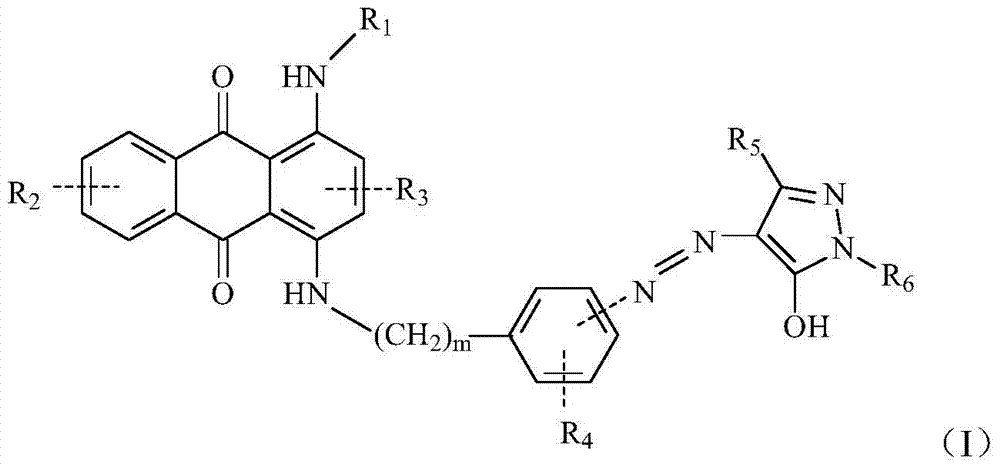

Green dye and its preparation method, ink and electrowetting display

A green dye and ink technology, applied in inks, organic dyes, azo dyes, etc., can solve the problems of lack of green, high contrast, insufficient color spectrum, etc., and achieve bright colors, good light fastness, and high molar extinction coefficient. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

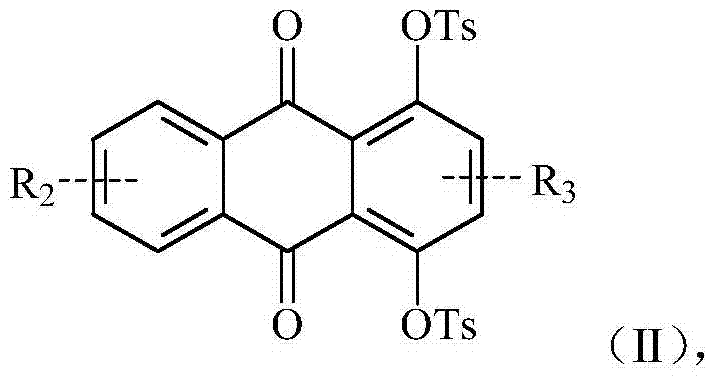

[0036] 1.1 Synthesis of the first intermediate

[0037] Weigh 10g (240g / mol, 0.0416mol) of 1,4-dihydroxyanthraquinone and dissolve it in 200mL of acetonitrile, heat to reflux, add 30mL (101g / mol, 0.2mol) of triethylamine and 19.2g (190g / mol, 0.1mol) p-toluenesulfonyl chloride, reacted for 2h. After the reaction finishes, the reaction solution is poured into 300mL water to separate out the brown product, and obtain the first intermediate with the following structural formula,

[0038] The yield is 94%.

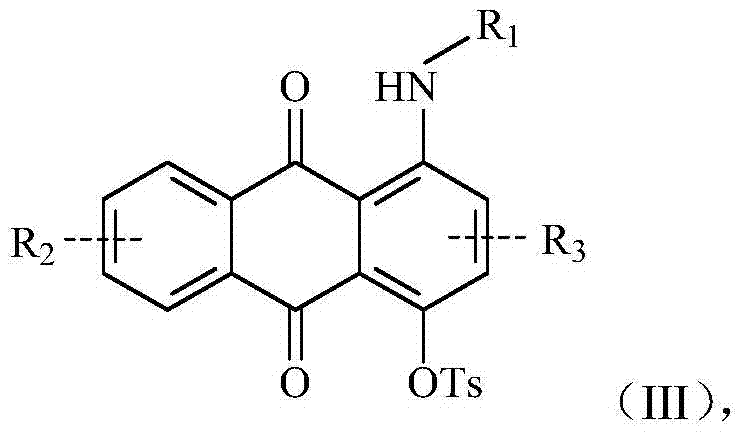

[0039] 1.2 Synthesis of the second intermediate

[0040] Weigh 4.9g (548g / mol, 0.009mol) of the first intermediate and dissolve it in 100mL of chloroform, add 5.8g (129g / mol, 0.045mol) of isooctylamine, heat to reflux for 24h, and remove the solvent by rotary evaporation. The product is separated by column chromatography to obtain the second intermediate of the following structural formula,

[0041] The yield was 88.9%.

[0042] 1.3 Synthesis of the third intermediate...

Embodiment 2

[0050] Weigh 6.6g (132g / mol, 0.05mol) of tert-butoxycarbonylhydrazine and dissolve it in 50mL of n-hexane, weigh 6.7g (114g / mol, 0.058mol) of isooctylaldehyde and slowly add it dropwise to the above solution, heat up to reflux reaction 2h. After the reaction was completed, the solvent was evaporated to dryness to obtain Yield 100%. Will Cool to 0-5°C, weigh 100 mL of 1 mol / L borane tetrahydrofuran solution and slowly add it dropwise to the above reaction device, the developer is dichloromethane / petroleum ether = 1:1, and react for 2 hours to obtain Measure 15mL of concentrated hydrochloric acid, slowly add it dropwise to the above solution, heat to reflux after no obvious bubbles, and react for 0.5h. After the reaction was completed, it was cooled, and the precipitated boric acid was removed by suction filtration, and the solution was rotary evaporated to dryness. get Yield 78%. Measure 10 mL of dehydrated tetrahydrofuran into a 100 mL single-necked flask, weigh 0.29...

Embodiment 3

[0053] A kind of green dye, its structural formula is (Dye 3). 1 g of the green dye was dissolved in 4 g of n-dodecane to obtain electrowetting green ink material G-3.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap