Drainage and drag reduction device in the guide tube, guide tube and shell-and-tube heat exchanger

A technology of drag reduction device and guide tube, applied in the direction of heat exchanger type, heat exchanger shell, indirect heat exchanger, etc., can solve the problem of reduced pressure bearing capacity of heat exchanger shell side and unreasonable design of guide tube structure , the complex structure of the guide tube, etc., to achieve the effect of eliminating the stagnation area, simple structure and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

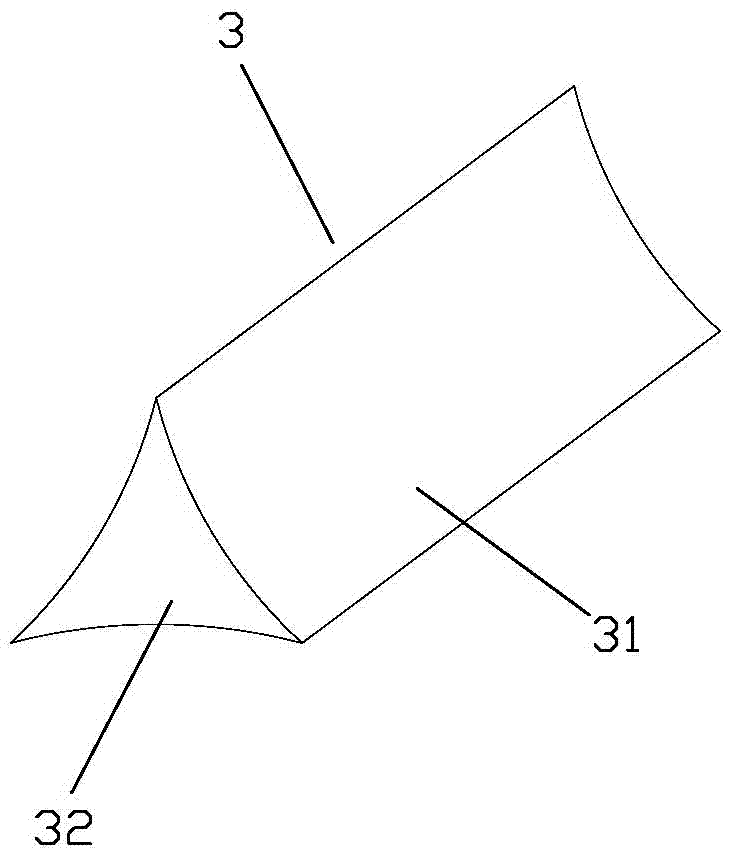

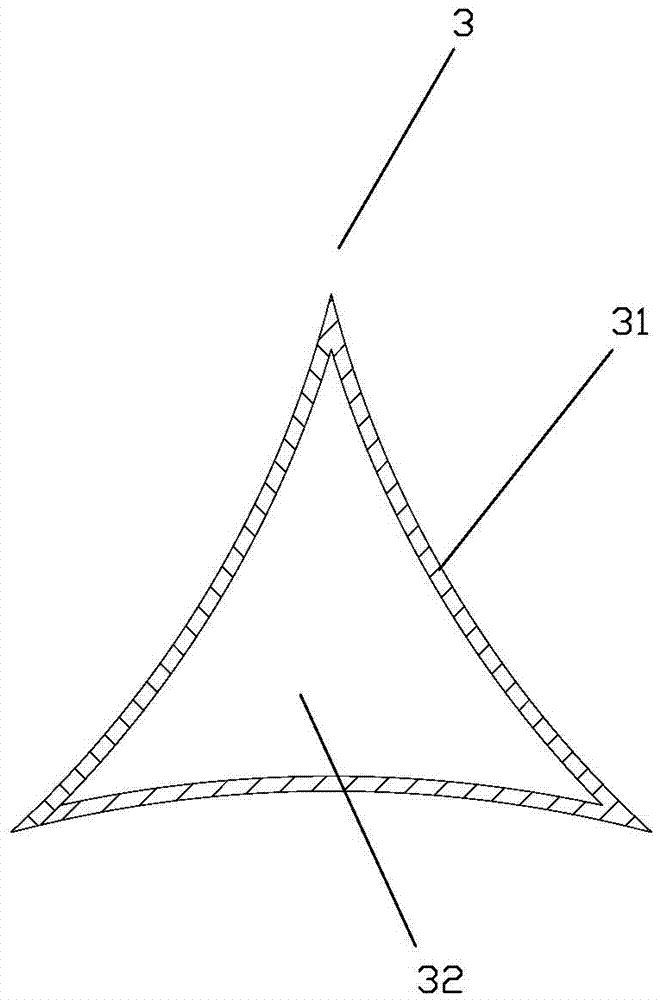

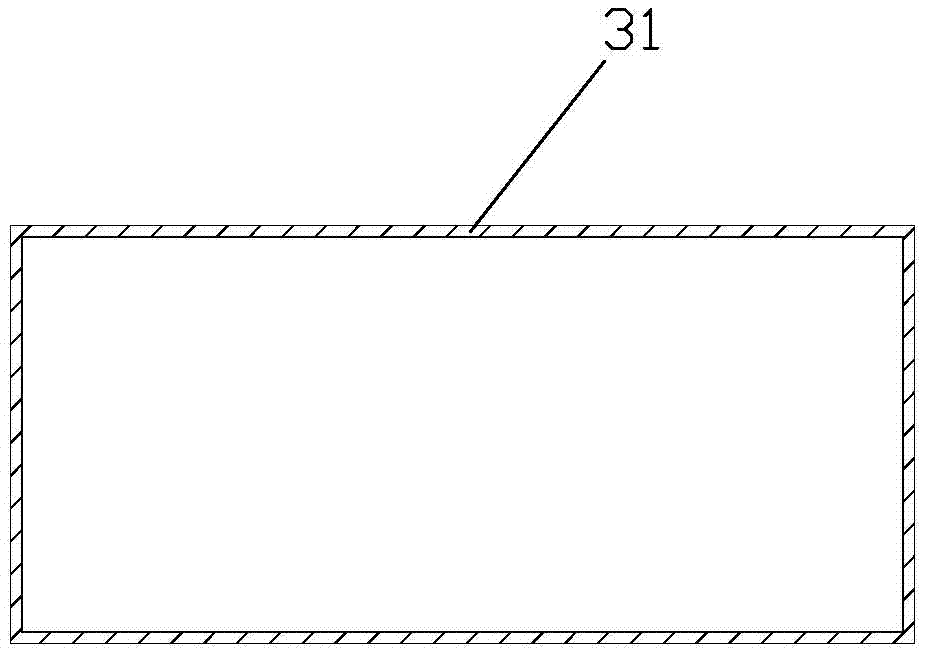

[0034] The guide tube of this embodiment is as Figure 1 to Figure 5 As shown, the guide tube 2 includes a guide tube inner shell 21 and a guide tube outer shell 22, the guide tube shell 22 is provided with a shell-side inlet 23, and the guide tube 2 is provided with a drainage drag reducing device 3, and the drainage drag reducing device 3 is arranged along the axial direction of the inner shell 21 of the guide tube, and the drainage and drag reduction device 3 is a closed structure formed by splicing two arc-shaped plates 31 and two side plates 32 . Among them: the two arc-shaped plates 31 and the two side plates 32 are symmetrically arranged, the upper ends of the two arc-shaped plates 31 are welded, the lower ends of the two arc-shaped plates 31 are respectively welded to the inner shell 21 of the guide tube, and the two arc-shaped plates The opposite side ends of the plate 31 are respectively welded to the corresponding side plates 32, and the arc surfaces of the two arc ...

Embodiment 2

[0042] The shell-and-tube heat exchanger of the present embodiment, such as Figure 4 and Figure 5 As shown, including the housing 1, the inlet 11 and the outlet 12 of the housing 1 are provided with a guide tube 2, and the guide tube 2 at the inlet 11 of the housing 1 is provided with a drainage and drag reduction device 3. The structure of the drainage drag reducing device 3 is exactly the same as that of the first embodiment.

[0043]When the fluid enters the guide tube 2, the fluid flows to both sides through the two arc-shaped plates 31, and its scour resistance is dispersed, so that the fluid distribution is uniform and the vertical scour is reduced, so that the irregular fluid changes after entering the guide tube 2 Forming a regular fluid can stabilize the flow field and reduce fluid flow resistance, and avoid the huge fluid resistance borne by the guide tube 2, reducing the impact of the fluid on the heat exchange tube 4; on the other hand, this The invention can e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com