Remote monitoring system of special-shaped pipe steel reinforcement framework seam welder and monitoring method thereof

A technology of remote monitoring system and steel frame, applied in the transmission system, closed-circuit television system, electrical components, etc., can solve the problems of high cost of after-sales service, low efficiency, seam welding machine manufacturers do not understand the operation status of the seam welding machine, etc. Achieve the effect of reducing the cost of after-sales service, improving timeliness and avoiding winding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with specific drawings and embodiments.

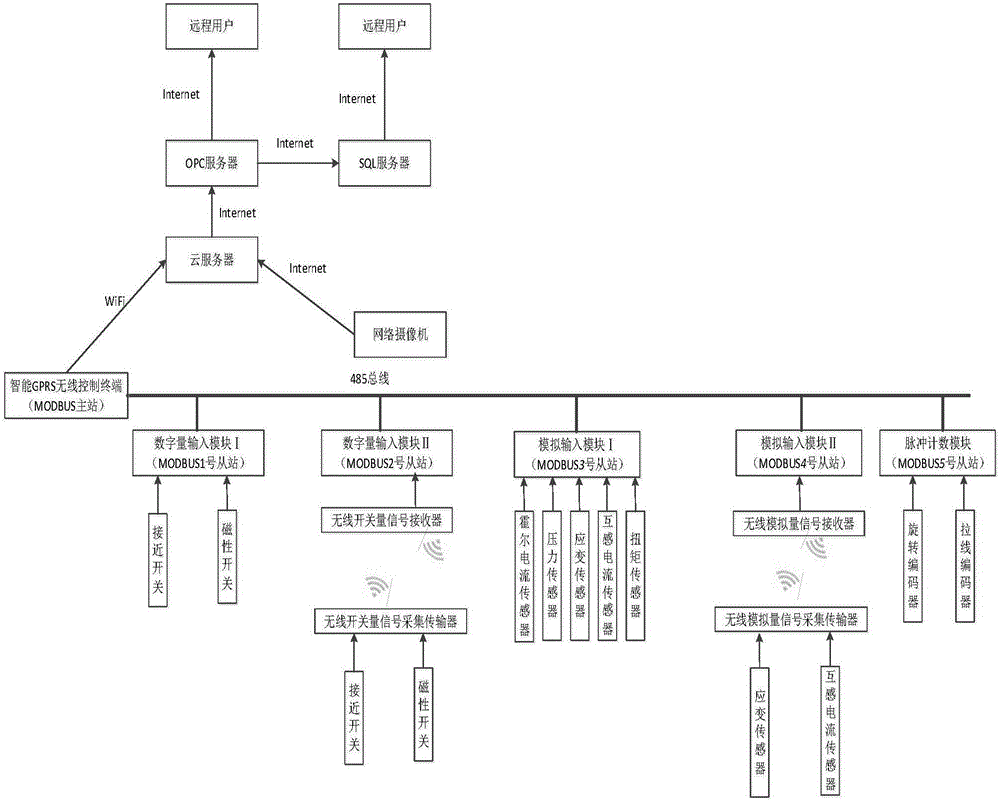

[0031] A remote monitoring system for special-shaped steel bar frame seam welding machine, the system includes: OPC server, SQL server, intelligent GPRS wireless control terminal, digital input module I, digital input module II, analog input module I, analog input Module II, pulse counting module and network camera. Due to the complex structure of the special-shaped pipe steel bar frame seam welding machine, there are many signals that need remote monitoring, and the distance between each monitoring point is long. Here, a MODBUS network is constructed, and the intelligent GPRS wireless control terminal is used as the MODBUS master station. The above-mentioned digital input module I, digital input module II, analog input module I, analog input module II, and pulse counting module are used as MODBUS slave stations to form a MODBUS network. MODBUS slave stations a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com