Disc-shaped braking unit based on pressure rotation

A disc type, pressure technology, used in vehicle parts, brakes, brake components, etc., can solve the problem that medium brake pads are not as good as good quality brake pads

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

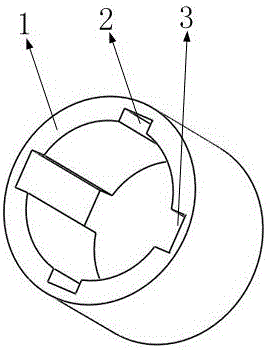

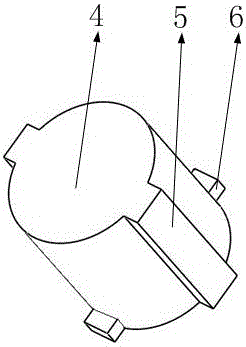

[0028] Such as Figure 6 , 7 As shown, it includes a brake disc 11, a first brake unit 13, a second brake unit 14, and a rotating shaft 15, wherein the brake disc 11 is installed on one end of the rotating shaft 15, and the first brake unit 13 and the second brake unit 14 are identical in structure and symmetrical The first brake unit 13 and the second brake unit 14 are located on both sides of the brake disc 11.

[0029] Such as Figure 8 , 9 As shown, the first brake unit 13 includes a hydraulic column 16, a brake unit connection shell 17, a brake pad support 18, a power plate 19, a brake unit hydraulic shell 20, a force spring 21, a threaded hole 23, a first support plate 24, The second support plate 25, telescopic structure 26, wherein as Figure 6 As shown, the brake unit connection shell 17 is installed on the brake unit hydraulic shell 20 and the internal cavity of the two communicates; the first brake unit 13 and the second brake unit 14 are connected to each other...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com