Optical detection device and method for three-dimensional structure of micro-nano device

An optical detection, three-dimensional structure technology, applied in the direction of using optical devices, measuring devices, instruments, etc., can solve the problems of measuring the internal structure of the device, affecting the measurement speed, and slow measurement speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

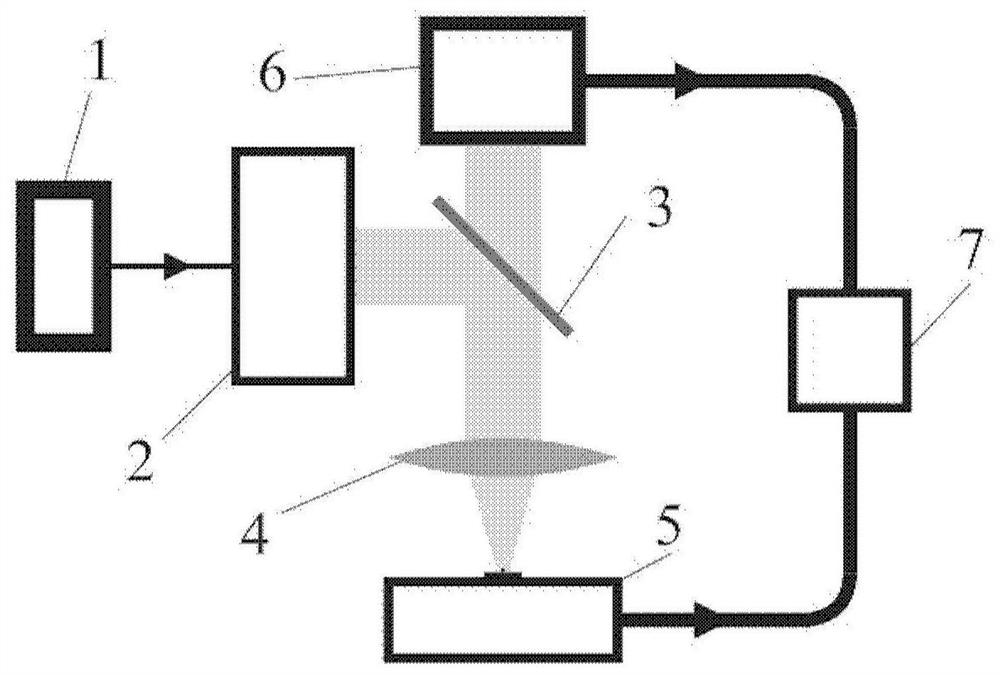

[0030] The invention irradiates the sample at the out-of-focus position with the converging light beam, and records the light intensity distribution of the reflected light field by the detector. The light beam sweeps across the sample to be tested horizontally at a certain step length. Since the sample is in a defocused position, the incident angles of different positions of the converging spot are different, and the impact of the sample to be tested on the reflected light field is also different. Therefore, the detector will record a series of slightly different reflected light field images, and select the data on the central axis of each image to form a new scanned composite image. At the same time, since the structural features and geometric parameters of the sample to be tested will affect the intensity distribution of the reflected light field, the structural features and geometric parameters of the sample to be tested can be obtained by comparing the measured scanned comp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com