Intelligent lifting platform for electricity maintenance and using method thereof

A lifting platform and power maintenance technology, which is applied in the direction of lifting devices, lifting equipment safety devices, etc., can solve problems such as tilting, low safety, and affecting users' daily power consumption, and achieve the effect of improving stability and preventing dumping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

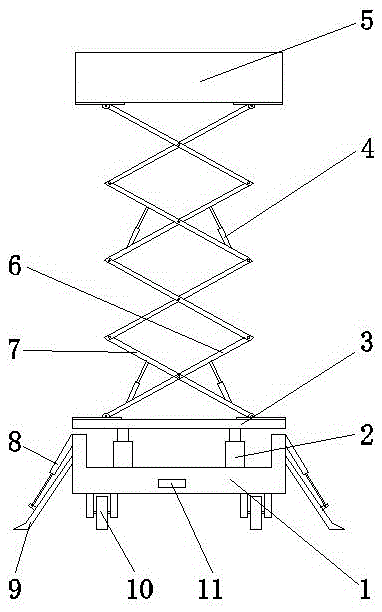

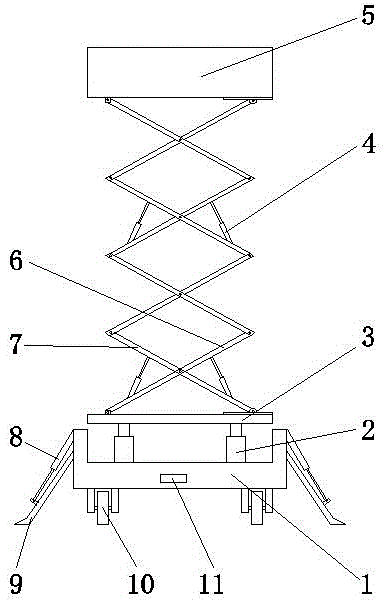

Embodiment 1

[0052] see figure 1 , an intelligent lifting platform for electric power maintenance, including a hydraulic system, an electrical system, a base 1, a maintenance platform 5 and a lifting device, the electrical system includes an electric control box, a controller, and the hydraulic system includes a hydraulic station; the leveling device is arranged on the base 1 It is used to adjust the intelligent lifting platform for power maintenance to a horizontal position to prevent it from tipping over when in use; the first-level lifting platform 3 is located above the base 1 and is set on the leveling device; the supporting device is set on the base 1, it plays a role in improving stability and further preventing dumping during use; the lifting device is set on the first-level lifting platform 3, which is responsible for the main lifting task, and the maintenance platform 5 is set on the lifting device, and the staff can stand on the maintenance platform Maintenance work is carried o...

Embodiment 2

[0069] An intelligent lifting platform for electric power maintenance. The lifting device includes a front lifting device and a rear lifting device. Both the front lifting device and the rear lifting device include two sets of lifting brackets connected end to end. Each set of lifting brackets includes two upper and lower layers in an X shape The scissor support of each layer of scissor support includes a first scissor arm 6 and a second scissor arm 7, and the two scissor arms are hinged at the center through a rotating pair;

[0070] The lower ends of the two scissor arms supported by the upper layer of scissors are respectively hinged with the upper ends of the two scissor arms supported by the lower layer of scissors.

[0071] The upper end of one scissor arm in the upper scissor support of the uppermost group of lifting brackets is connected to the lower plane of the maintenance platform 5 through the rotating pair and the moving pair, and the upper end of the other scissor...

Embodiment 3

[0078] A method for using an intelligent lifting platform for power maintenance, comprising the following steps:

[0079] a. Move the intelligent lifting platform for power maintenance through the walking wheels 10 at the bottom of the base 1 to reach the accident / maintenance site;

[0080] b. Start the support hydraulic cylinder 8 through the controller, open the support rod 9 and support it on the ground, so that the intelligent lifting platform for electric maintenance cannot move;

[0081] c. Start the accelerometer and gyroscope module, and transmit the inclination signal of the first-level lifting platform 3 measured by the accelerometer and gyroscope module to the controller, and the controller controls the actions of the four leveling hydraulic cylinders 2 to lift the first-level lift Platform 3 is adjusted to a horizontal position;

[0082] d. The controller controls the action of the lifting hydraulic cylinder 4, and the lifting device raises the maintenance platfor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com