Manufacturing method for arc-shaped plate milling groove positioning device

A technology of a positioning device and a manufacturing method, which is applied in the field of tooling and fixtures, can solve the problems of cumbersome clamping, complicated tooling, and difficult to guarantee machining accuracy, and achieves the effects of flexible and convenient clamping and use, high processing efficiency, and uniform and balanced force.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings.

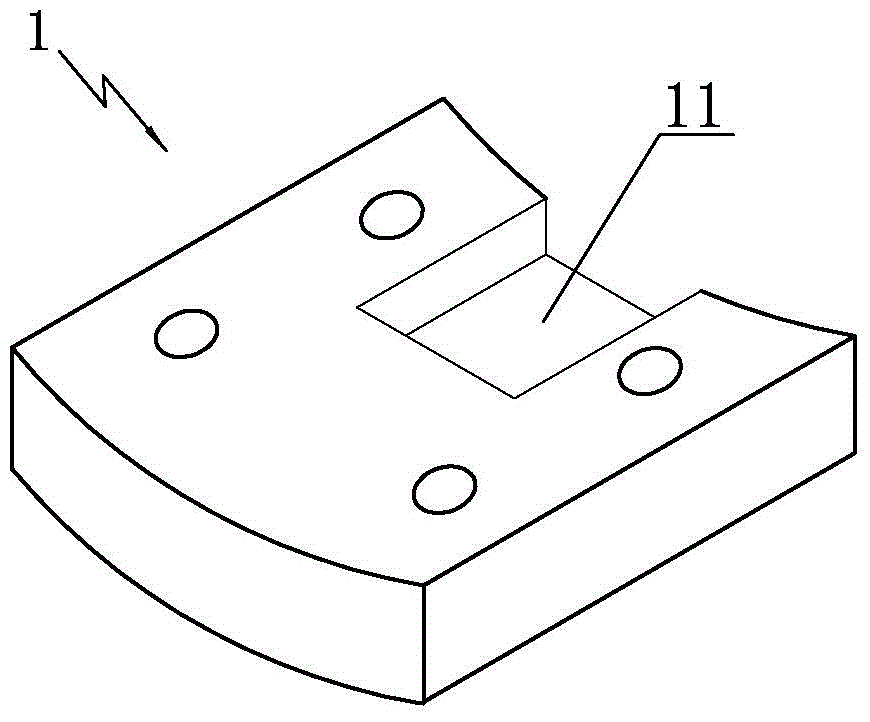

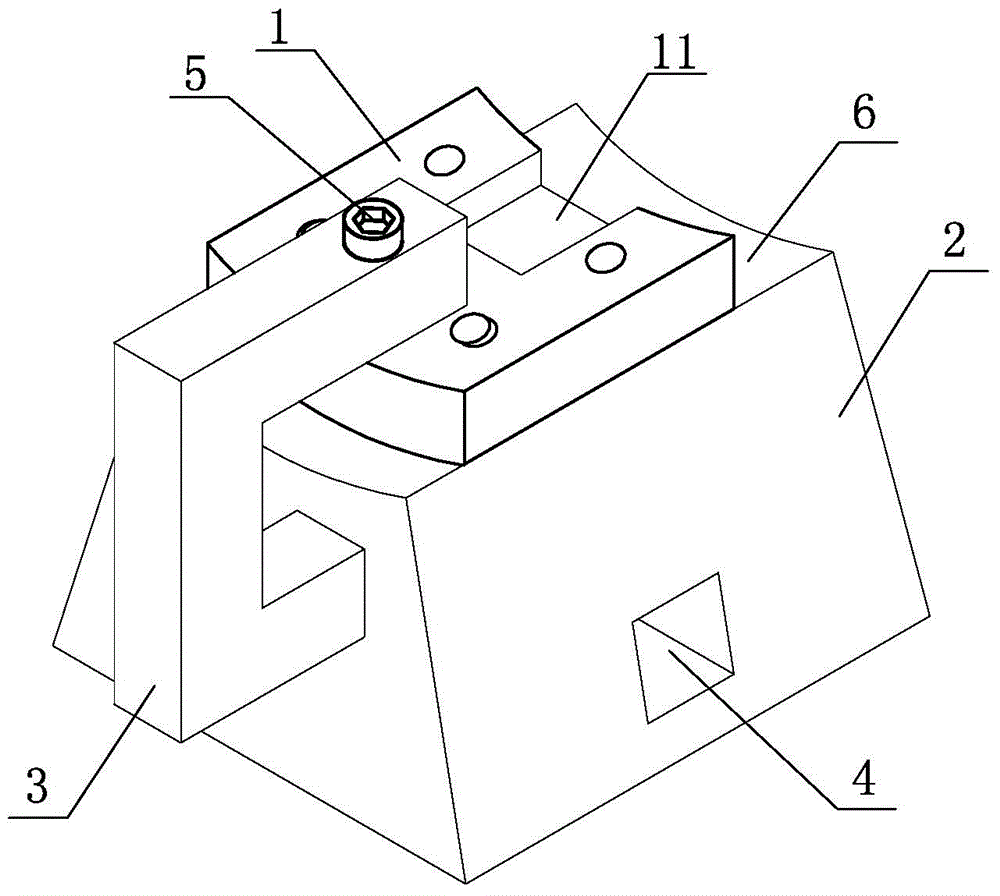

[0014] Such as Figure 1 to Figure 2 As shown, the present invention includes a trapezoidal positioning platform 2, the top surface 6 of the trapezoidal positioning platform 2 is arc-shaped, and the radian of the top surface 6 is the same as that of the arc-shaped bottom surface of the workpiece 1, so that the workpiece 1 and the positioning platform 2 can be closely attached , during processing, the force on the workpiece 1 is uniform and balanced to ensure the machining accuracy. The width of the top surface 6 is the same as the width of the arc-shaped bottom surface of the workpiece 1, which is convenient for the positioning of the workpiece 1 and the positioning table 2, and it is easy to determine whether the positioning reference is accurate. The positioning table 2 Positioning holes 4 are provided on the side walls of the slope, whi...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap