Front patch panel cabinet

A front wiring and cabinet technology, which is applied in the direction of busbar/line layout, substation/power distribution device shell, electrical components, etc., can solve the problems of overall unsightly appearance, inconvenient disassembly and assembly of components, etc., and achieve increased installation space and increased The effect of the number of installs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

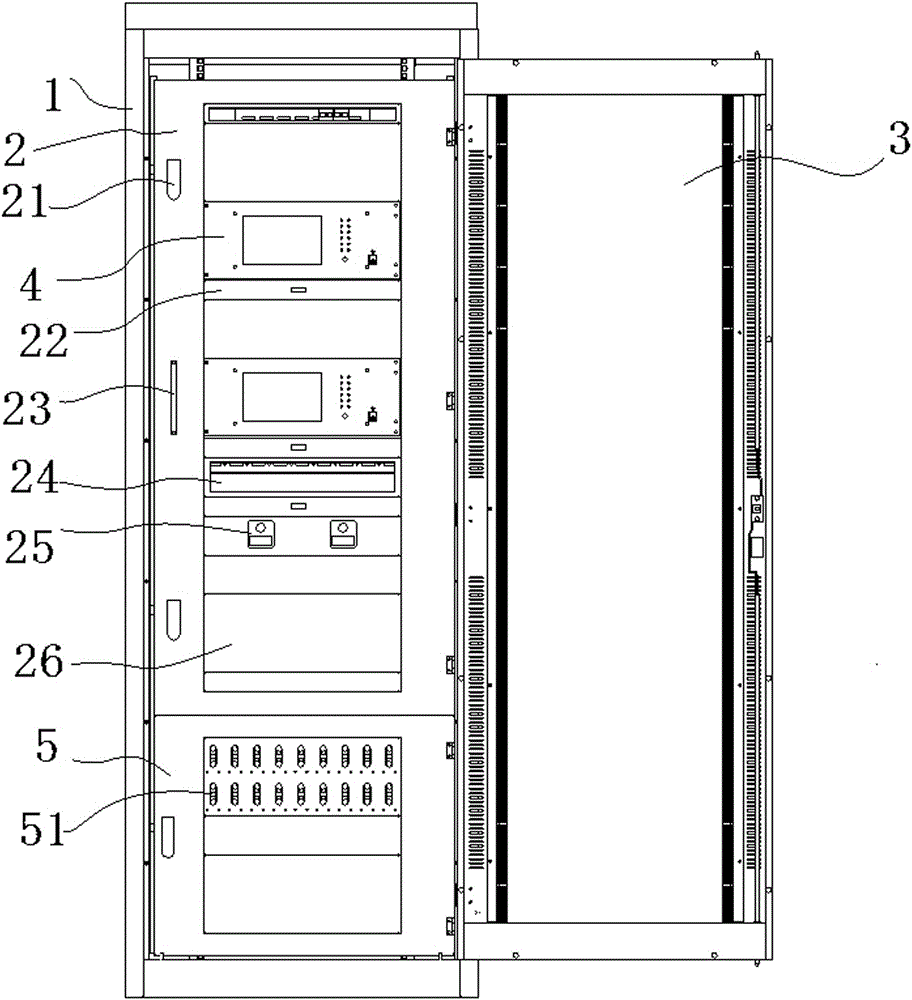

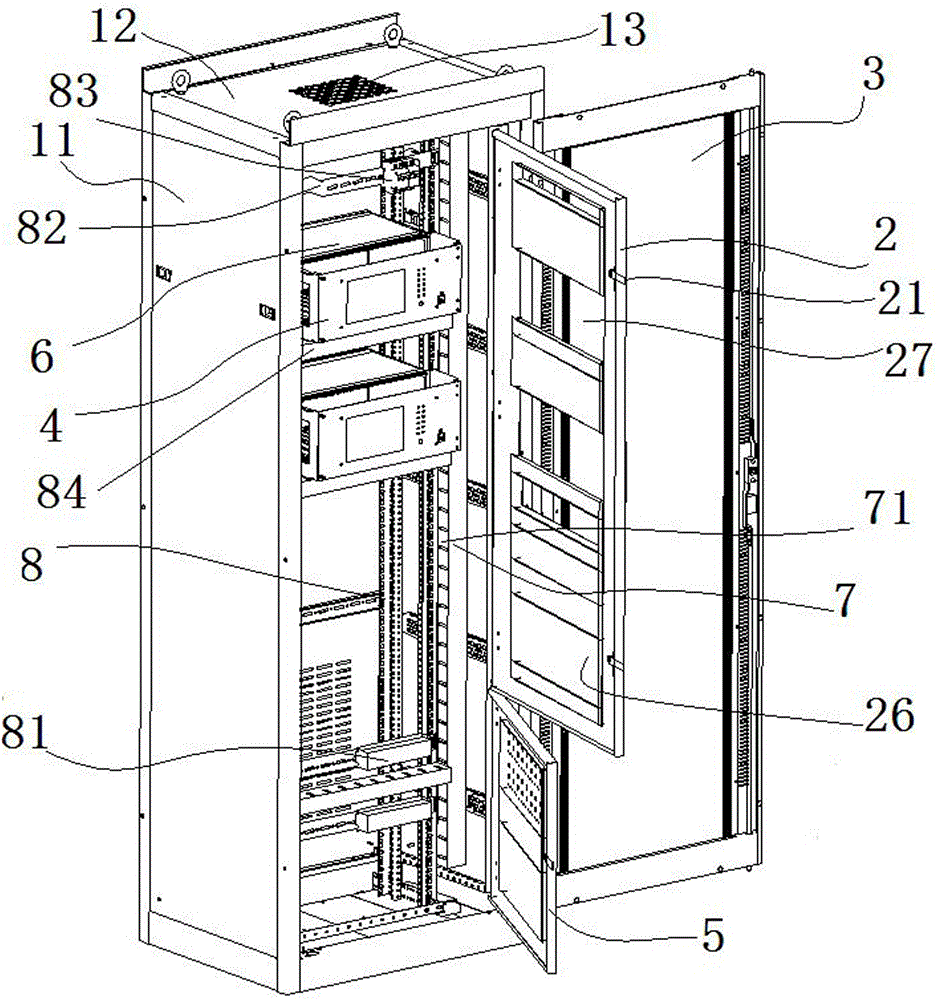

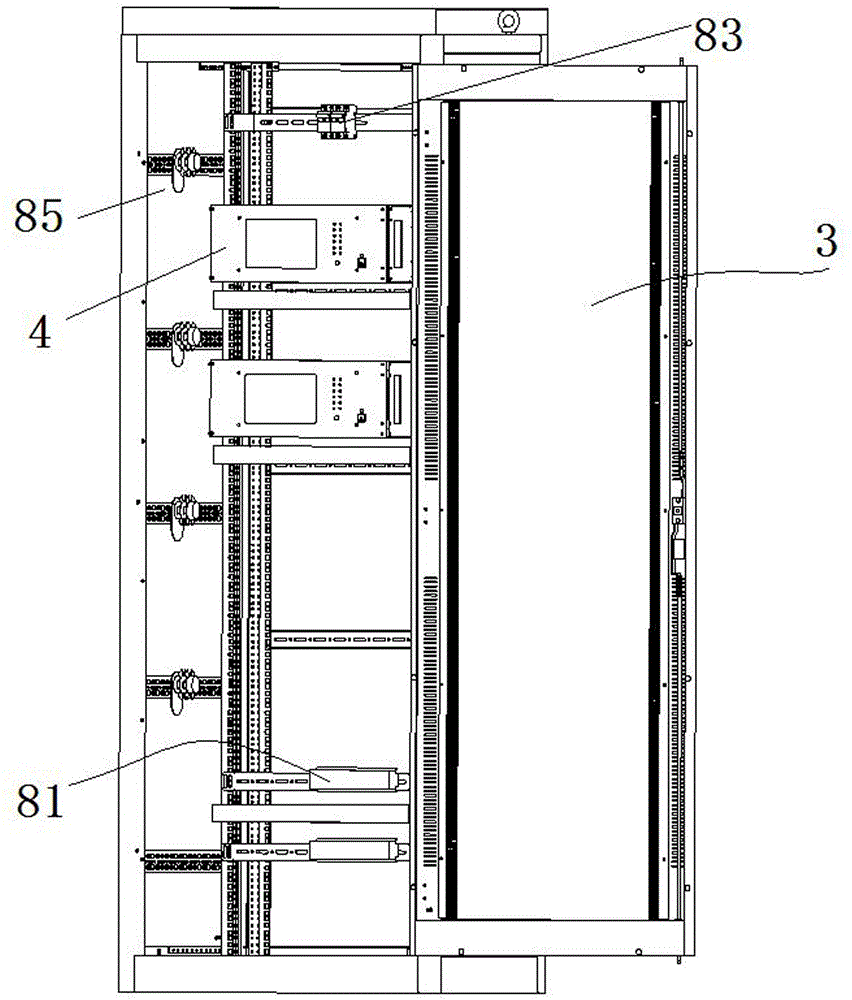

[0020] The embodiment of front wiring panel cabinet of the present invention: as Figure 1-3 As shown, the front wiring panel includes a panel body, and the panel body includes a cuboid panel box 1 and a panel frame 8 disposed in the panel box 1 for installing corresponding components. The panel box body 1 includes a box body and an outer cabinet door 3 hinged on the front side of the box body. The box body includes a left side panel 11, a right side panel, an upper cover panel 12, and a lower bottom panel. The outer cabinet door 3 is arranged on On the right side plate, the hinge axis of the outer cabinet door 3 and the right side plate is along the up-down direction. The outer cabinet door 3 is a glass door capable of full display. The panel frame 8 is centrally arranged in the left and right directions of the panel cabinet, and the optical fiber channel for arranging optical fibers and the cable for arranging cables are respectively formed between the panel frame 8 and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com