High pressure water mist fire extinguishing nozzle

A technology of high-pressure water mist and fire-extinguishing nozzles, which is used in fire rescue and other directions to achieve rapid fire-extinguishing, simple structure and less destructive effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

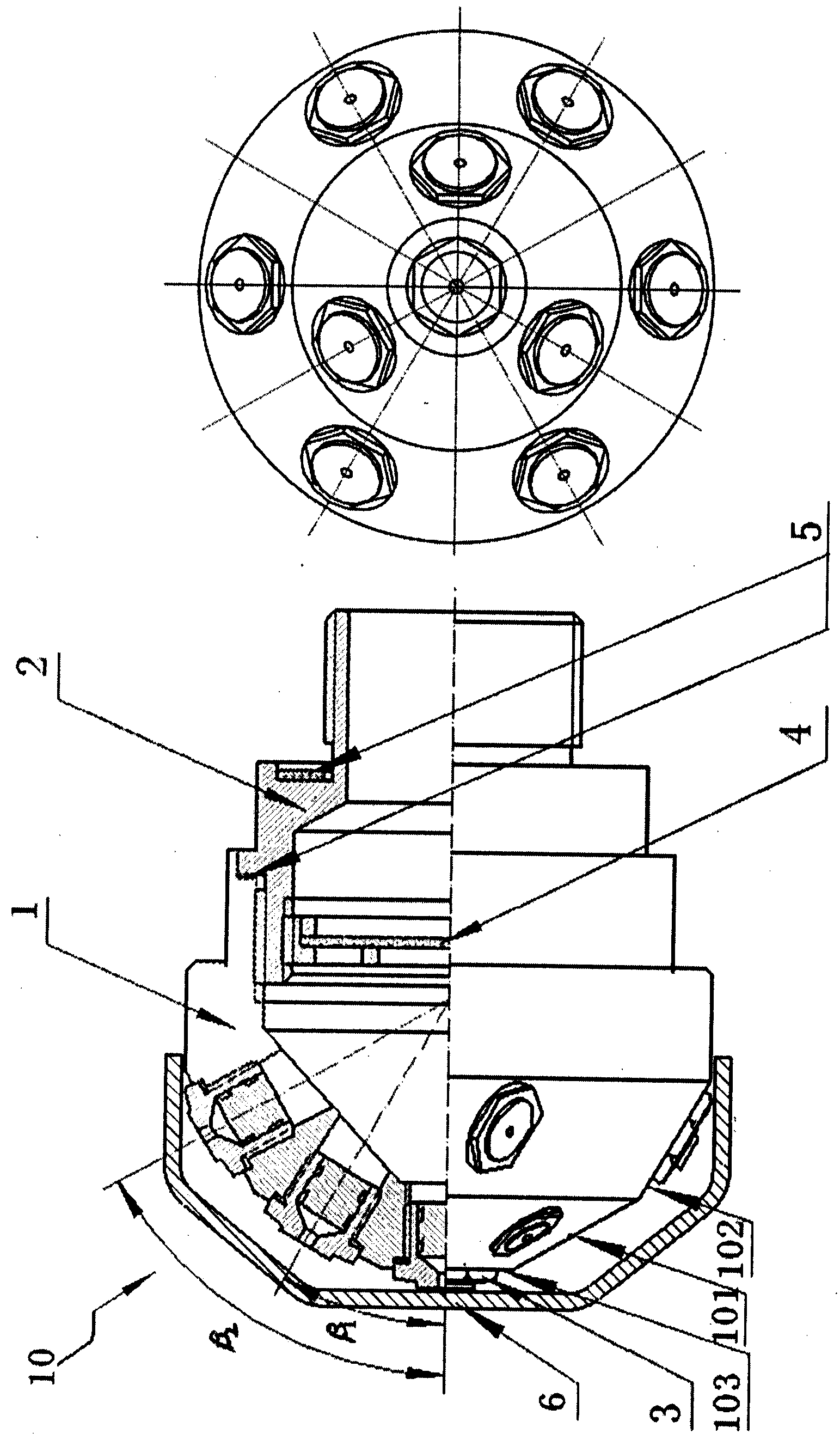

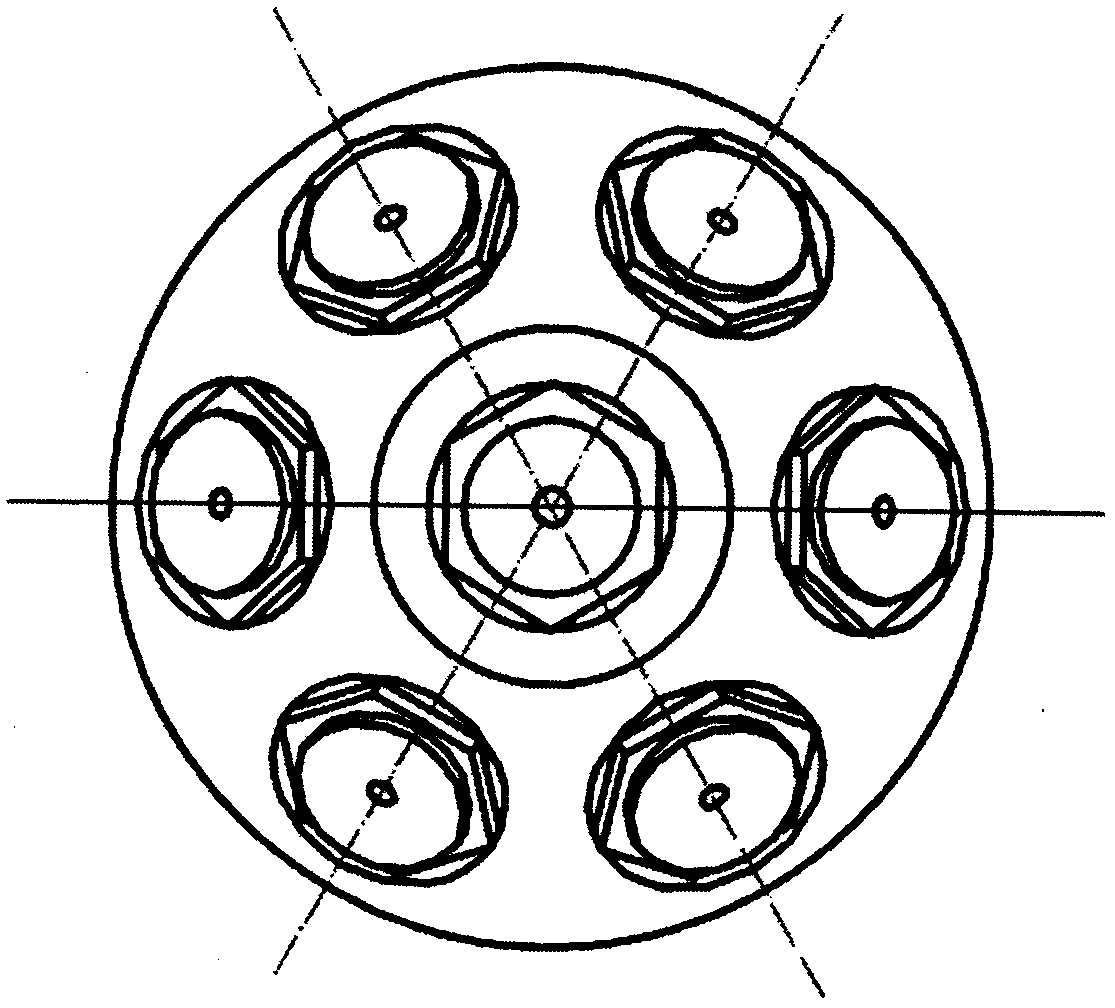

[0034] Such as figure 1 , figure 2 As shown, a high-pressure water mist fire extinguishing nozzle 10 (abbreviation: nozzle) of the present invention is mainly composed of a nozzle housing 1, a nozzle adapter 2, a nozzle 3, an internal filter 4, a metal sealing gasket 5 and a dust cover 6. . The profile of the nozzle housing 1 is two conical surfaces 101, 102, the top surface 103 of the conical surface 101 is a plane, and a nozzle 3 is installed at the center of the top surface 103, and the normal line of the conical surface 101 is clamped with the axis of the nozzle 10. The angle is 25 degrees; 3 nozzles 3 are evenly distributed on the conical surface 101, and these nozzles 3 choose a spiral groove structure, such as Figure 8 As shown, the swirl plate structure can also be selected, such as Figure 10 Shown; The spray angle of nozzle 3 is selected as 30 degrees, and the normal line of the outer ring conical surface 102 near the top surface conical surface 101 and the axis...

Embodiment 2

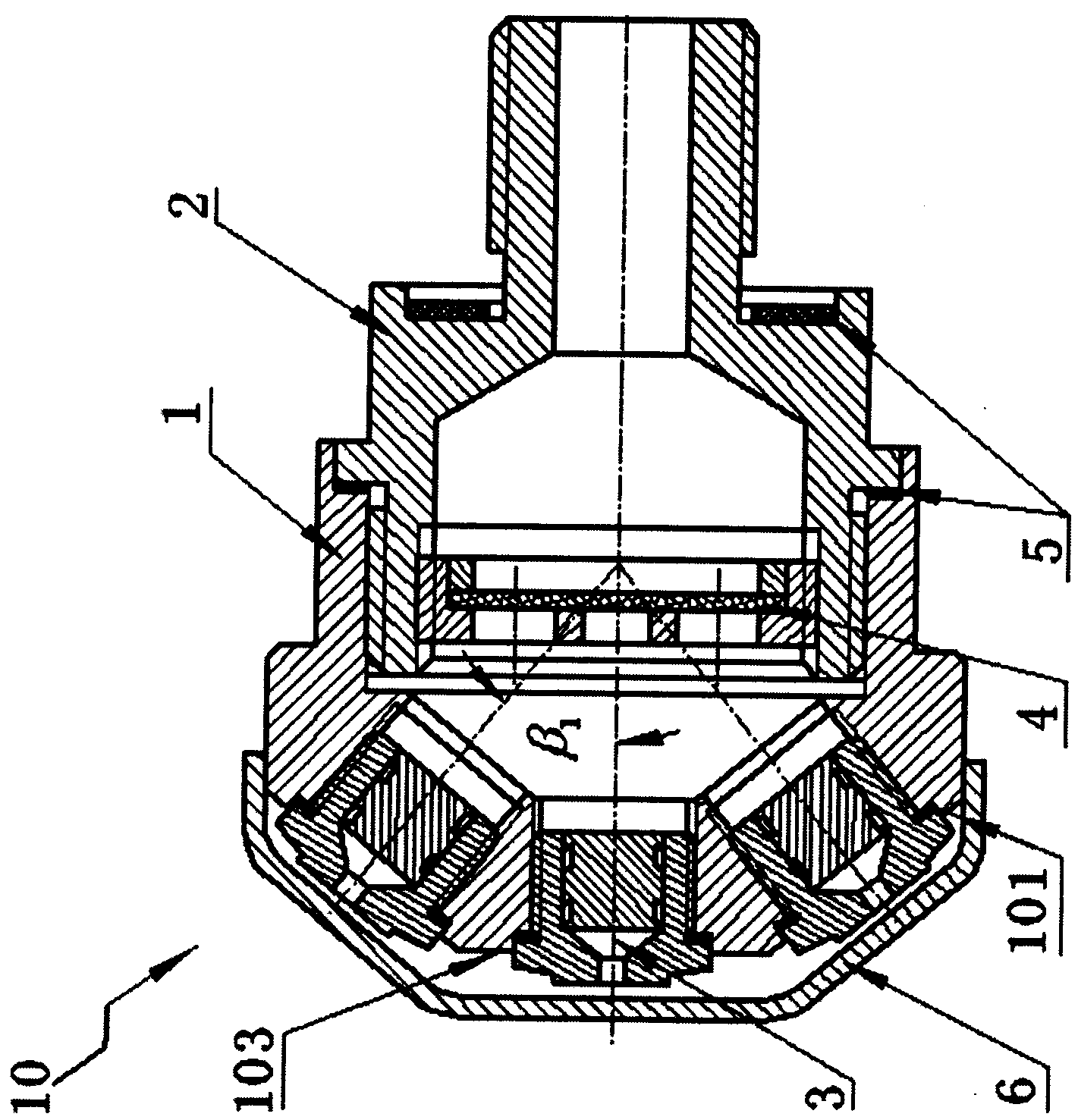

[0039] A second embodiment of a high-pressure water mist fire extinguishing nozzle 10 of the present invention is as follows image 3 , Figure 4 As shown, compared with the first embodiment, the difference is that the nozzle housing 1 of the second embodiment is designed as a conical surface 101, the top surface 103 of the conical surface 101 is a plane, and the center of the top surface 103 is installed There is one nozzle 3, and the angle between the normal line of the conical surface 101 and the axis of the nozzle 10 is 39 degrees; 6 nozzles 3 (or multiple nozzles) are evenly distributed on the conical surface 101; other shapes and structures And requirements are all the same as the foregoing embodiment one.

Embodiment 3

[0041] Embodiment three of the present invention is as image 3 , Figure 4 As shown, compared with Embodiment 1, the difference is that the nozzle housing 1 of Embodiment 3 is designed as a conical surface 101, the top surface 103 of the conical surface 101 is a plane, and the center of the top surface 103 is installed There are 3 nozzles 3; the angle between the normal of the conical surface 101 and the axis of the nozzle 10 is 39 degrees; 6 nozzles 3 (or multiple nozzles) are evenly distributed on the conical surface 101; other shapes and structures And requirements are all the same as the foregoing embodiment one.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com