Electromagnetic punching machine

A stamping machine and electromagnetic technology, which is applied in the field of electromagnetic stamping machines, can solve the problems of long production cycle, inflexible use, and many stamping machine parts, and achieve the effects of easy control, simple structure, and light weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention.

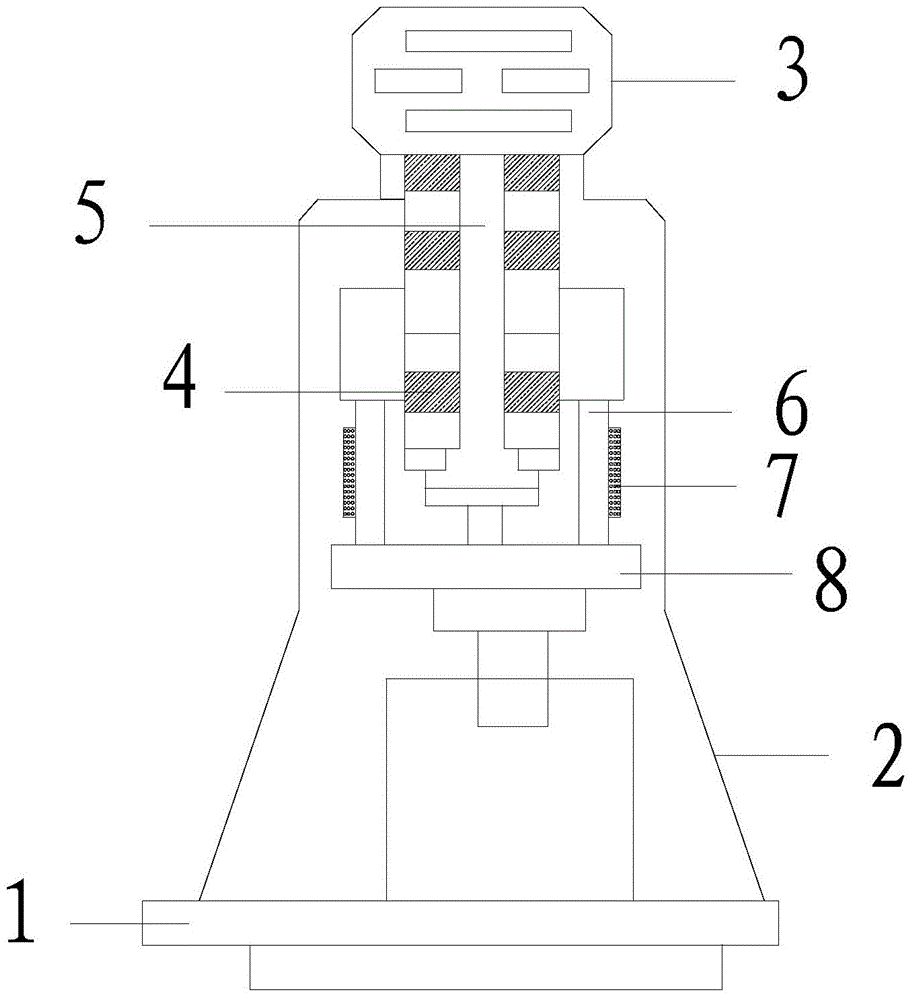

[0011] Such as figure 1 As shown, an electromagnetic stamping machine includes a workbench 1 and a body 2 arranged above the workbench 1. The body 2 is provided with a control system 3 and a linear motor in sequence. The linear motor includes a motor primary 4 and a motor secondary 5. Both sides of the motor are provided with a guide post 6 equipped with balls 7; a mold frame 8 is provided under the motor; the guide post 6 and balls 7 can ensure stamping accuracy during actual operation.

[0012] During actual implementation, plug in the power supply, start the power switch, and set the stamping tonnage. If it is automatic stamping, it is necessary to set the stamping operation frequency, and then start the stamping button, otherwise it is processed manually. When the button...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com