Feeding device applied to filter sieve tube wire winding machine

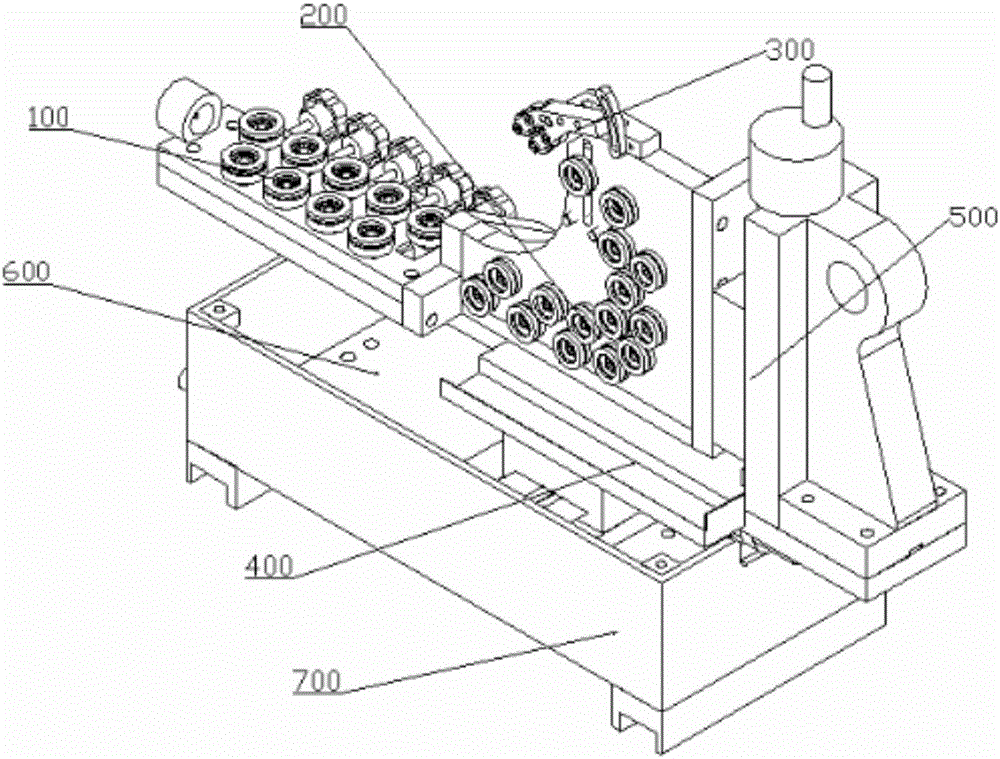

A feeding device and filter screen technology, applied in the field of feeding, can solve the problems of failing to meet customer requirements, affecting the size of product gaps, and not being able to guarantee product roundness, etc., and achieve the effect of beautiful products and control of gap size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] For the purpose of full disclosure, the present invention will be further described in detail below in conjunction with examples. It should be understood that the specific embodiments described below are only used to explain the present invention, and are not used to limit the protection scope of the present invention.

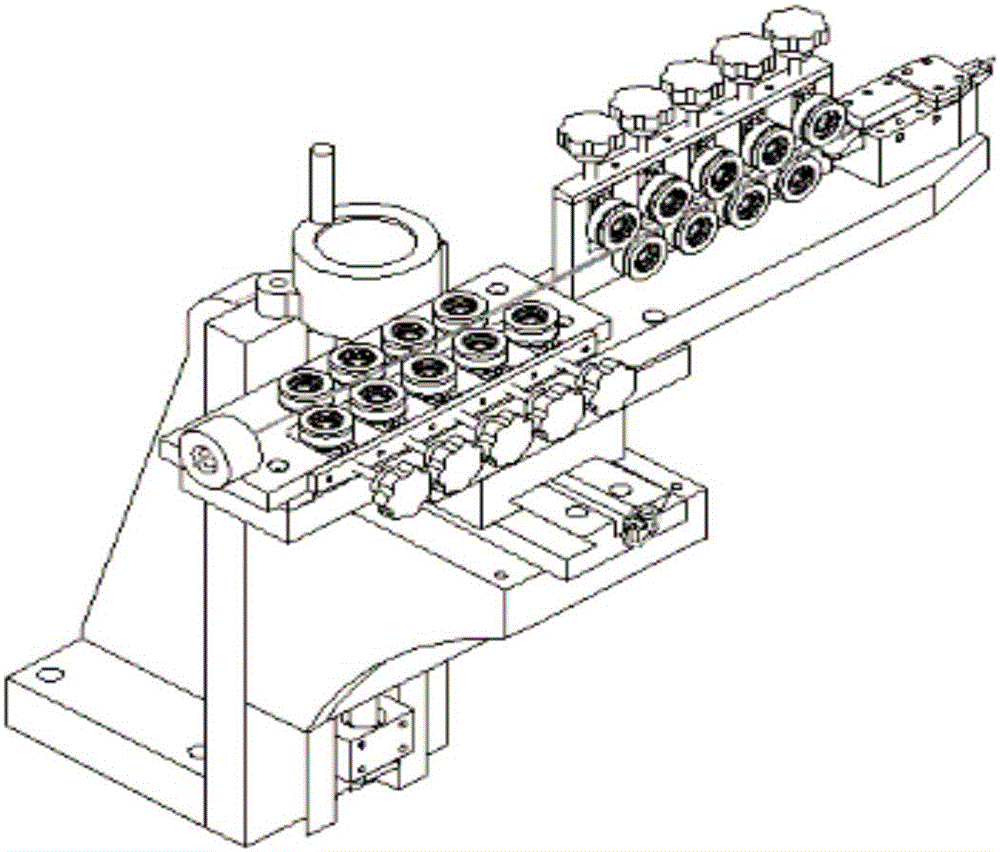

[0028] like figure 1 As shown, the feeding device of the filter screen wire winding machine in the prior art adopts a linear feeding mechanism. The linear feeding mechanism passes through the wire feeding nozzle after passing through the left and right straightening and up and down straightening mechanisms to ensure that the wire is sent out in a straight line. Started to wind the welded screen pipe, but its strength is high when winding the wire. When producing smaller screen pipes, the wire cannot be bent well, and the roundness of the product cannot be guaranteed, which affects the size of the gap in the product, and it is not beautiful and cannot be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com