Embedded parts for steel plate-concrete structures

A technology of steel plate concrete and embedded parts, which is applied in the direction of building structure and construction, can solve problems such as mechanical properties and construction differences, no invention of embedded parts, specification requirements, structure and construction technology, difficulties, etc., to avoid On-site welding, avoiding the effect of additional positioning tooling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

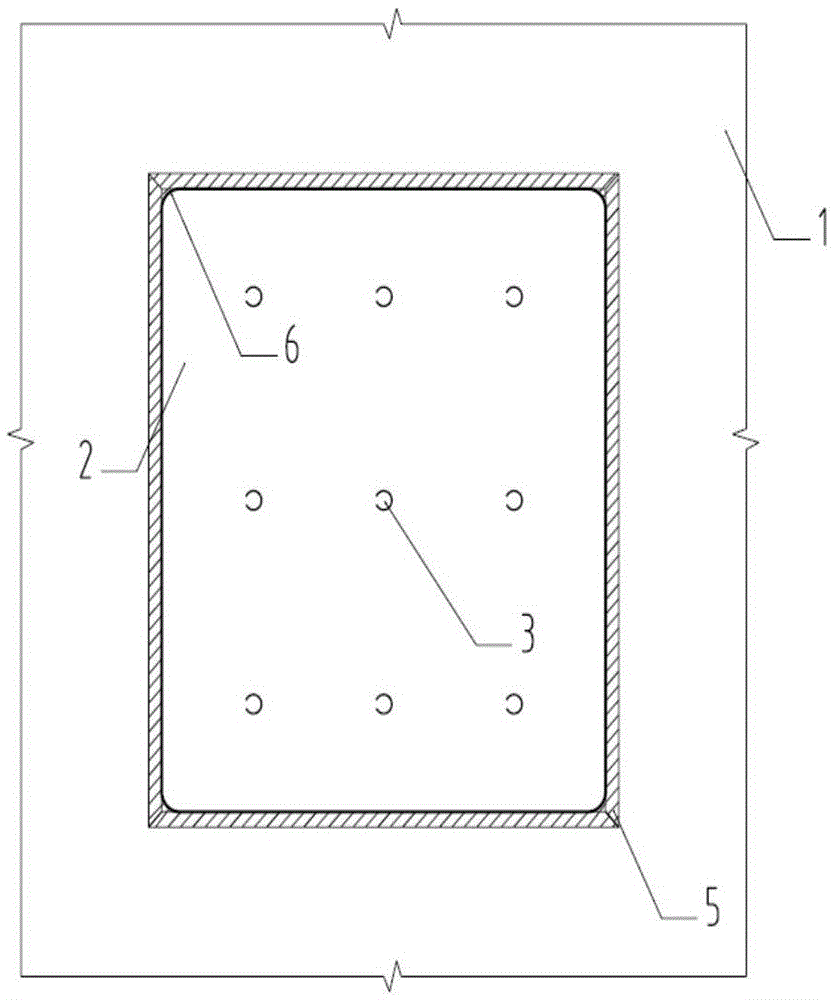

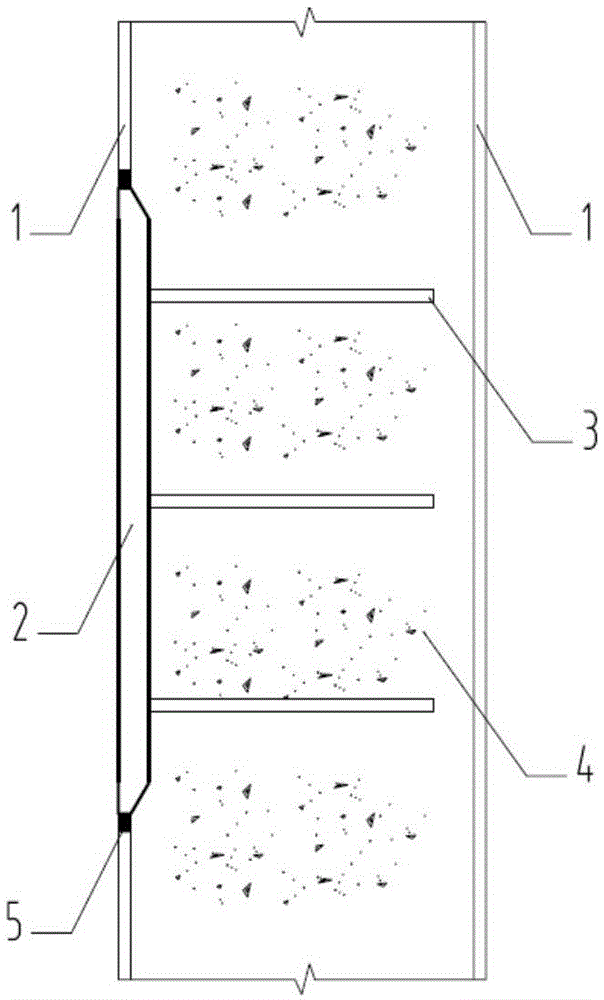

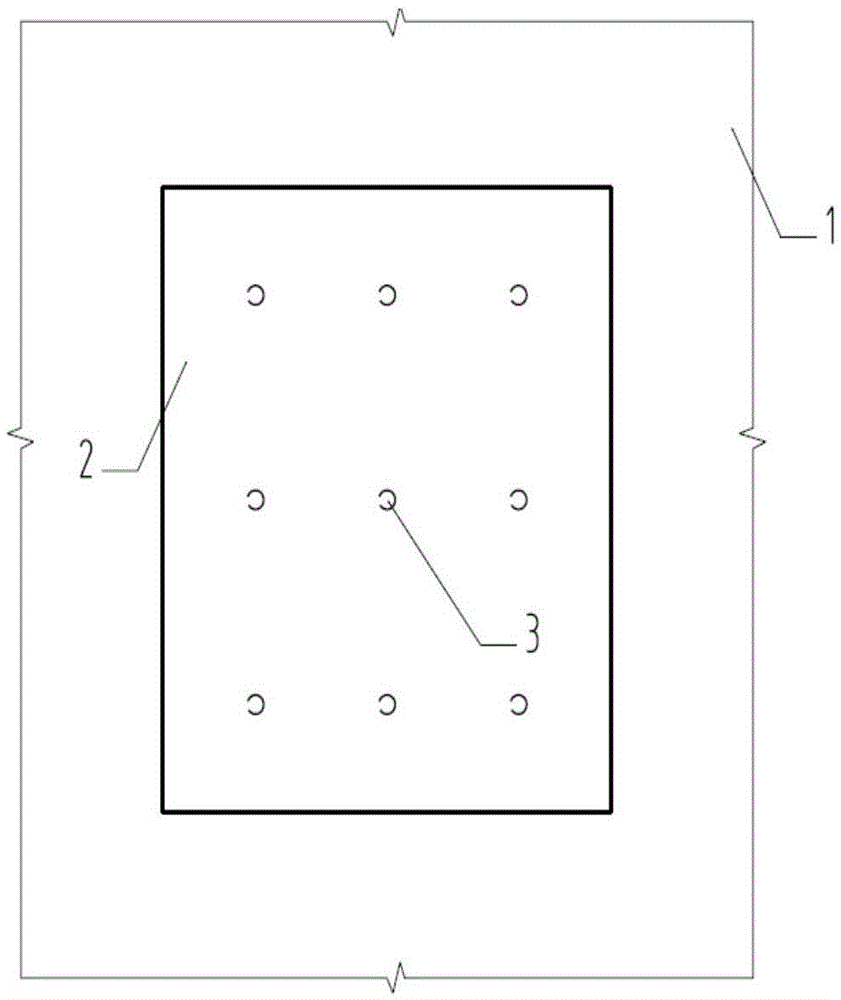

[0022] Attached below figure 1 , 2 The A-type embedded part of the present invention is further described with examples.

[0023] Step 1, prefabricating steel plate 1 of steel plate concrete in factory;

[0024] Step 2, prefabricate the steel panel 2 and the anchor bar 3 of the embedded part in the factory, fillet the four corners of the steel panel 2 with a radius of 25mm 6, and weld the steel panel 2 and the anchor bar 3 to complete the embedded part;

[0025] Step 3, when the difference in thickness between the steel plate 1 of the steel plate concrete and the steel panel 2 of the embedded part is more than 4mm, the edge of the steel panel is made with a bevel angle not greater than 1:2.5;

[0026] Step 4, after determining the position of the steel panel 2 of the embedded part on the steel plate 1 of the steel plate concrete, opening holes on the steel plate 1 to install the embedded part, and connecting the steel plate 1 and the steel panel 2 into a whole through the bu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com