Printing method for special-face conical bottles on common screen printing machines

A technology of screen printing machine and printing method, applied in screen printing machine, printing machine, rotary printing machine and other directions, can solve the problems of large curvature of the bottle body close to the bottle mouth, unable to print, and unclear printing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The specific implementation manner of the present invention will be further described in detail below in conjunction with the accompanying drawings.

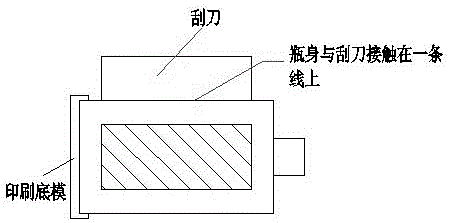

[0037] Ordinary screen printing machines generally include a printing bottom mold, a printing nozzle, a bottle holder fixture, a screen plate, a scraper and a driving mechanism. Fix the bottle with the printing nozzle, then the printing bottom mold, the bottle, and the printing nozzle rotate coaxially at the same time, and then the scraper moves horizontally and linearly under the action of the driving mechanism to scrape the ink onto the bottle to complete the printing.

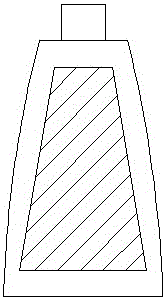

[0038] Such as image 3 and Figure 4 As shown, the characteristics of ordinary bottle printing are:

[0039] (1) The printing bottom mold, bottle and printing nozzle rotate around the same axis at the same time (see image 3 );

[0040] (2) The scraper moves linearly on the screen relative to the bottle (see Figure 4 ).

[0041] According to the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com