Kitchen micro flow control sealed seasoning cup

A technology of trace control and seasoning cup, applied in the field of seasoning cup, can solve the problems of unsanitary, excessive oil fume, uncontrollable quantity, etc., and achieve the effect of preventing health, controllable amount of seasoning, and preventing long-term contact.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

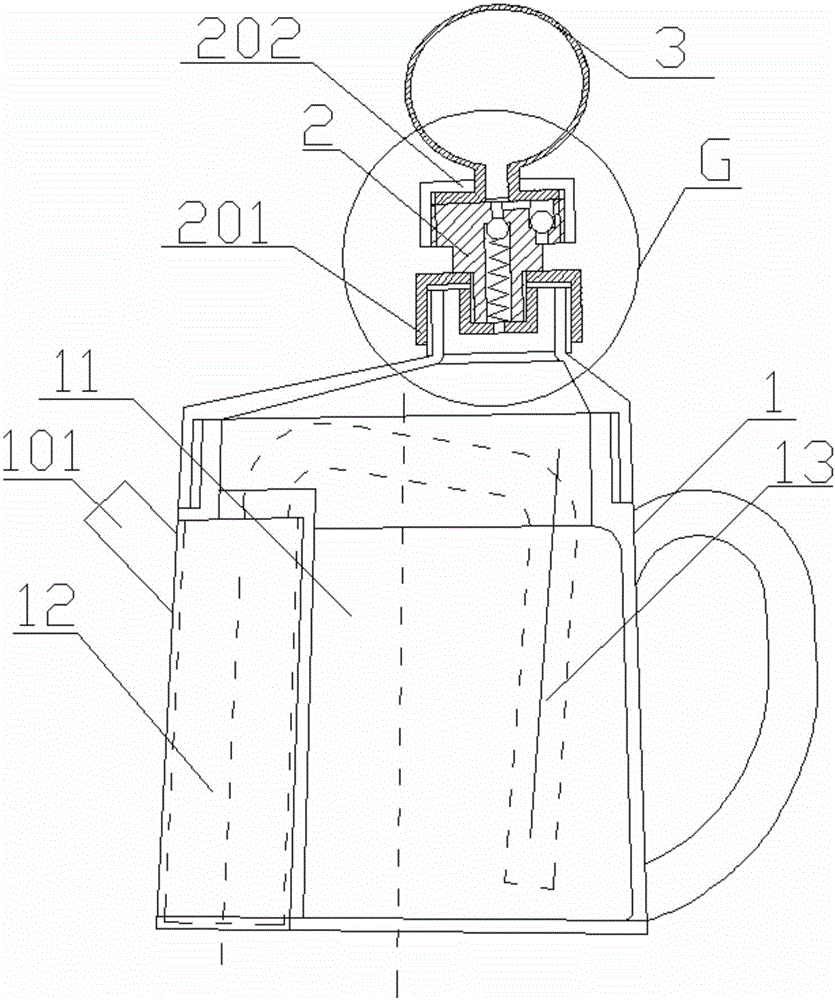

[0027] Such as figure 1 with figure 2 As shown: the kitchen micro-control flow sealed seasoning cup, including the storage cup 1 with a cavity 11 inside, the storage cup 1 is provided with a discharge cup 12, and the discharge cup 12 is connected with the storage cup 1 One end of the communication pipe 13 is connected to the discharge cup 12, and the other end sinks to the bottom of the chamber 11. The storage cup 1 is also provided with a The medium is pressed into the pressurizing device of the discharge cup 12.

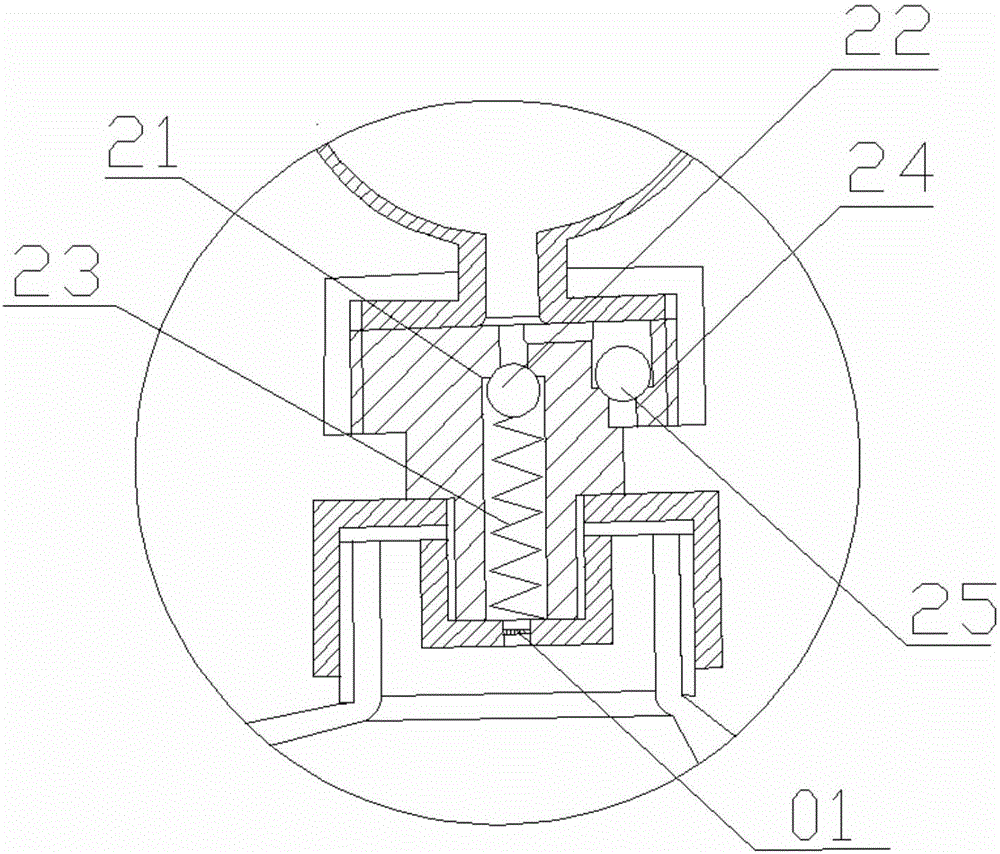

[0028] The pressurizing device includes a valve body 2 connected to the storage cup 1, an elastic air bag 3 connected to the valve body 2, an air intake mechanism arranged on the valve body 2 and an air outlet mechanism arranged on the valve body 2, and During the working process, the air intake mechanism and the air outlet mechanism open and close alternately.

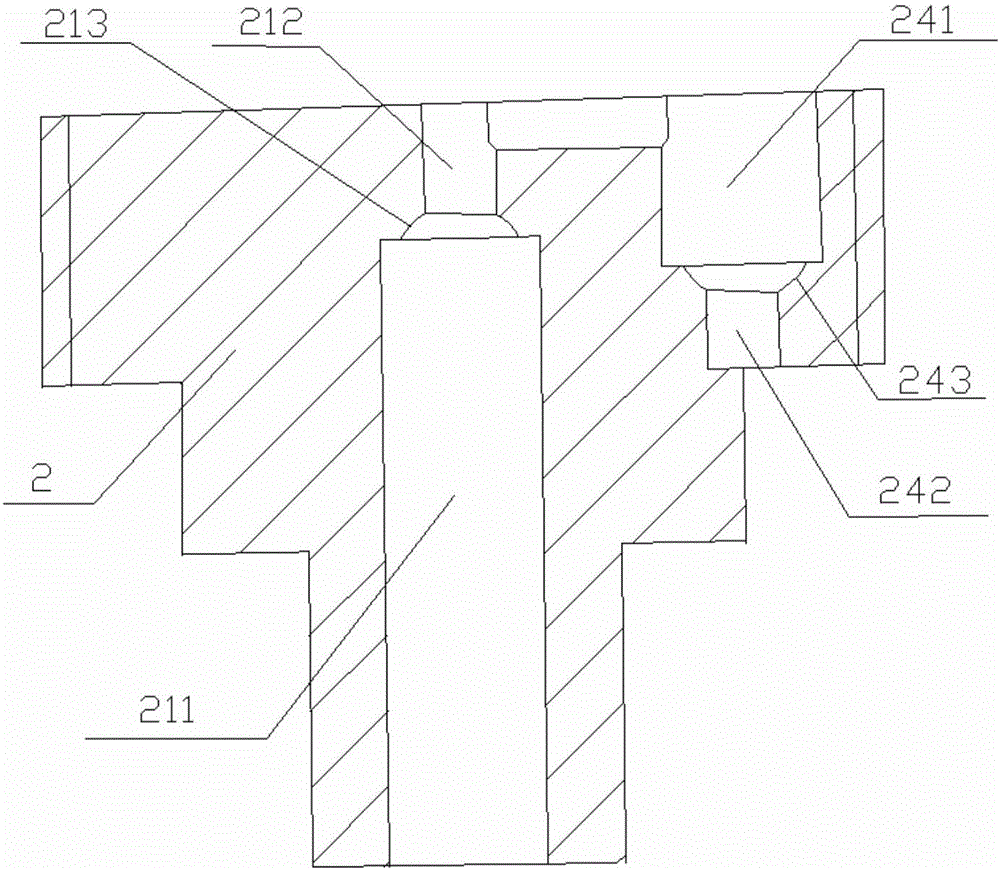

[0029] The air outlet mechanism includes a first channel 21 arranged in the valve body 2 and commun...

Embodiment 2

[0043] Such as Figure 4 As shown: this embodiment is basically the same as the embodiment, the only difference is that the pressurizing device includes a communication tube 13 that communicates with the cavity 11 and the elastic airbag 3 respectively, and the communication tube 13 is provided with a first one-way valve 021, so that the gas can only enter the cavity 11 from the elastic airbag 3, the connecting pipe 13 between the first one-way valve 021 and the elastic airbag 3 is connected with an atmospheric pipe, and the atmospheric pipe is provided with a second one-way valve 022, Make gas can only enter in the elastic air bag 3 from atmosphere.

Embodiment 3

[0045] Such as Figure 5 As shown: this embodiment is basically the same as the embodiment, the only difference is: the pressurizing device is the third air pump 031 communicated with the cavity 11 of the storage cup 1, and no air intake mechanism is needed, because the third The air pump 031 itself has a ventilation function.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com