Paper clipping and shaping device

A sizing device and paper technology, applied in the field of slitting technology, can solve the problems of high manufacturing and use costs, difficulty, and inability to cut paper, and achieve low manufacturing and use costs, high cutting reliability, and high cutting efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

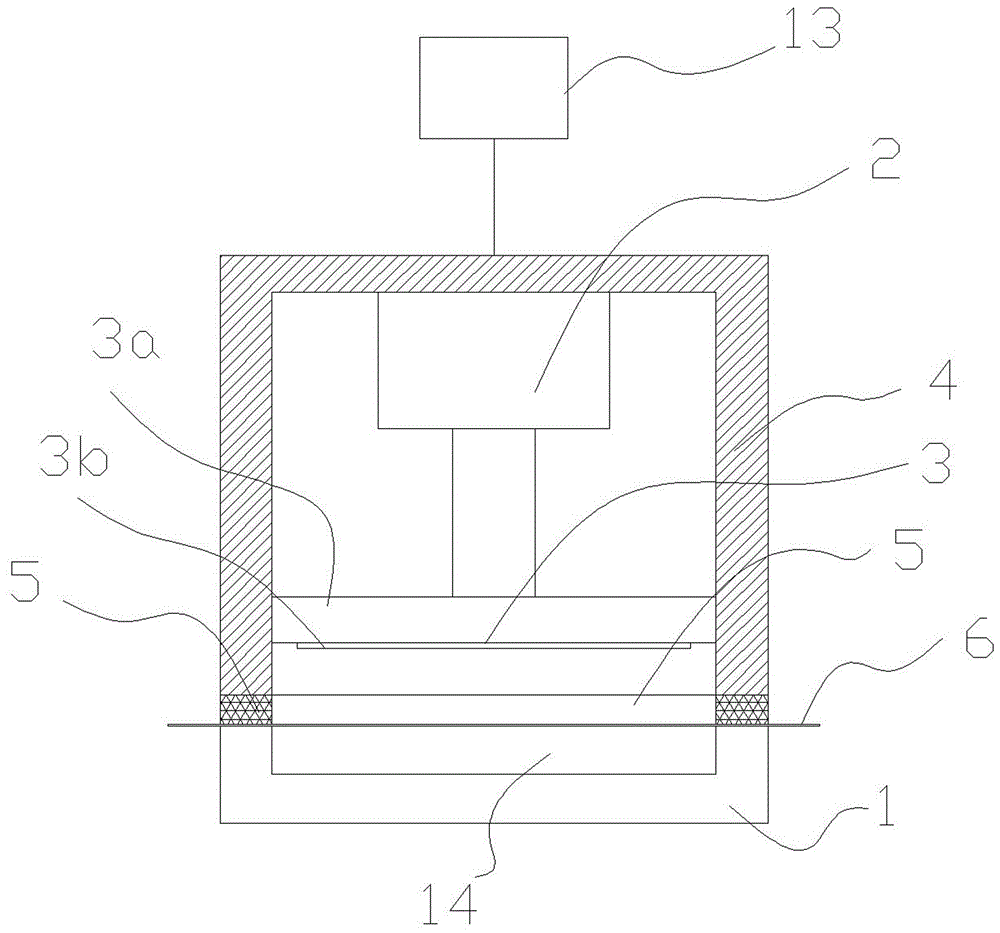

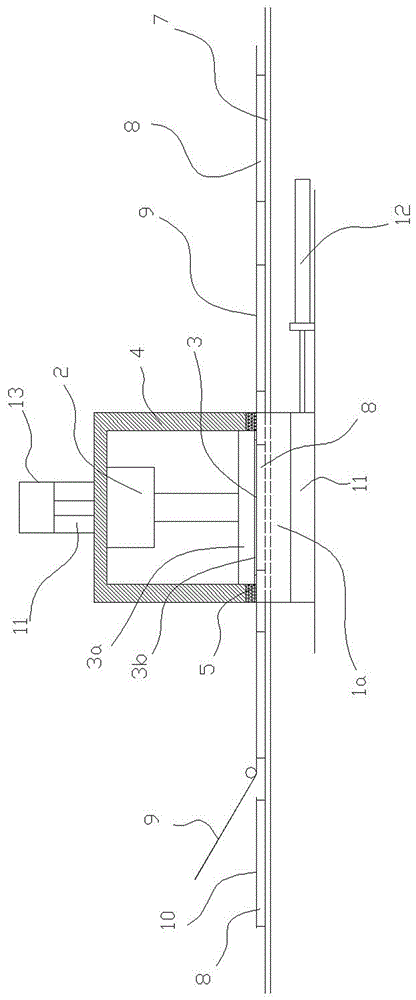

[0012] Now in conjunction with accompanying drawing and embodiment the present invention is described in further detail:

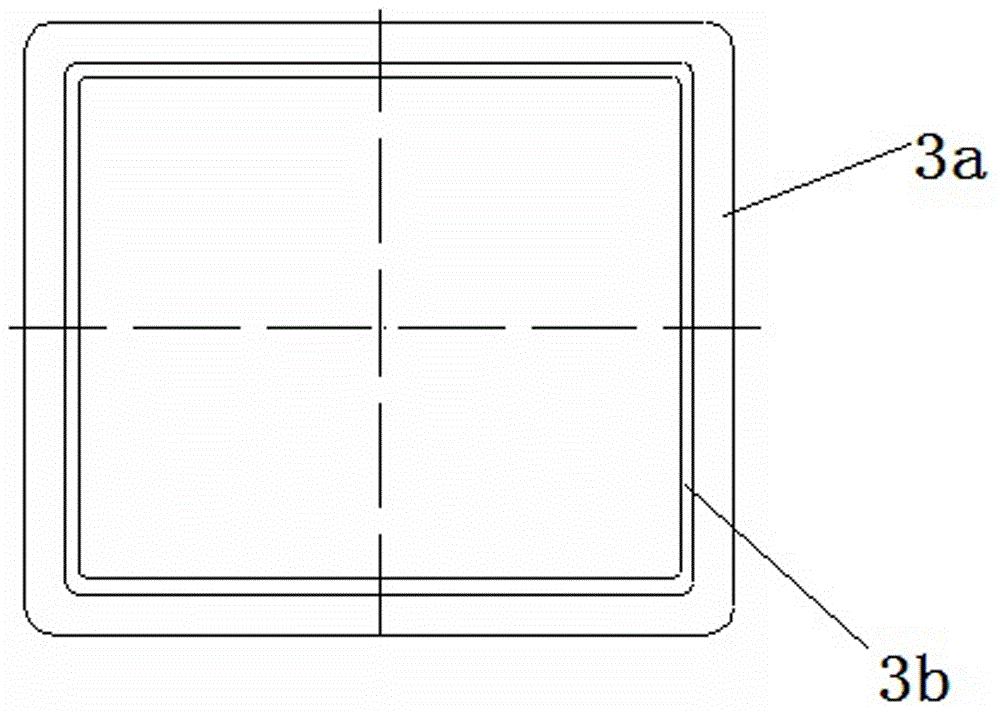

[0013] Such as figure 1 As shown, the present invention includes a base 1, a cutting head 3 that is positioned on the base 1 and is driven by a power 2 to move up and down. A recessed area 14 is provided on the base 1 of the annular heating wire 3b.

[0014] The base 3a is a heat insulator.

[0015] Around the cutting head 3, a cylindrical body 4 driven by a power 13 to move up and down is arranged.

[0016] The lower end surface of the cylinder body 4 is provided with a soft body 5 in order to press the paper 6 on the base 1 more effectively.

[0017] Such as image 3 As shown, the base 1 is two slats 1a and is located on both sides of the conveyor belt 7, and a recessed area 14 is formed between the two slats 1a (not shown in the figure due to the occlusion of the slats 1a), so that The mosaic tiles 8 on the conveyor belt 7 pass through, and the pap...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com