Hydrophilic composite layer for non-full lamination screen and manufacturing method thereof

A full lamination and composite layer technology, applied in the field of display screens, can solve problems that affect consumer use and visual effects, and achieve the effects of not easy to fall off, solve the problem of water mist, and increase light transmittance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

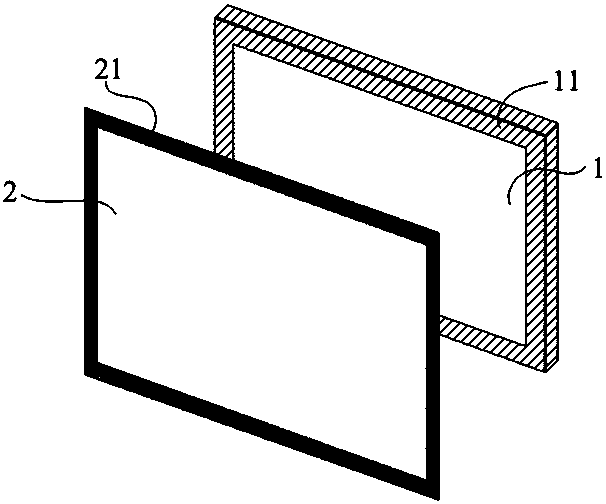

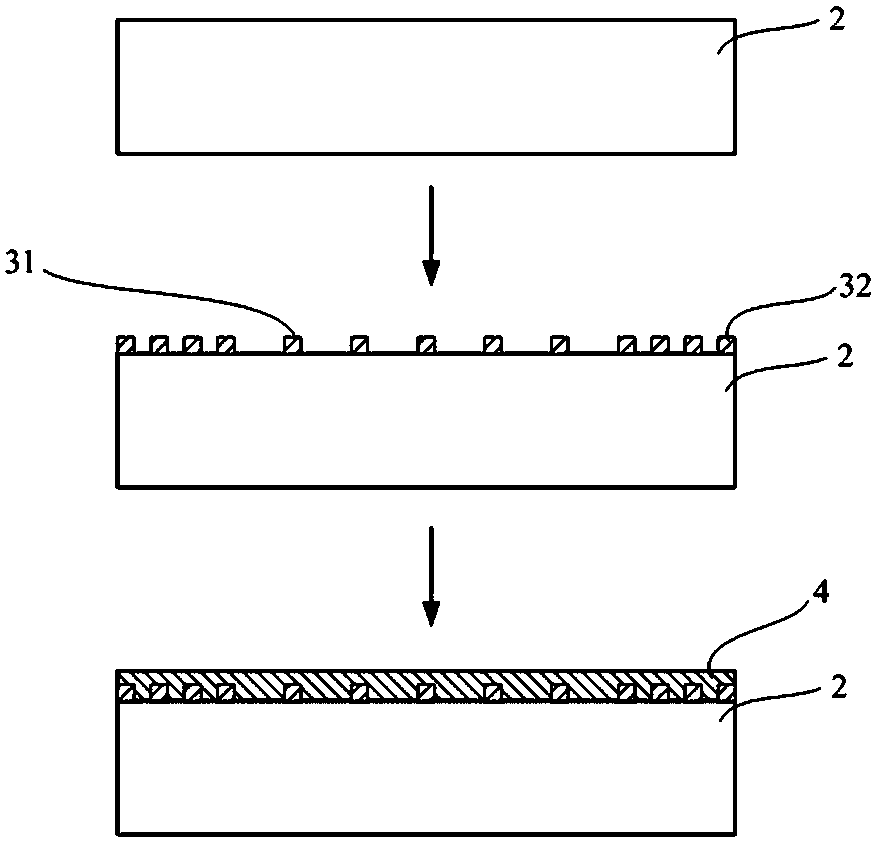

[0038] Such as image 3 As shown, in a preferred embodiment, the hydrophilic composite layer for the non-full lamination screen is made through the following steps, that is, the method for making the hydrophilic composite layer for the non-full lamination screen of the present invention is as follows:

[0039] Step 1, cleaning the first surface of the outer screen that is not fully laminated.

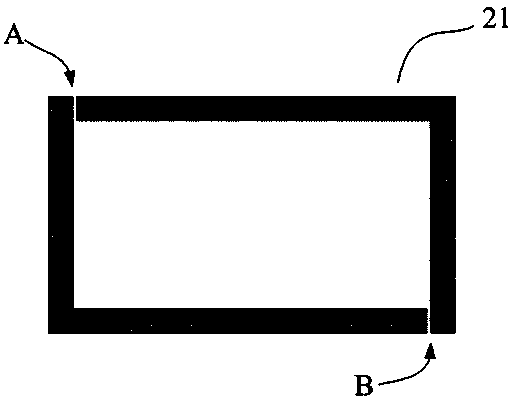

[0040] In this step, the outer screen 2 is cleaned. At this time, the outer screen 2 is not bonded to the inner screen, and there is no adhesive structure 21 on it, so it is a whole piece of plastic or glass without attachments, generally rectangular. It has two surfaces (without considering the four sidewalls extending along its thickness direction), one of which is the surface to be bonded to the inner screen 1, here as the first surface.

[0041] Conventional techniques for cleaning plastic or glass in this field can be used, such as ultrasonically cleaning the outer screen 2, especi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com