Demolding method of clear aligners without brackets

An invisible appliance and mold release technology, applied in medical science, prosthodontics, orthodontics, etc., can solve the problems of broken dental molds, excessive force, uneven force application of appliances, etc., to avoid breakage, improve Demoulding efficiency and uniform force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] A demoulding method of a bracketless invisible aligner comprises the following steps:

[0025] 1) Obtain the oral data of the patient, establish a three-dimensional digital model of the patient's oral cavity; design a treatment plan, adjust the teeth to be treated to the target position, and obtain a three-dimensional model of the tooth and jaw.

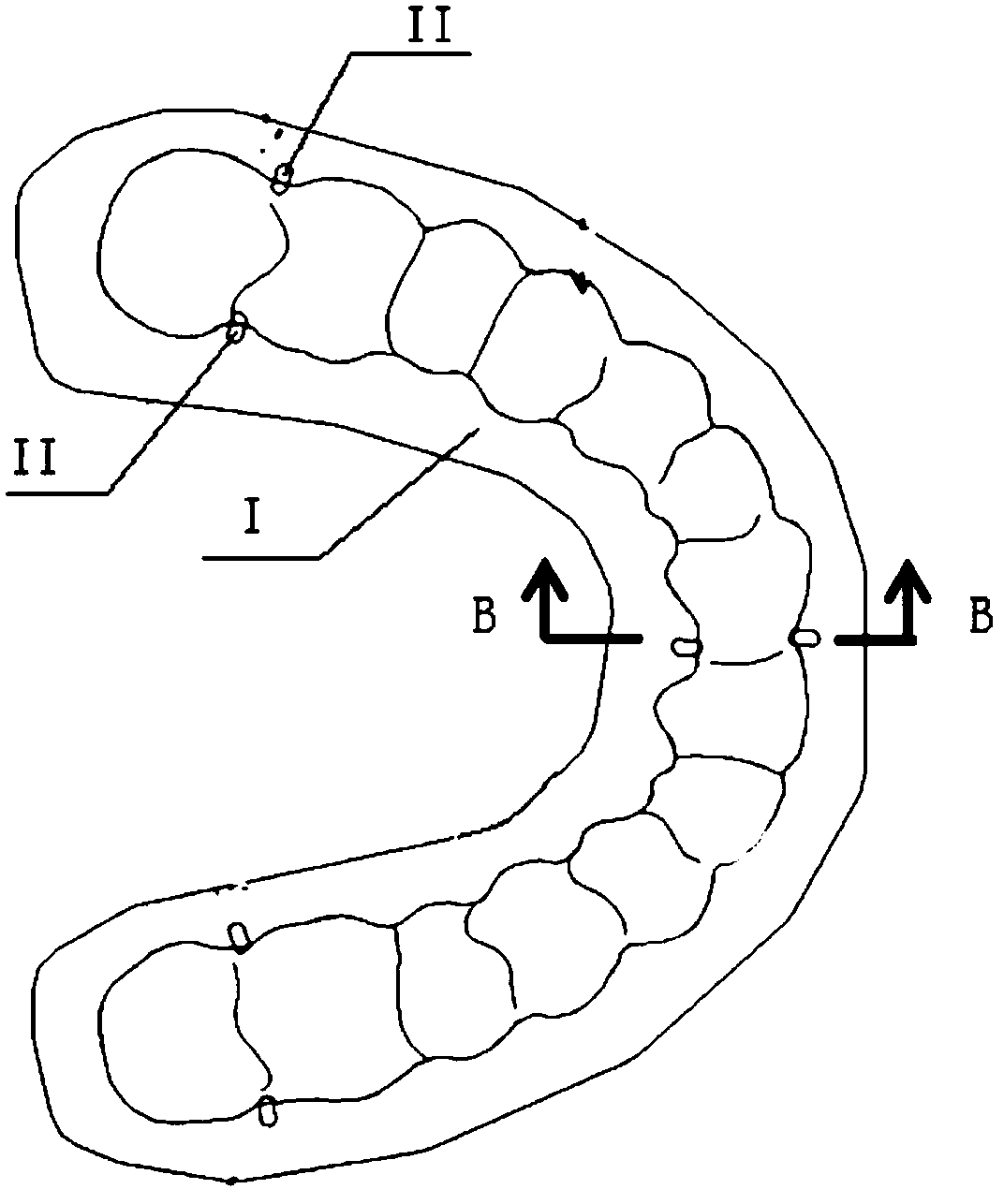

[0026] 2) On the surface of the three-dimensional model of the jaw, design the demoulding holes II along the gum line. The demoulding holes II are arranged in pairs. The two holes of a pair of demoulding holes II are centered, and one hole is located on the lingual side and the other is located on the buccal side. side or labial side, such as figure 1 shown.

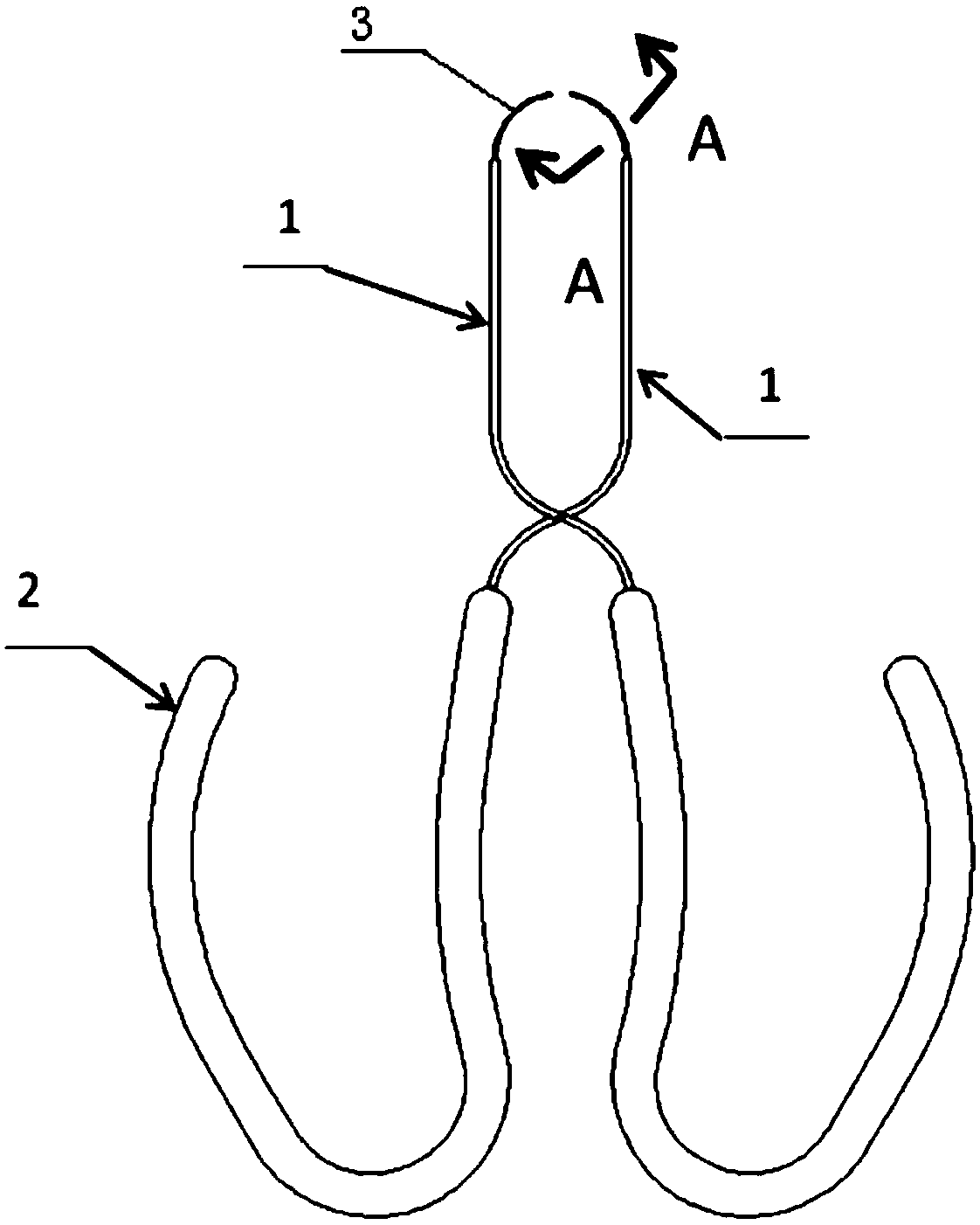

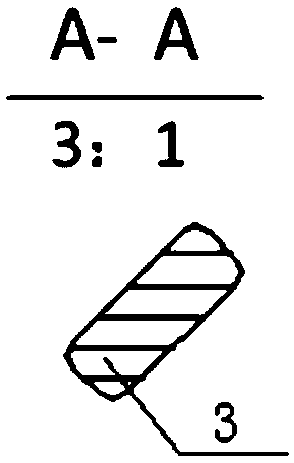

[0027] To make the demoulding hook pliers, respectively bend and shape two steel wires to form the jaw 3, the jaw 2 and the handle 1, and hinge the two steel wires at the joint between the jaw 2 and the handle 1 to form the demoulding hook pliers, Such as figure 2 As...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com