Air blowing and drying device for flat tube profiles

A drying device and flat tube type technology, which is applied in the direction of drying gas arrangement, drying, drying machine, etc., can solve the problems of difficult to maintain profiles, product quality decline, loud noise, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with the examples shown in the accompanying drawings.

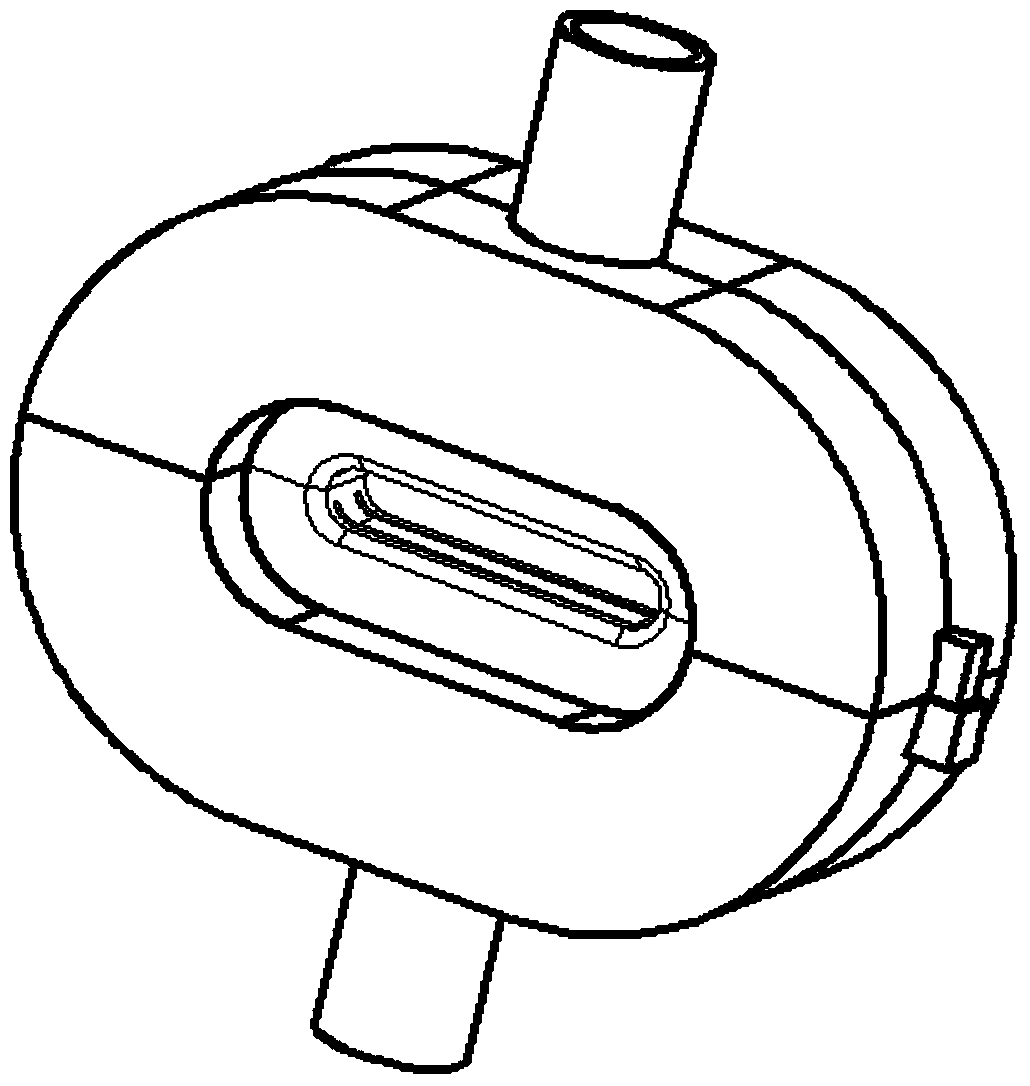

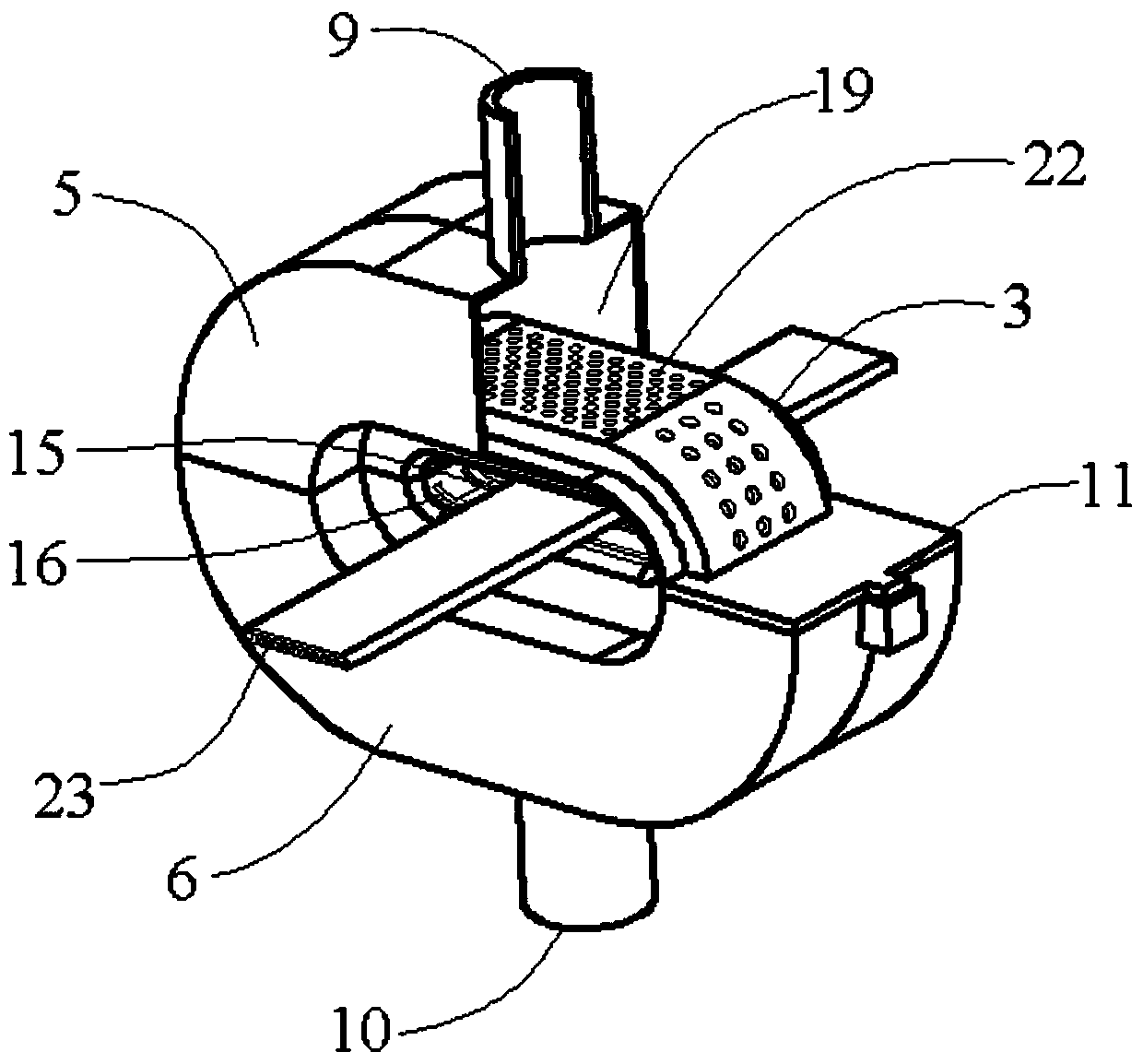

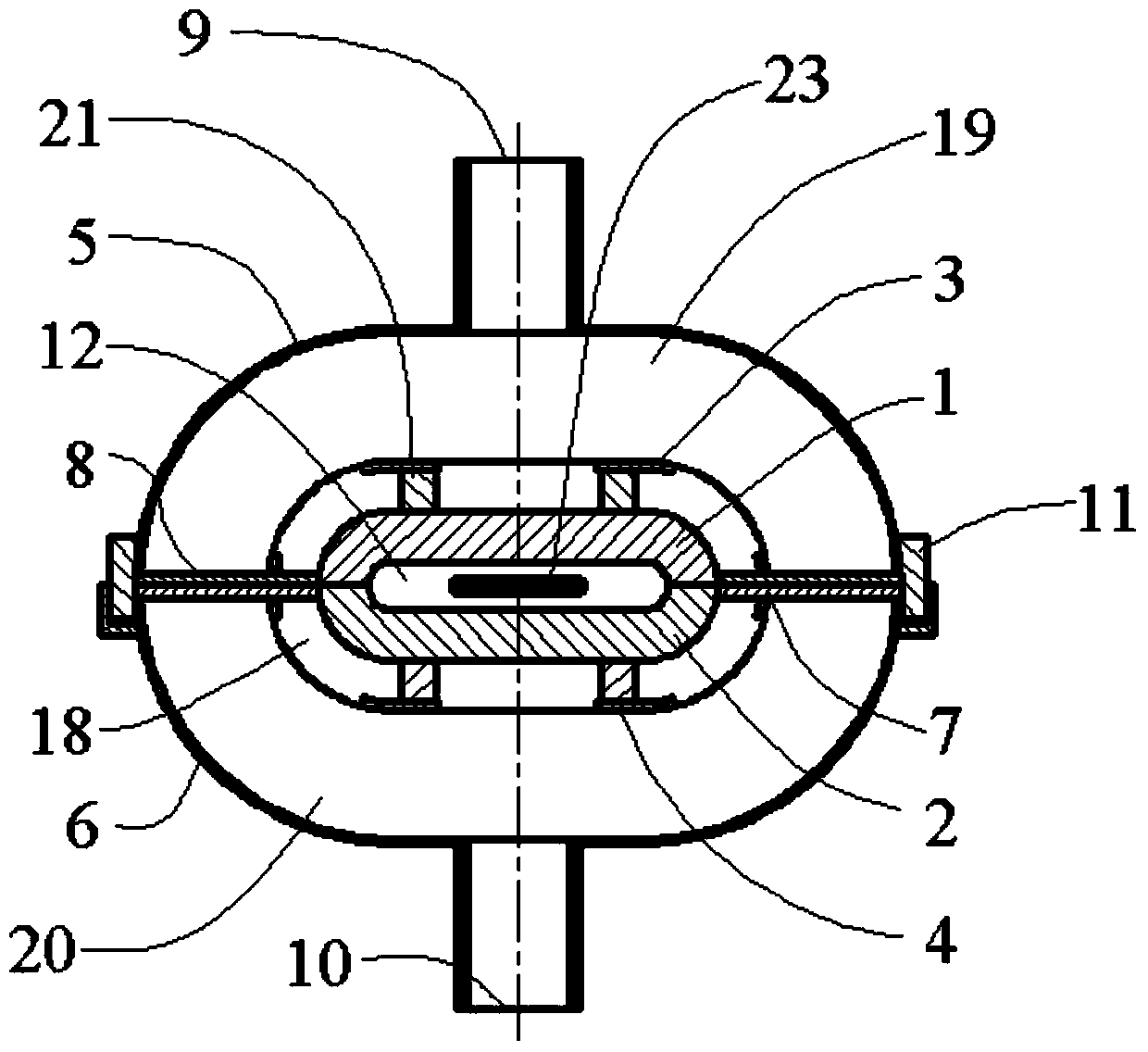

[0019] see figure 2 and image 3 , the present invention provides a blowing drying device for maintaining position stability and noise reduction function, which mainly includes inserts (1, 2), annular grooves (3, 4), shells (5, 6), partitions (7 , 8), air intake holes (9, 10) and positioning fastening components (11). Parts 1, 3, 5, 7 and 9 form the upper part of the air drying device, and parts 2, 4, 6, 8 and 10 form the lower part of the air drying device.

[0020] In the upper and lower parts of the device, the inserts (1, 2) and the annular grooves (3, 4) surround a profile pulling channel (12). Air gaps (13, 14) are provided between the insert (1) and the annular groove (3); and air gaps (15, 16) are provided between the insert (2) and the annular groove (4). The transition profile of the insert (1) at the air gap (13, 14) is rounded. I...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com