Backflow prevention components for adiabatic calorimeters

An adiabatic calorimeter and adiabatic calorimeter technology are applied in the field of backflow prevention components for adiabatic calorimeters, which can solve problems such as inability to measure heat, inability to rise in temperature, and vapor ingress, so as to reduce testing costs, control heat loss, The effect of reducing the impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

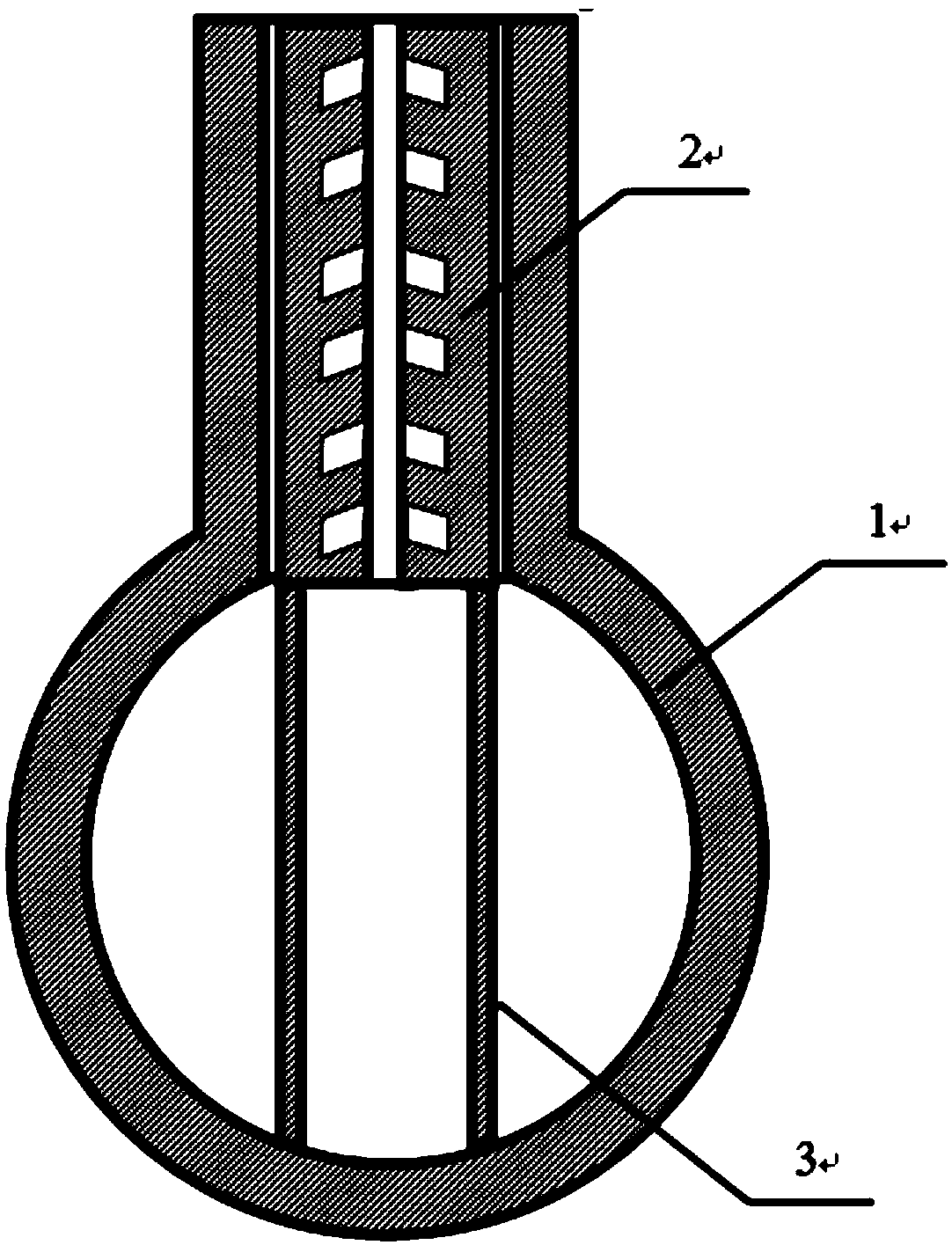

[0014] In order to further understand the anti-reflux device for the adiabatic calorimeter, the description is as follows in conjunction with the diagram:

[0015] to combine figure 1 , an anti-reflux component for an adiabatic calorimeter of the present invention, a kind of anti-reflux component for an adiabatic calorimeter, the component includes an anti-reflux pipe fitting 2 and a support column 3; / 8 inches in the thermal insulation test ball 1, the anti-backflow pipe fitting 2 extends into the cavity of the thermal insulation test ball 1 through the support column 3 thereon and withstands the cavity wall.

[0016] The anti-reflux pipe fitting 2 is a cylindrical pipe, and 6-8 annular grooves at an angle of 30-60° to the pipe axis are evenly distributed in the pipe. It is used to reduce the diameter of the test bulb, store the condensate returned from the pressure pipe, and reduce the effect of steam return;

[0017] The anti-reflux pipe fitting 2 is made of 316 stainless...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com