Embossed draining floor mat and production process thereof

A production process and floor mat technology, applied in carpets and other directions, can solve the problems of insufficient elasticity, dust and poor ventilation and drainage performance, and achieve the effects of beautiful appearance, optimization of production process, and prevention of mold.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

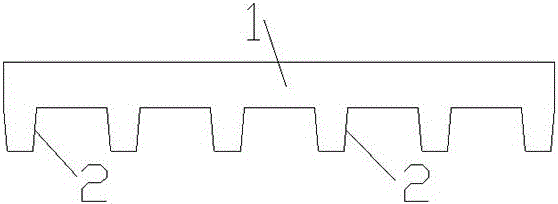

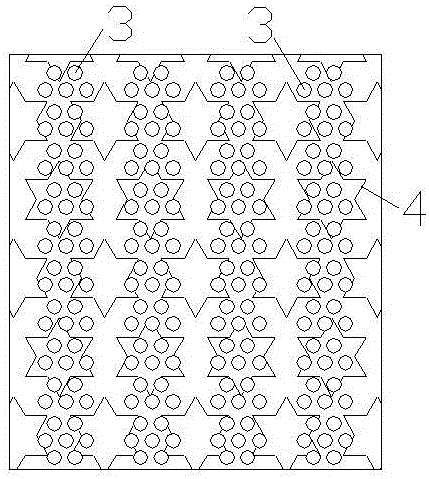

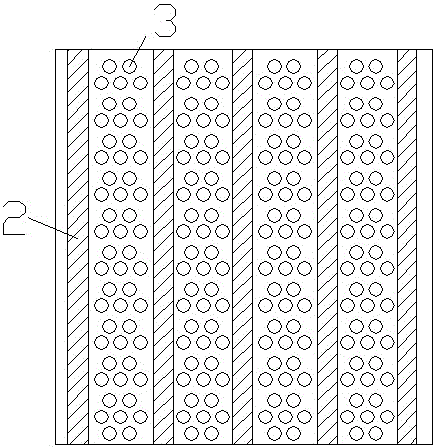

[0016] Such as figure 1 , figure 2 and image 3 As shown, a drainage embossed floor mat includes a floor mat body 1, a plurality of straight-line ribs 2 at equal intervals are arranged at the bottom of the mat body 1, and a number of hollow holes 3 are arranged on the mat body 1 between the ribs 2, and the hollow holes 3 are hollowed out. The hole is triangular or circular or quadrangular or polygonal, and embossing 4 is arranged on the front of the floor mat body 1 .

[0017] The production process of the drainage embossed floor mat of the present invention is to mix and stir PVC, plasticizer and stabilizer evenly according to a certain ratio, then send the mixture to the extruder to extrude the sheet, and roll the sheet at the same time Press to form hollow holes and ribs on the mat body, then cut the bottom and face of the mat body, and then send it to the hot-melt machine to emboss on the front of the mat body.

example 2

[0019] Such as figure 1 , figure 2 and Figure 4 As shown, a drainage embossed floor mat includes a floor mat body 1, a plurality of S-shaped ribs 2 at equal intervals are arranged at the bottom of the mat body 1, and a number of hollow holes 3 are arranged on the mat body 1 between the ribs 2. Embossing 4 on the front of the pad body 1

[0020] The production process of the drainage embossed floor mat of the present invention is to mix and stir PVC, plasticizer and stabilizer evenly according to a certain ratio, then send the mixture to the extruder to extrude the sheet, and roll the sheet at the same time Press to form hollow holes and ribs on the mat body, then cut the bottom and face of the mat body, and then send it to the hot-melt machine to emboss on the front of the mat body.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com