Micro friction stir welding method for small-thickness component and stir shaft shoulder of micro friction stir welding method

A technology of micro-stirring and friction welding, which is applied in the field of stirring shaft shoulder and micro-stirring friction welding, can solve the problems of complex stability equipment, etc., and achieve the effect of ensuring the overall weld quality, increasing stability and reducing complexity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

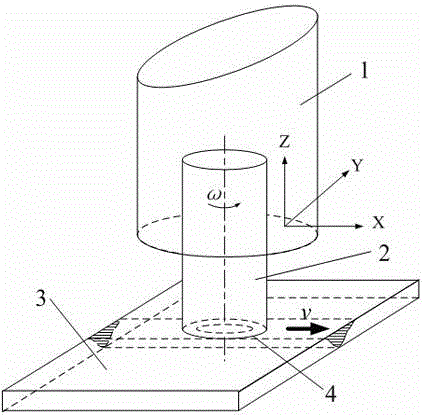

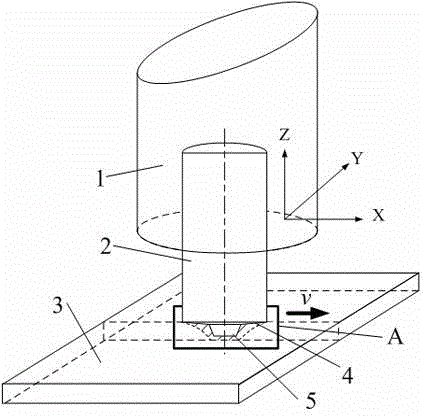

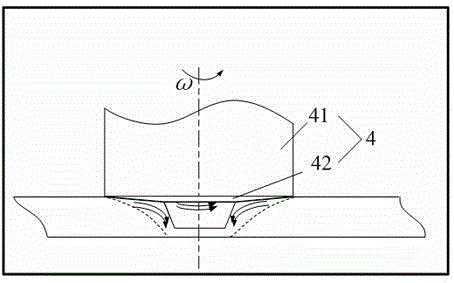

[0022] In order to describe the technical content, structural features, achieved goals and effects of the present invention in detail, the following will be described in detail in conjunction with the embodiments and accompanying drawings.

[0023] see figure 1 , the first embodiment of the micro-friction stir welding method for components with small thickness dimensions in the present invention is to weld the base material 3 to be welded (the base material to be welded is an ultra-thin aluminum alloy 6061 plate with a thickness of 0.8mm), including installing on the equipment spindle 1 A micro-stir friction welding tool 2 with a stirring shoulder 4, the stirring shoulder 4 is a flat shoulder with a cohesive pattern; during welding, the inclination angle between the equipment main shaft 1 and the normal direction of the workpiece surface is 0 degrees, and the equipment main shaft 1 drives the micro The friction stir welding tool 2 rotates at a rotation speed of at least 20000r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com