A wire rope driven deployment sleeve

A technology of wire rope and traction wire rope, which is applied to the power supply system, folding antenna, and retractable unit of space navigation vehicle, etc., can solve the problems of large difference in outer diameter, unsuitable for one-dimensional expansion of slender rods, and inability to fold up, etc. The effect of stabilizing the movement resistance characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described in detail below in conjunction with the drawings and specific embodiments:

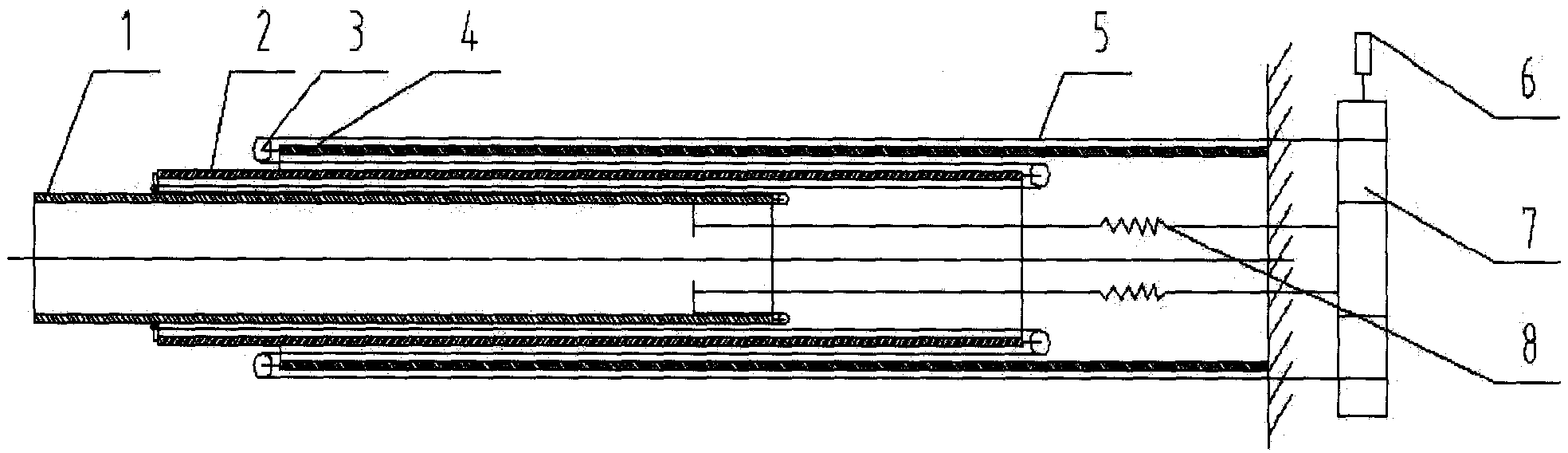

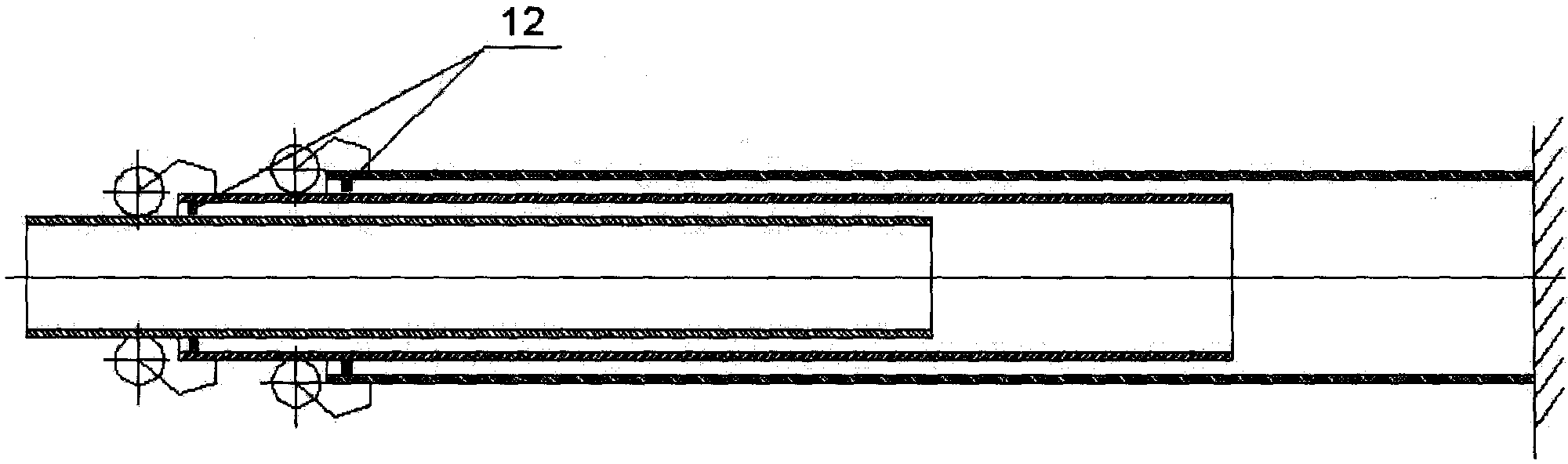

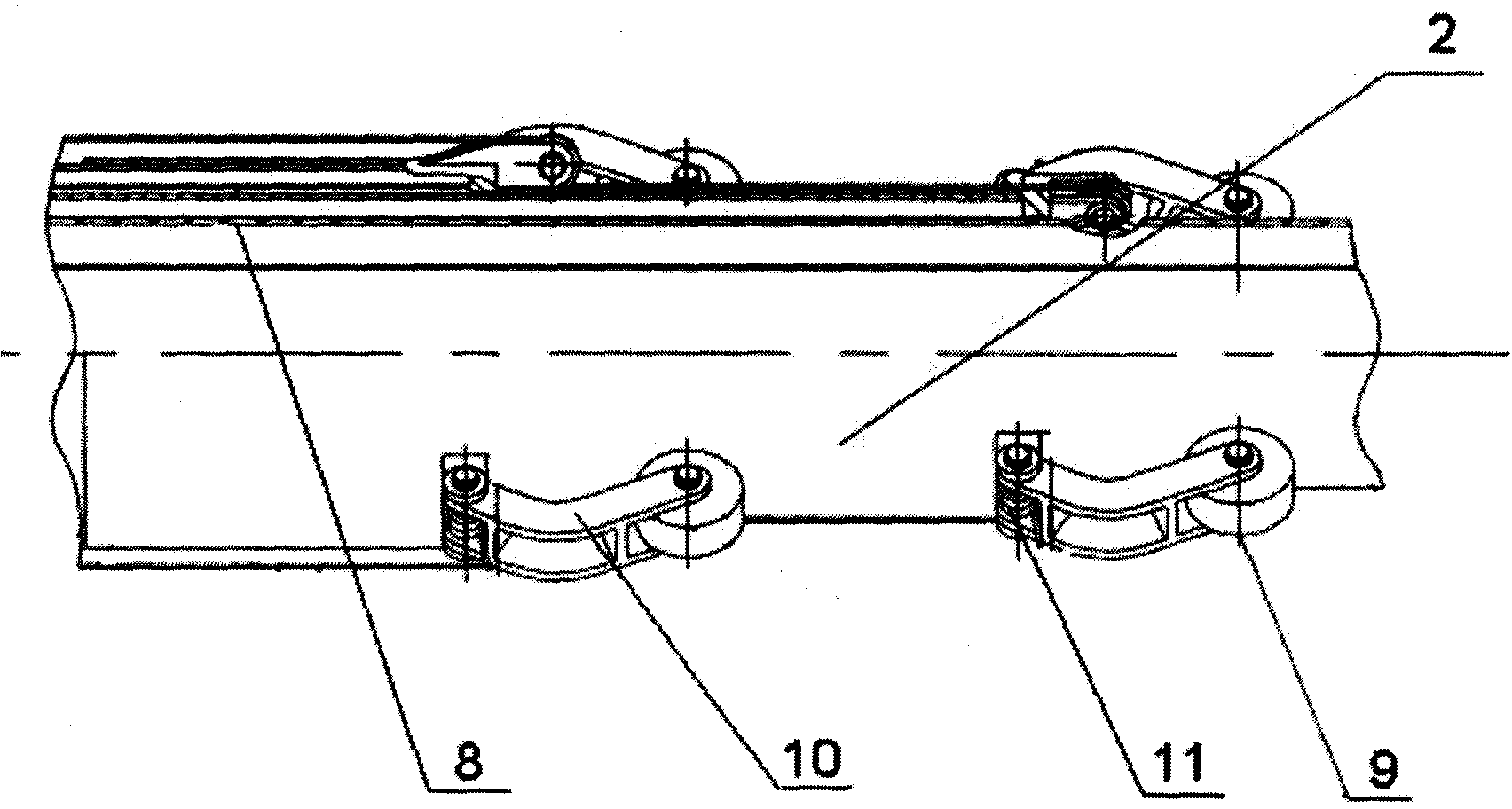

[0013] Such as figure 1 , 2 As shown in 3, the unfolding sleeve driven by the wire rope is composed of a driving part, a retractable part, a guide assembly and a locking assembly. The driving part is composed of a motor 6, a drum 7, a traction wire rope 5, a recovery wire rope 8, and a pulley 3; retractable parts It consists of three parts, namely the root sleeve 4, the middle sleeve 2 and the end sleeve 1. The guide assembly consists of the guide wheel 9, the guide wheel bracket 10 and the torsion spring 11; the locking assembly 12 is composed of a locking mechanism and a locking sensor. The end sleeve 1 is sleeved in the middle sleeve 2, and the middle sleeve 2 is sleeved in the root sleeve 4. The bottom end of the end sleeve 1, the two ends of the middle sleeve 2, and the top end of the root sleeve 4 are all installed Two sets of pulleys 3, one en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com