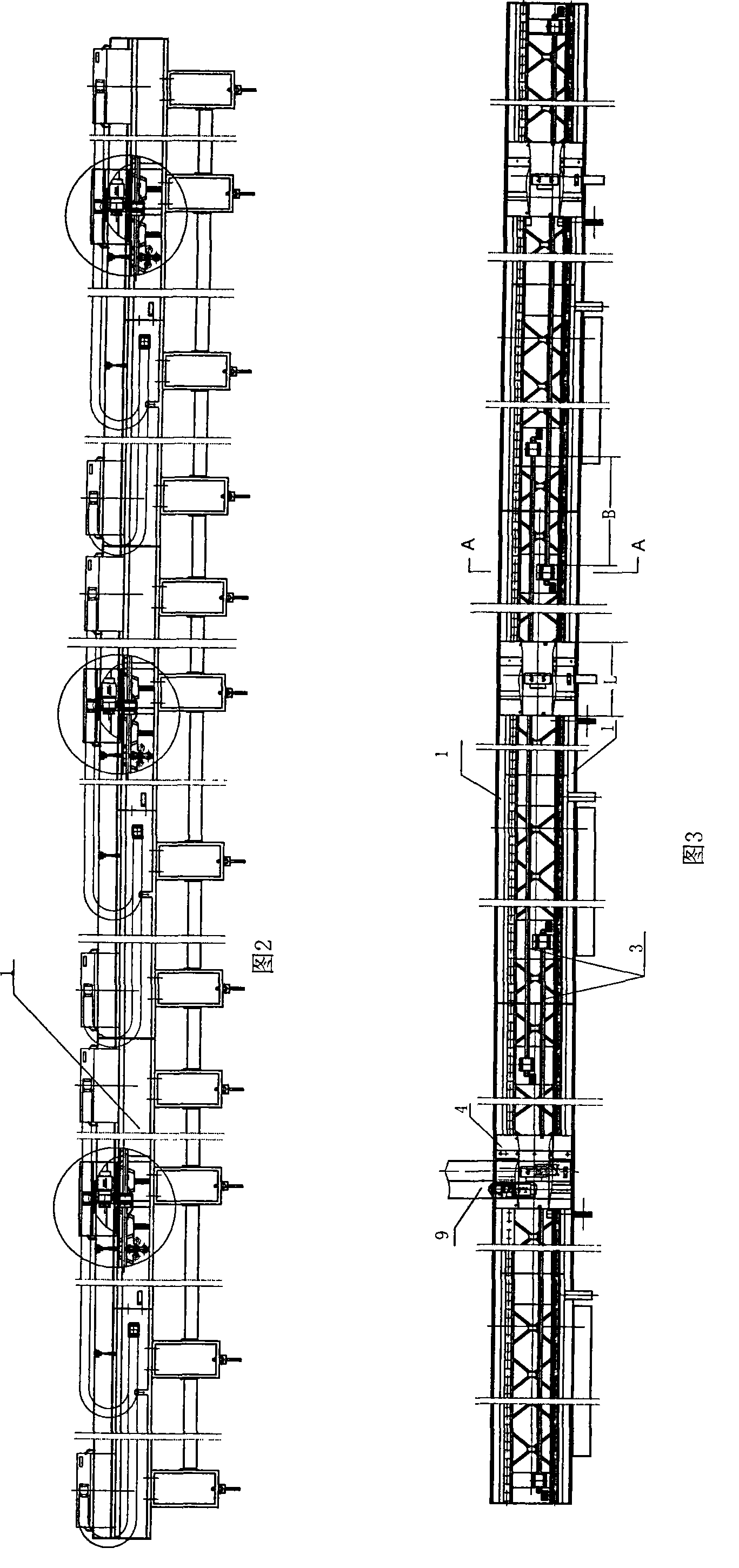

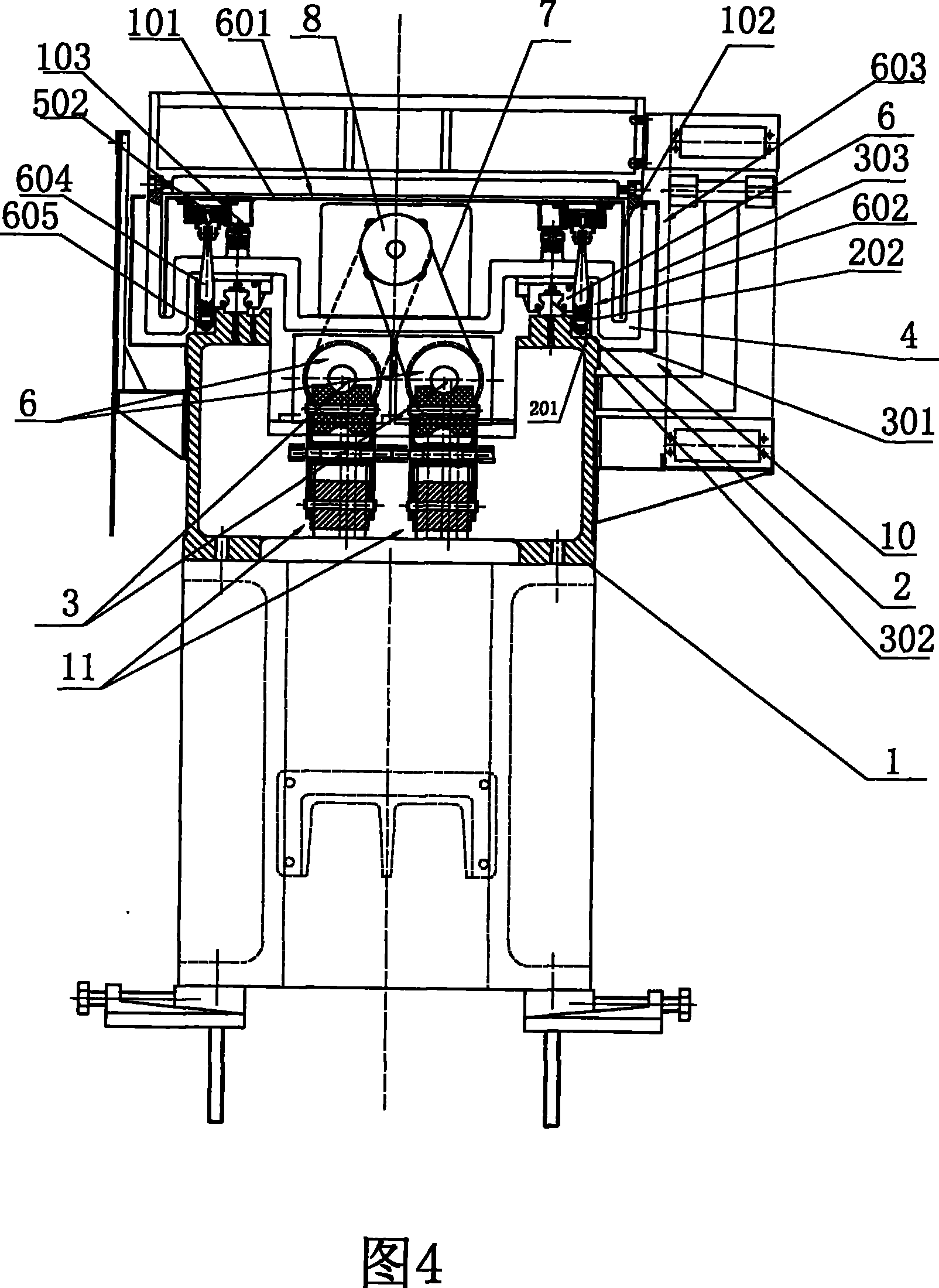

[0031] As shown in Figure 1-6.

[0032]A large-stroke waterjet based on screw drive, including two longitudinal guide rail frames 1 arranged in parallel at the front and rear. The longitudinal rail frame 1 can be connected or spliced by two or more segments, as shown in Figure 1 , 2, the guide rail frame 1 of the present embodiment has 3 sections connected together, and the horizontal upper surface of each section of longitudinal guide rail frame 1 is provided with guide rails 2 in parallel. Screw rod 3 (the length of each ball screw rod 3 can reach 14 meters, generally 8-11 meters, and its diameter can be between 40-60 mm, so the aspect ratio can reach more than 200), the ball The two ends of the screw rod 3 are tightened and fixed in the guide rail frame 1, which is equivalent to tightening it to reduce the sag of the screw rod. When the length of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com