A kind of preparation method of water-dispersed guar gum fracturing fluid crosslinking agent

A guar gum fracturing fluid and cross-linking agent technology, which is applied in the field of nanomaterials, can solve the problems of substandard properties such as residue content, complex synthesis industry, slow liquid preparation, etc., achieve effective and economical fracturing construction process, and simple preparation process , the effect of reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] A preparation method of a water-dispersed guar gum fracturing fluid cross-linking agent, comprising the following steps: adding 4 g of boric acid to 50 mL of glycerol, adding ammonia water to adjust the pH to 8, heating up to 40° C., stirring at a constant speed of 300 rpm for 0.5 h, adding boric acid Dissolve completely; raise the temperature to 60°C, add 14g of γ-aminoethylaminopropyltrimethoxysilane, stir at a constant speed of 200rpm for 4h, raise the temperature to 90°C, continue to stir for 1h, suction filter and dry to obtain solid guar gum fracturing fluid crosslinking agent.

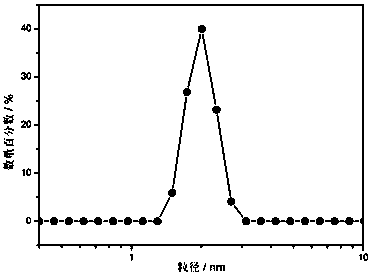

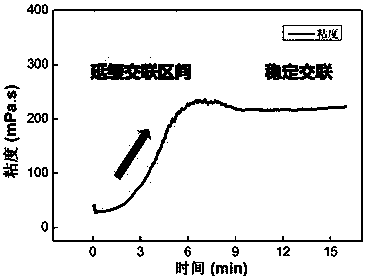

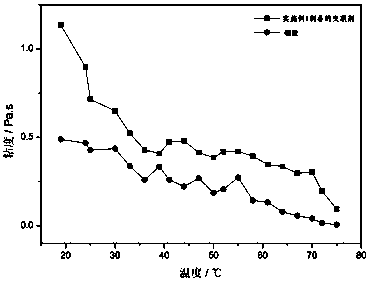

[0019] Such as figure 1 As shown, the particle size of the guar gum fracturing fluid crosslinking agent prepared above was measured by a laser particle size tester to be about 2 nanometers. The cross-linking agents prepared above were respectively configured into cross-linking solutions with mass fractions of 0.5%, 1%, 2% and 3%, and their light transmittances were 91.5%, 92.7%, 77.7% an...

Embodiment 2

[0023] A preparation method of a water-dispersed guar gum fracturing fluid cross-linking agent, comprising the following steps: adding 5 g of borax to 50 mL of formamide, adding sodium hydroxide solution to adjust the pH to 7, heating up to 40° C., and stirring at a constant speed of 300 rpm for 0.5 h Until the borax is completely dissolved; heat up to 60°C, slowly add 10g of γ-aminoethylaminopropyltrimethoxysilane dropwise, stir at a constant speed of 150rpm for 4h, and distill under reduced pressure to obtain an emulsion-like guar gum fracturing fluid crosslinking agent.

[0024] The particle size of the guar gum fracturing fluid crosslinking agent prepared above was measured by a laser particle size tester to be about 2 nanometers. The cross-linking agent prepared above was configured into a cross-linking liquid with a mass fraction of 1%, and a guar gum solution with a mass fraction of 0.3%. Take 2 ml of cross-linking solution and add it to 100 ml of guar gum solution with...

Embodiment 3

[0026] A preparation method of a water-dispersed guar gum fracturing fluid cross-linking agent, comprising the following steps: adding 4 g of boric acid to 20 mL of ethanol, adding ammonia water to adjust the pH to 8, raising the temperature to 40° C., and stirring at a constant speed of 300 rpm for 1 hour until the boric acid is completely dissolved; Raise the temperature to 60°C, add 4g of γ-(2,3-glycidoxy)propyltrimethoxysilane, stir at a constant speed of 200rpm for 4h, raise the temperature to 90°C, continue to stir for 1h, suction filter and dry to obtain solid guanidine Glue fracturing fluid crosslinking agent.

[0027] The particle size of the guar gum fracturing fluid crosslinking agent prepared above was measured by a laser particle size tester to be about 2 nanometers. The nano-crosslinking agent prepared above was configured into a crosslinking solution with a mass fraction of 1%, and a guar gum solution with a mass fraction of 0.3%. Take 2 ml of cross-linking sol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com