Vacuum frying pot

A technology for vacuum frying tanks and tanks, applied in oil/fat baking, loading/unloading of ovens, etc., can solve the problems of low automation efficiency, high cost of use, and much oil accumulation at the bottom of the tank, and achieve high automation efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

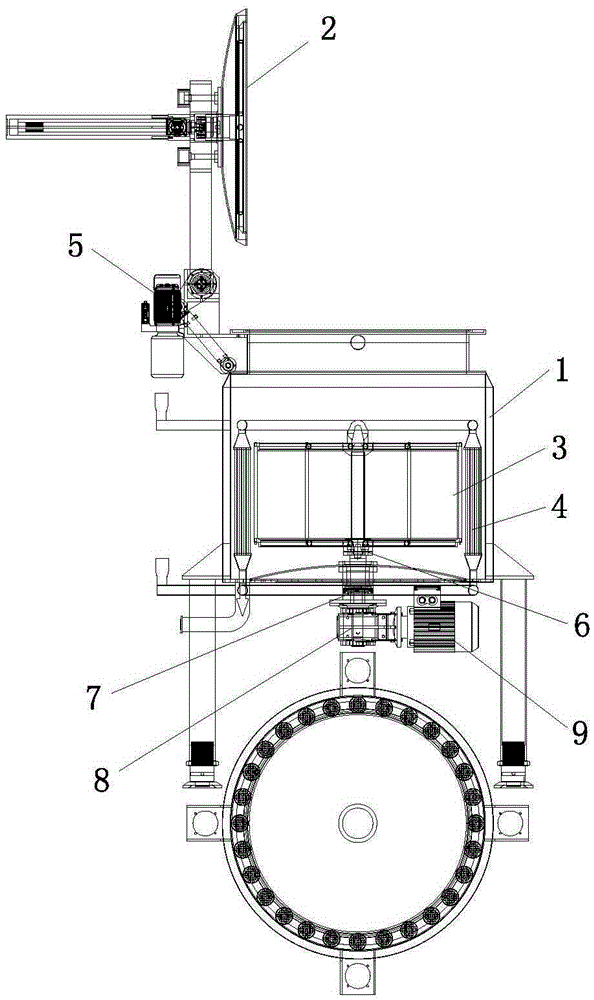

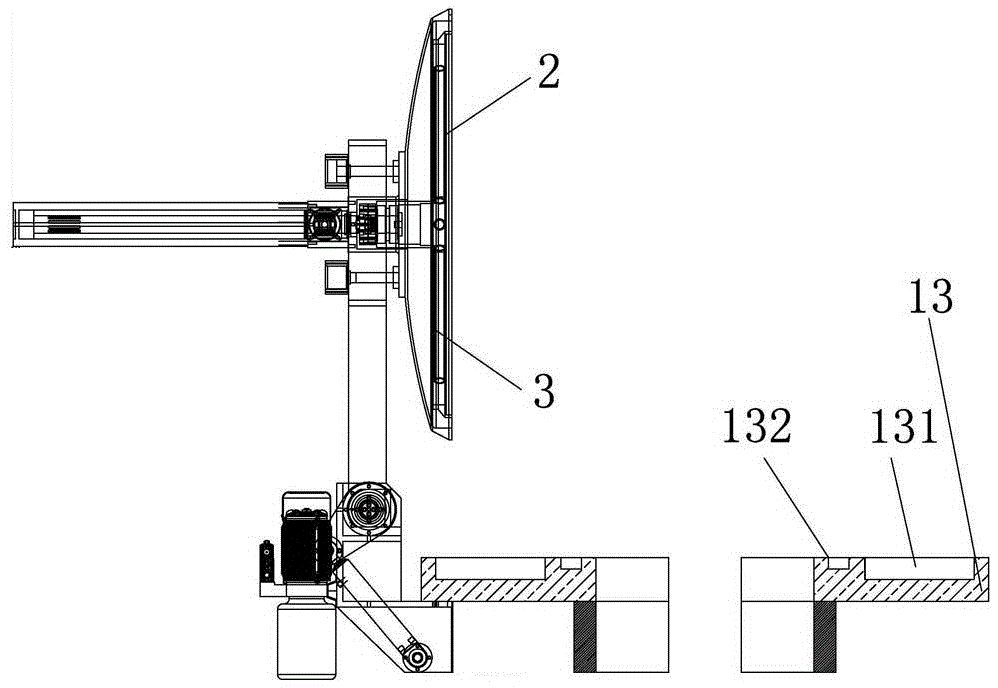

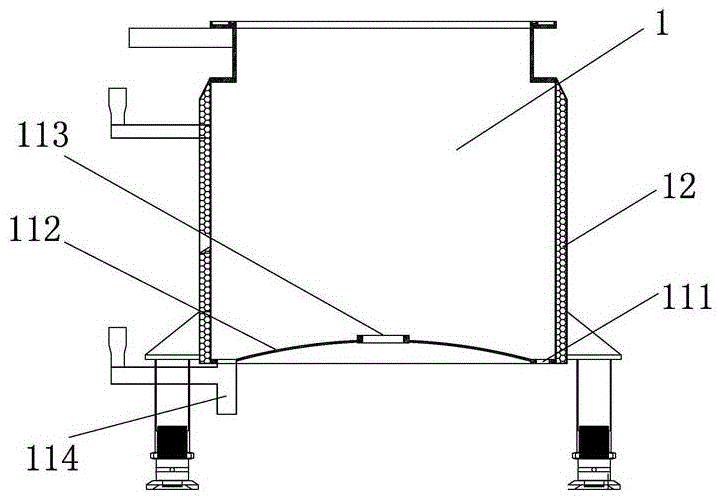

[0030] A vacuum frying tank of the present invention is composed of a tank body 1 , a tank cover 2 , a basket device 3 , a heating device 4 , an opening device 5 , a clutch 6 , a shaft coupling 7 , a reducer 8 , a motor 9 and a bracket 10 . The motor 9 and the reducer 8 are arranged under the bottom of the tank body 1 , and the motor 9 drives the material basket through the reducer 8 and the coupler 7 . The clutch 6 is composed of a guide shaft 61 and a shaft sleeve 62 , and the speed reducer 8 is fixedly connected with the guide shaft 61 of the clutch 6 .

[0031] The material basket 31 is arranged in the tank body 1, and the material basket 31 is composed of a lifting hook ear 311, an upper flange 312, a lower flange 313, a punching bottom plate 314, a punching side plate 315, and a flange fixing rod 316 , the upper and lower ends of the shaft sleeve 62 are fixed with an upper flange 312 and a lower flange 313, the lower flange is provided with a punching bottom plate 314, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com