Testing method for friction loss and anchorage loss of post-tensioned prestressed concrete structures

A concrete structure, post-tensioning prestressing technology, applied in the direction of measuring devices, material inspection products, instruments, etc., can solve the problems of inaccurate sensor display, poor sensor alignment, eccentric compression, and failure to measure prestress friction loss. , to achieve high detection accuracy and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

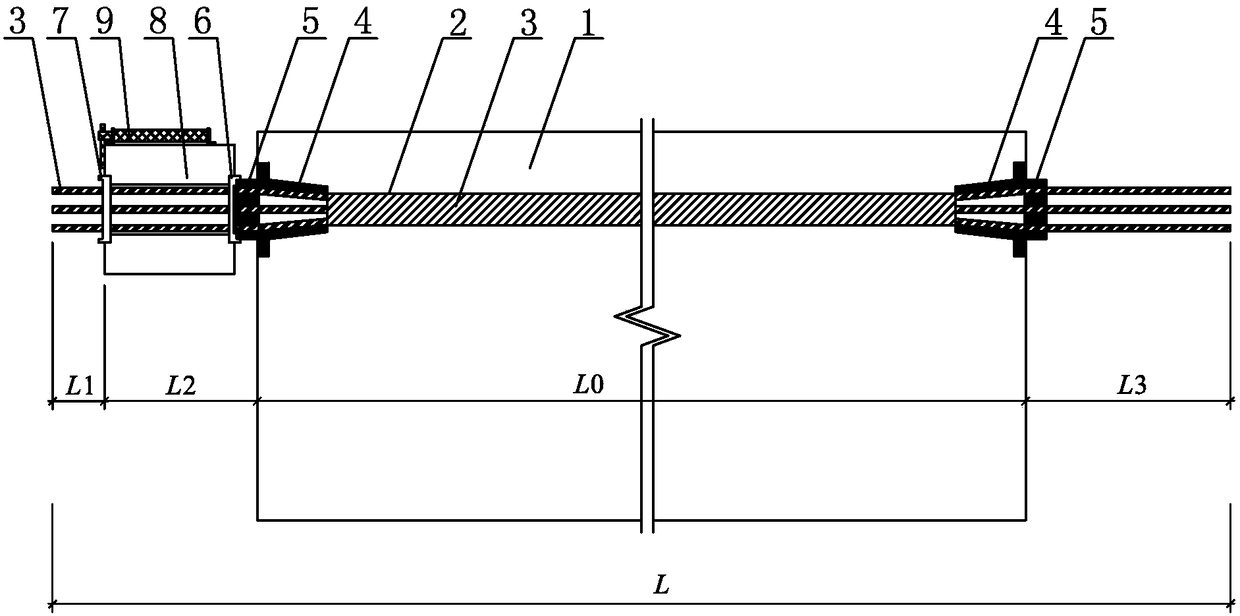

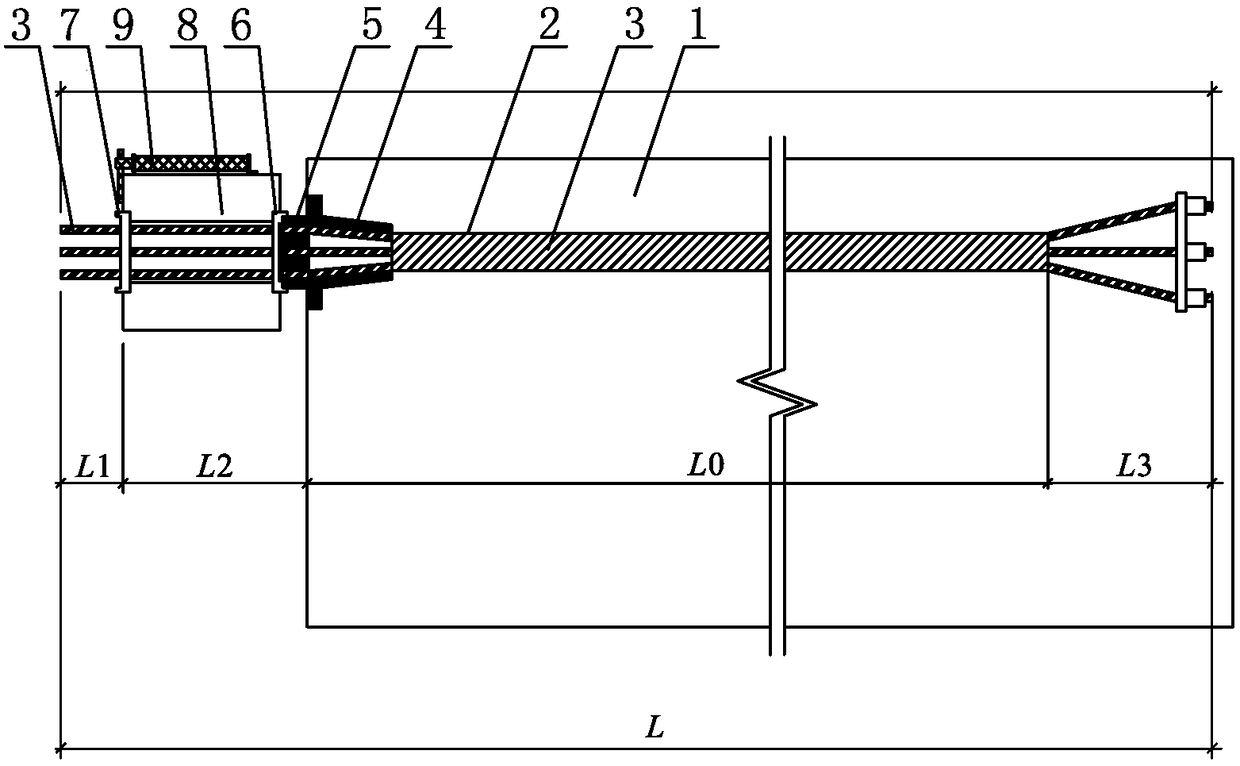

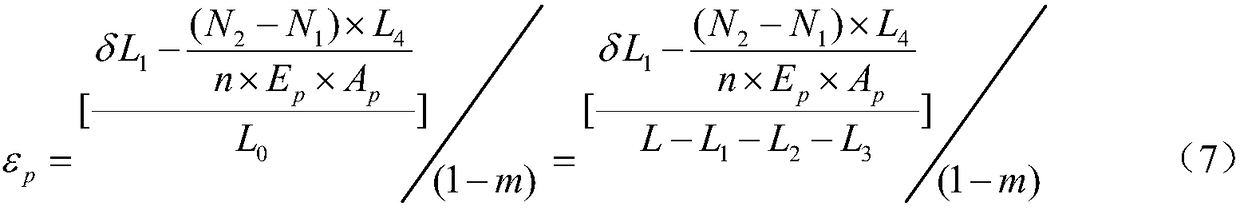

[0054] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

[0055] This part takes a 25.7-meter-span prestressed beam as an example to detect the friction loss and anchorage loss under the tension construction technology at both ends.

[0056] The design parameters of the prestressed beam are as follows:

[0057] ① Bonded prestressed beam, concrete strength C40, reinforcement 2-9Φ s 15.2, using f ptk = 1860MPa low-relaxation steel strands, metal bellows with a wall thickness of not less than 0.3mm, and group anchor systems for anchorage.

[0058] ②The axis span of the prestressed beam is 25.7 meters. At the column, the straight line section at the fixed end is 0.5m, the straight line section at the tension end is 0.3m, the left sagittal height is 1500mm, and the right sagittal height is 1200mm. The tension control stress σ con =0.7f ptk =0.7×1860=1302Mpa, the design overtension coefficient is 3%, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com