Automatic detection system for circuit boards

A technology of automatic detection and automatic detection device, applied in the direction of electronic circuit testing, measuring electricity, measuring device, etc., can solve the problems of wasting manpower, low production efficiency, difficult to meet production needs, etc., and achieve the effect of improving production efficiency and saving labor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

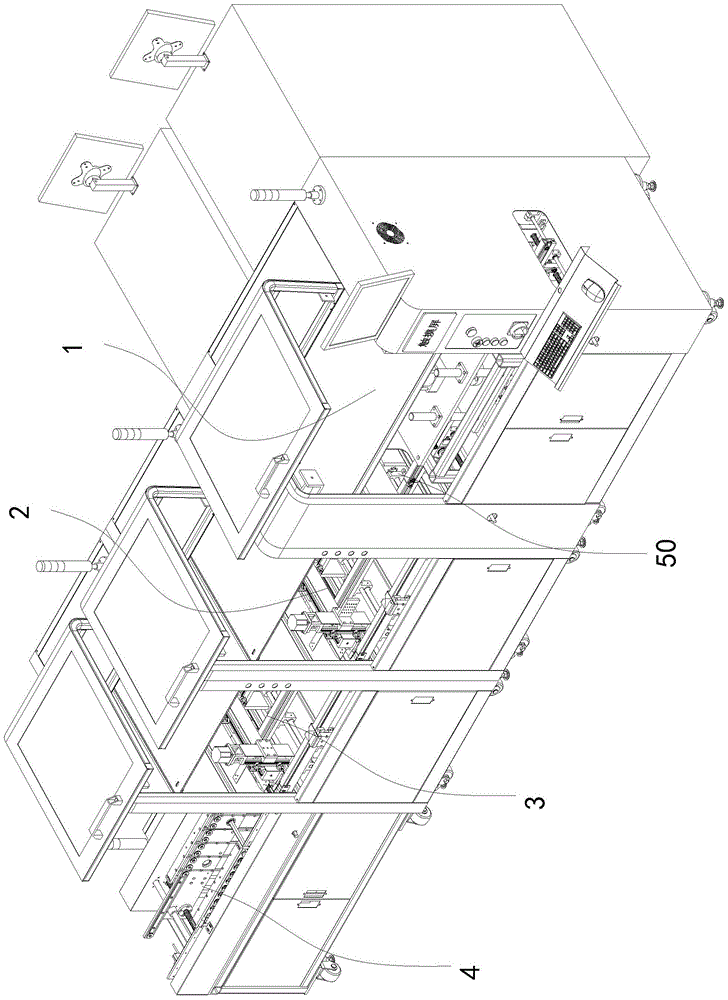

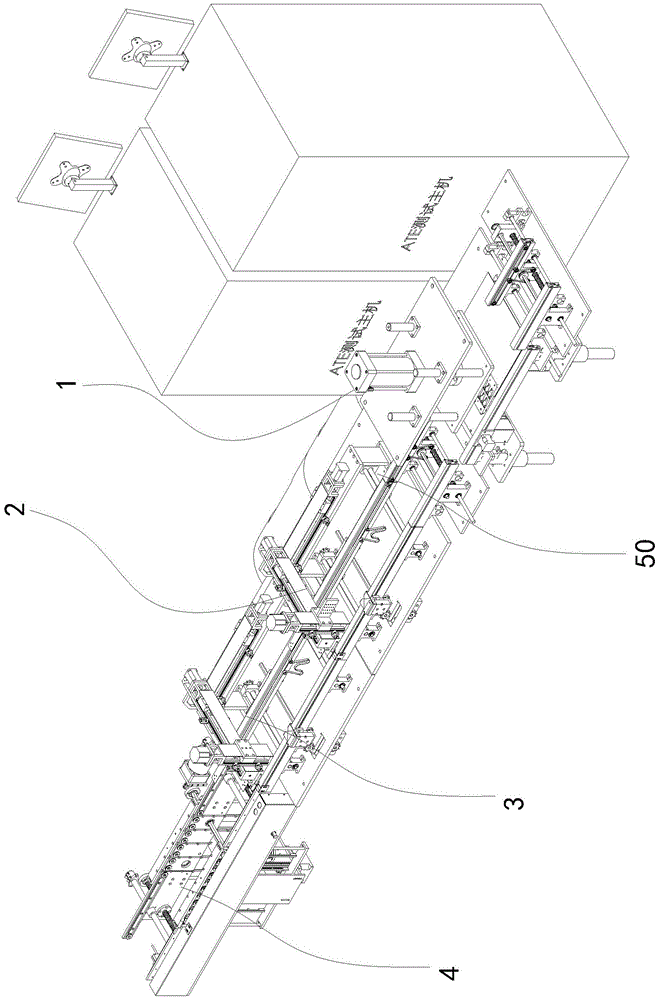

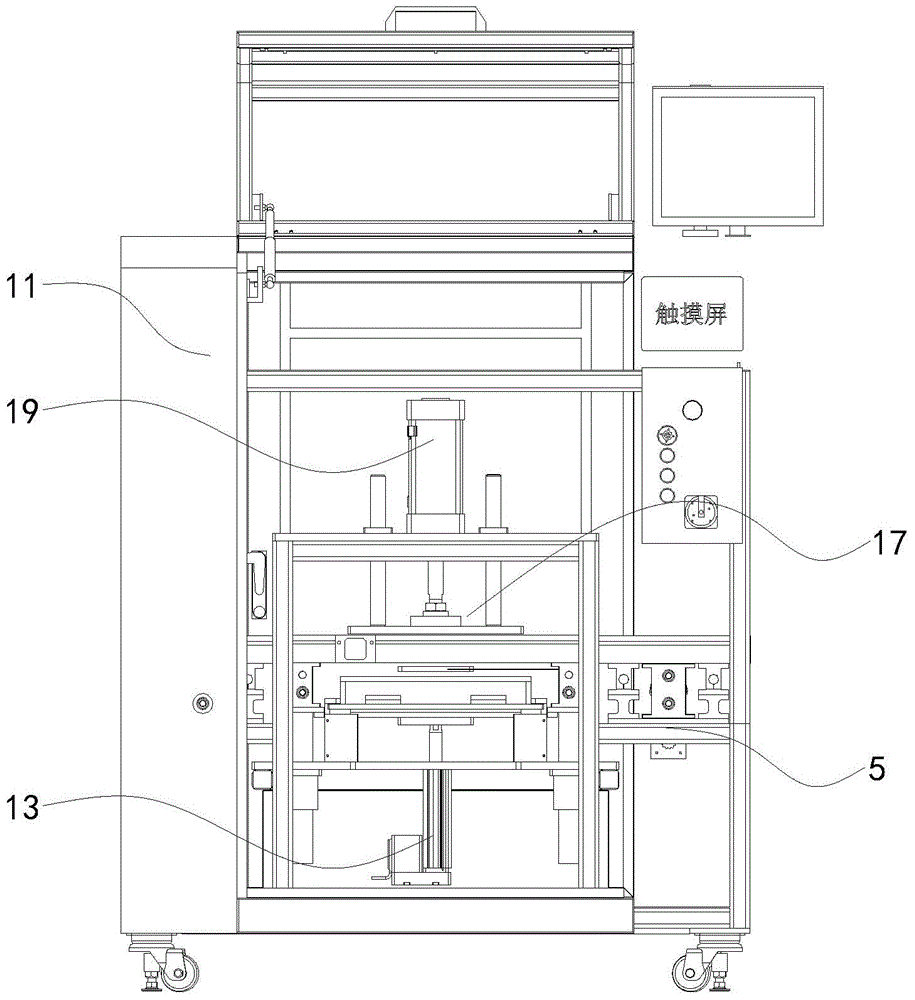

[0029] Such as Figure 1 to Figure 2 As shown, the circuit board automatic detection system includes an automatic detection device 1 connected in sequence, a first coding device 2, a second coding device 3 and a defective product unloading device 4, and also includes a device for transporting the product to be detected to The feeding conveyor device 5 of the automatic detection device 1 and the intermediate conveyor device 50 used to transport the products of the automatic detection device 1 to the first inkjet device 2; the feeding conveyor device 5 is loaded, and the product to be detected Transport to the automatic detection device 1 for detection. The automatic detection device 1 includes a commonly used integrated circuit automatic tester, and can also include a workbench or a movable workbench; Coding, the first coding device 2 includes ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com