Tobacco air-curing shed

A technology for airing tobacco and sheds, which is applied in the field of tobacco airing sheds to achieve the effects of precise adjustment, uniform distribution, and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

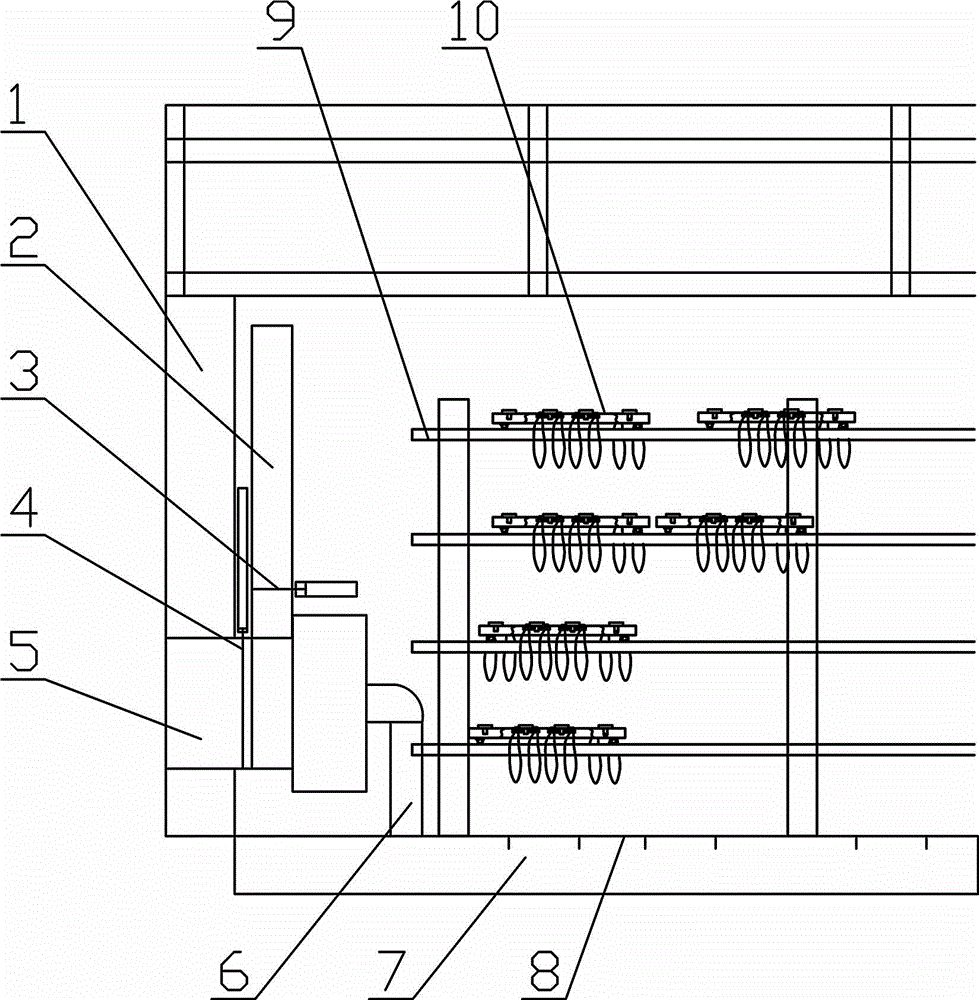

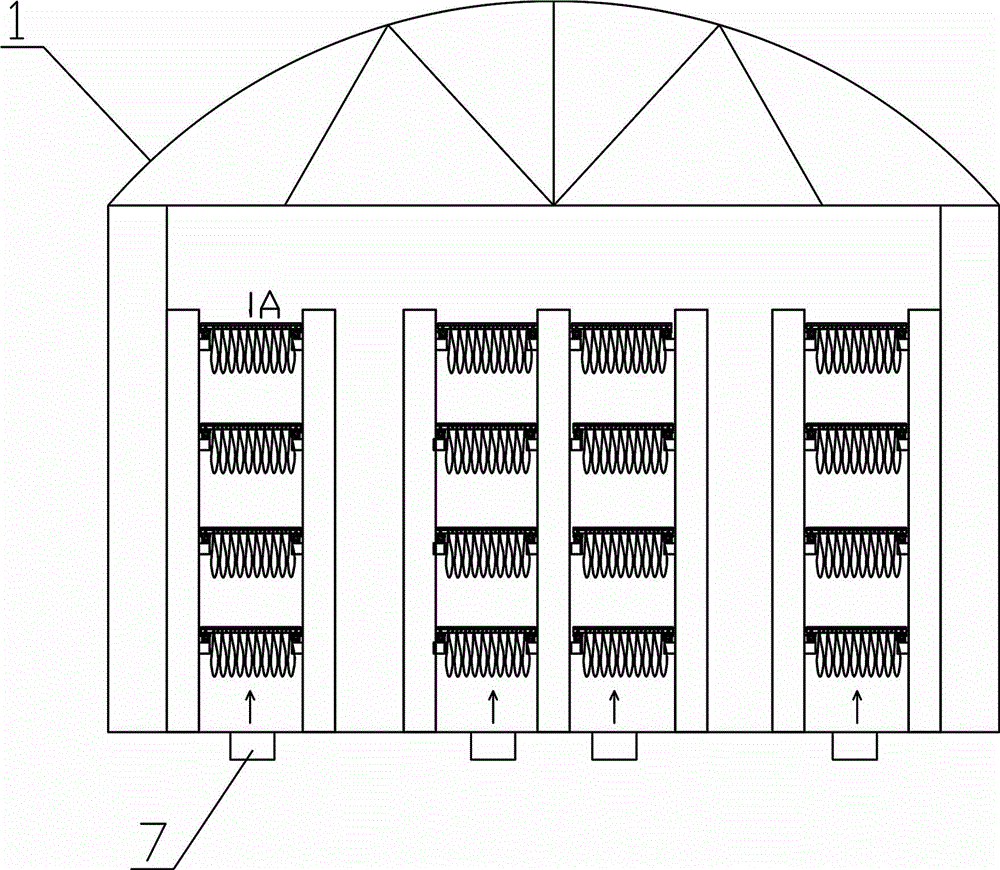

[0025] Such as figure 1 , 2 Among them, a smoke shed, the ground of the shed body 1 is provided with an underground air duct 7, the underground air duct 7 is located below the tobacco rack 9 and is provided with a plurality of air supply ports 8, and the air outlet of the blower 11 passes through the air supply pipe 6 and The underground air duct 7 is connected. Air is blown into the tobacco drying rack 9 from below, which is convenient to make the air more evenly distributed, and avoids the phenomenon that some tobacco leaves are moldy and rotten. And adopt the design of underground air duct 7, the cost is lower.

[0026] The air inlet of blower 11 is connected with air inlet pipe 5 . This structure is conducive to the introduction of fresh air. When the humidity in the environment is lower than the humidity in the smoke shed, the introduction of fresh air can adjust the humidity at a lower cost.

[0027] Such as figure 1 Among them, a circulating air duct 2 is also pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com