Inflatable type damper floating piston sealing structure

A floating piston, sealing structure technology, applied in shock absorbers, springs/shock absorbers, shock absorbers, etc., can solve the problems of reduced piston movement sensitivity, large frictional resistance, and shortened service life of shock absorbers, so as to improve the Sensitivity and stability, improve service life, prevent mutual leakage effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

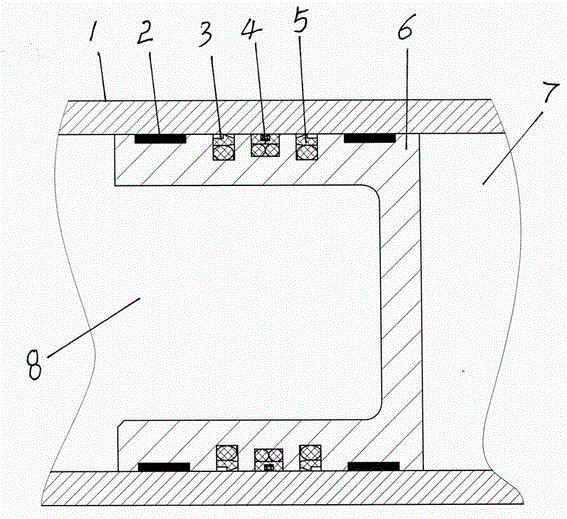

[0007] The embodiment is described in detail in conjunction with the accompanying drawings. It is that an annular guide belt 2 is respectively installed on the outer wall circumference of the floating piston 6 between the hydraulic chamber 8 and the air pressure chamber 7 in the cavity of the piston rod 1 of a pneumatic shock absorber. A gas-liquid sealing ring 4 is fixed on the outer wall middle circumference of the floating piston, and a hole seal 3 and 5 with opposite sealing directions is respectively installed between the gas-liquid sealing ring and the two guide bands. The purpose of setting the sealing ring in the middle of the outer wall of the floating piston is to prevent the hydraulic oil and high-pressure gas on the left and right sides from leaking each other. The guide belt is used to prevent the floating piston from scraping against the inner wall of the piston rod and destroying its sealing performance when the floating piston is subjected to external force. The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com