The structure of the vehicle turn signal

A technology of vehicle orientation and structure, applied in the direction of headlights, road vehicles, vehicle parts, etc., can solve the problems of different cooling rates, affecting the aesthetics of the lampshade 12, and dent deformation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

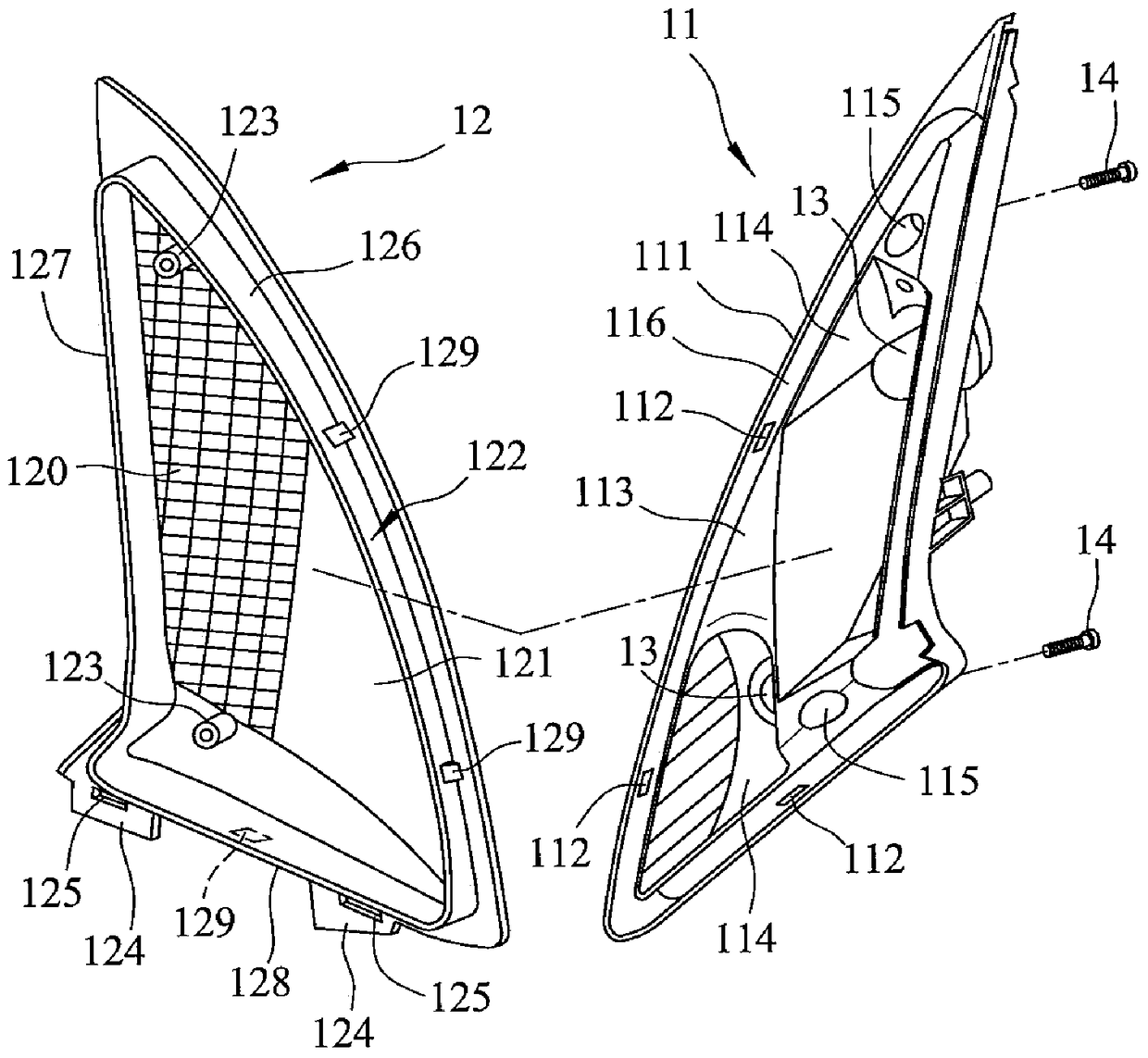

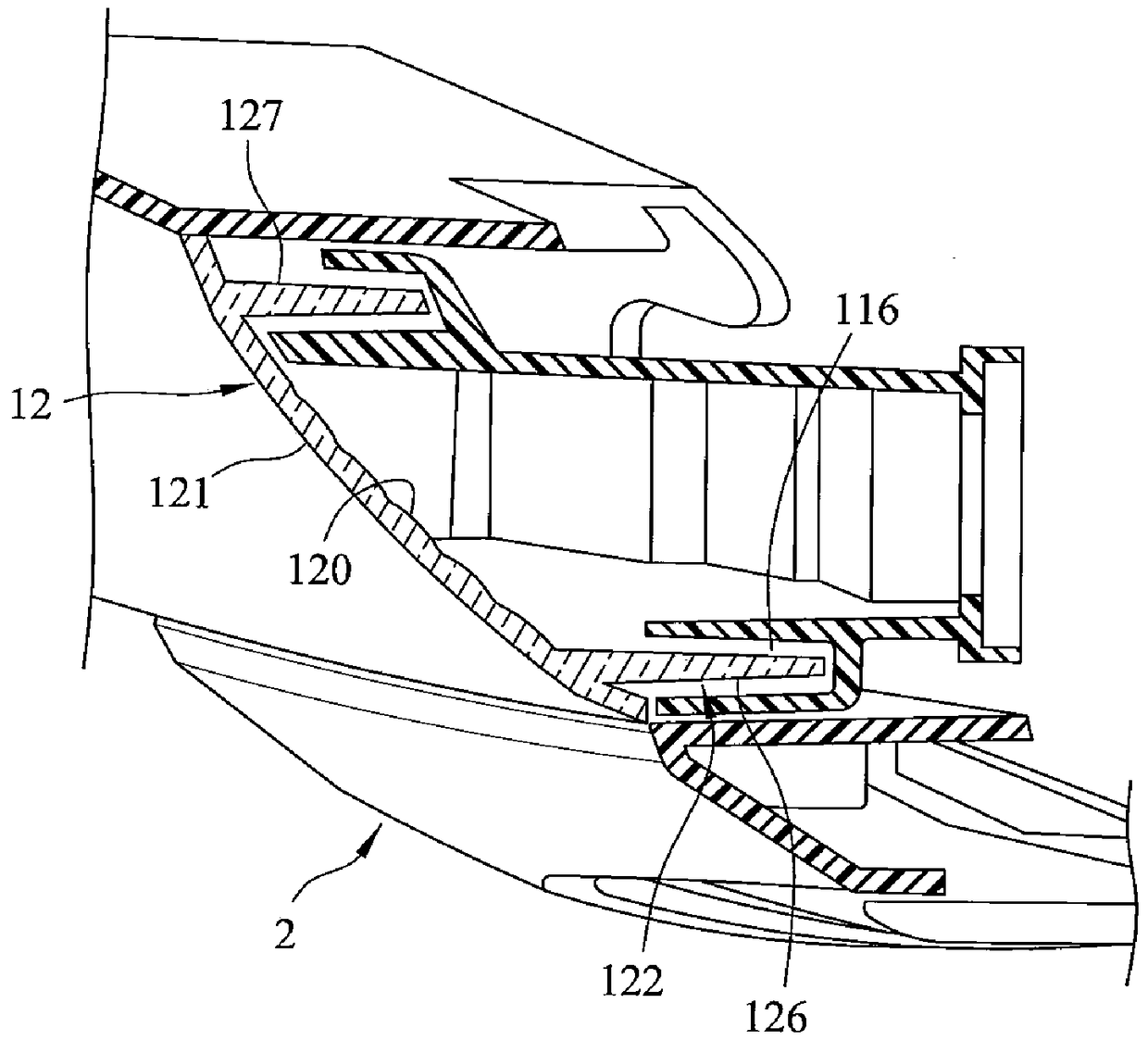

[0019] refer to Figure 4 , 5 , 6, is an embodiment of the structure (structure) of the vehicle direction light of the present invention, including a lamp holder 3 , a lampshade unit 4 , and a light emitting unit 5 .

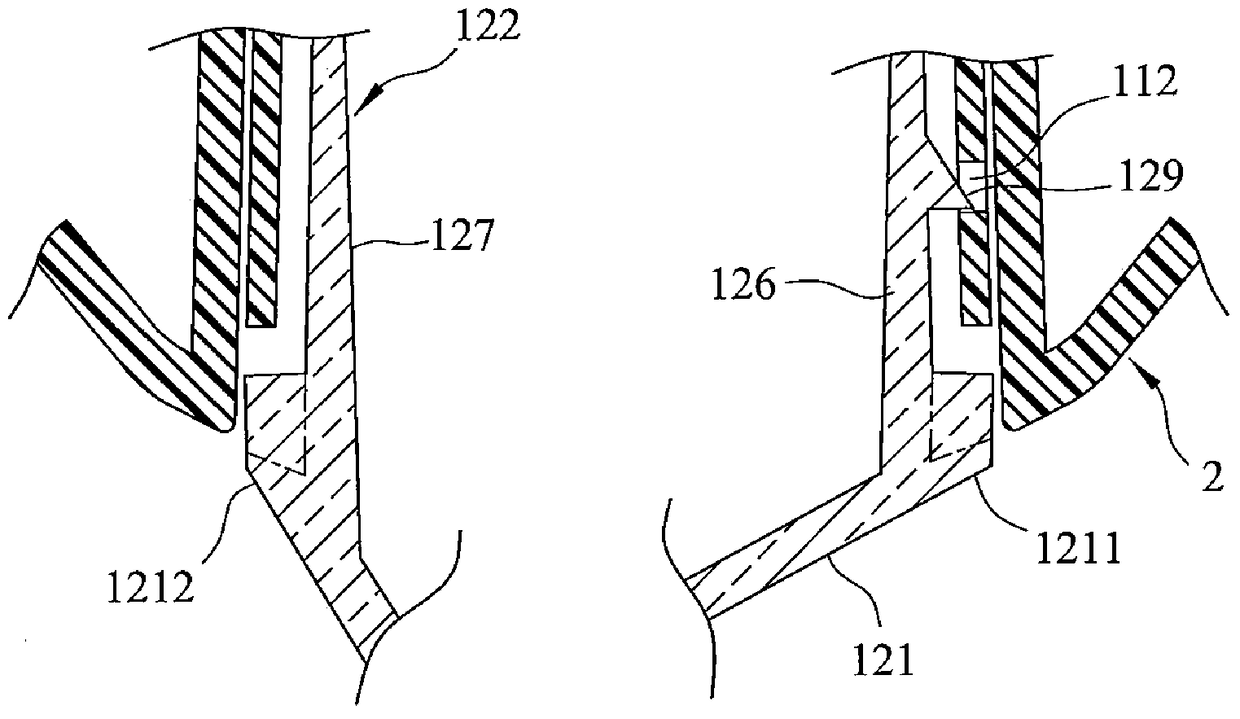

[0020] The lamp holder 3 has a first inner extension section 31 and two first outer extension sections 32, the first inner extension section 31 and the first outer extension section 32 are connected around each other and jointly define a circle for use. A carrying space 33 for accommodating the light emitting unit 5 . In addition, the lamp holder 3 also has a peripheral wall 34 , an inner peripheral wall 35 protruding from the carrying space 33 and spaced from the peripheral wall 34 , and an end connecting the peripheral wall 34 and the inner peripheral wall 35 . The connecting wall 36 , the peripheral wall 34 , the inner peripheral wall 35 and the connecting wall 36 jointly define an accommodating groove 37 . The portion of the peripheral wall 34 correspondi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com