Electromagnetic coil winding tool

A technology of winding tools and electromagnetic coils, which is applied in coil manufacturing and other directions, and can solve problems such as difficult demoulding and loose coils

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

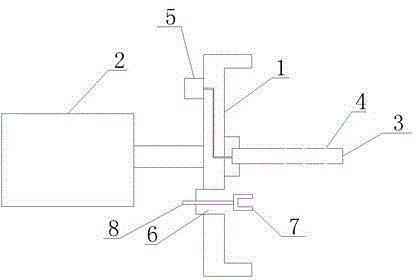

[0014] Such as figure 1 Among them, an electromagnetic coil winding tool includes a circular winding reel 1, one side of the winding reel 1 is connected to the power output shaft of the motor 2, the motor 2 can drive the winding reel 1 to rotate during operation, and the other side of the winding reel 1 The center of the side is provided with a winding column 3, and the interior of the winding column 3 is provided with a liquid chamber, and its surface is provided with a liquid flow hole 4, which communicates with the liquid chamber, and a heating wire is provided on the inner wall of the liquid chamber, and the paraffin supply The chamber 5 communicates with the liquid chamber through the supply pipe. During work, the paraffin supply chamber 5 injects liquid paraffin into the liquid chamber through the supply pipe, and the heating wire on the inner wall of the liquid chamber can heat or maintain the temperature of the paraffin liquid in the liquid chamber without making it Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com