Packing machine stretch bag method

A technology for opening bags and packaging machines, applied in packaging and other directions, can solve the problems of unsmooth opening of bags, heavy workload, and high energy consumption, and achieve the effect of reducing quantity, reducing workload, and reducing energy consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

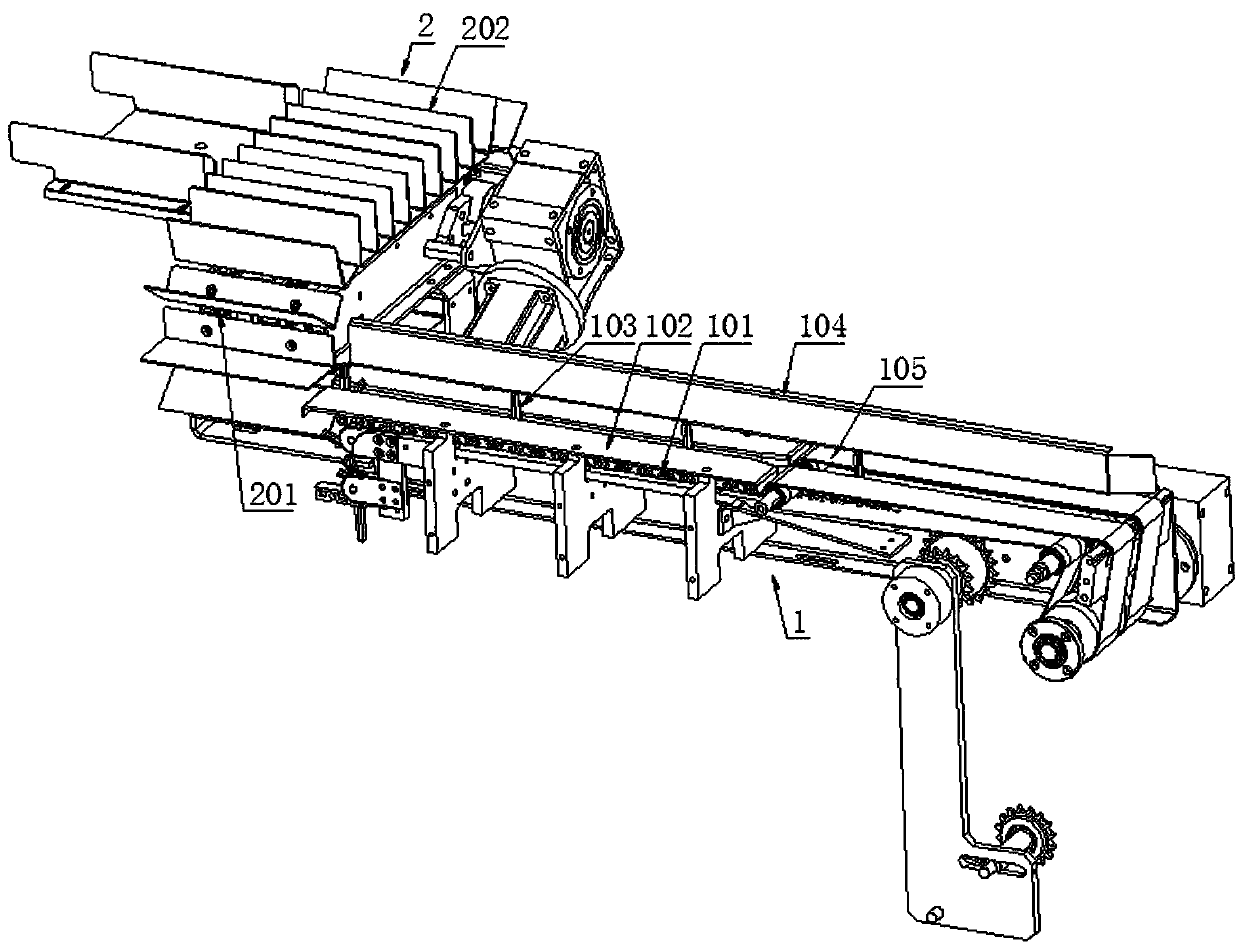

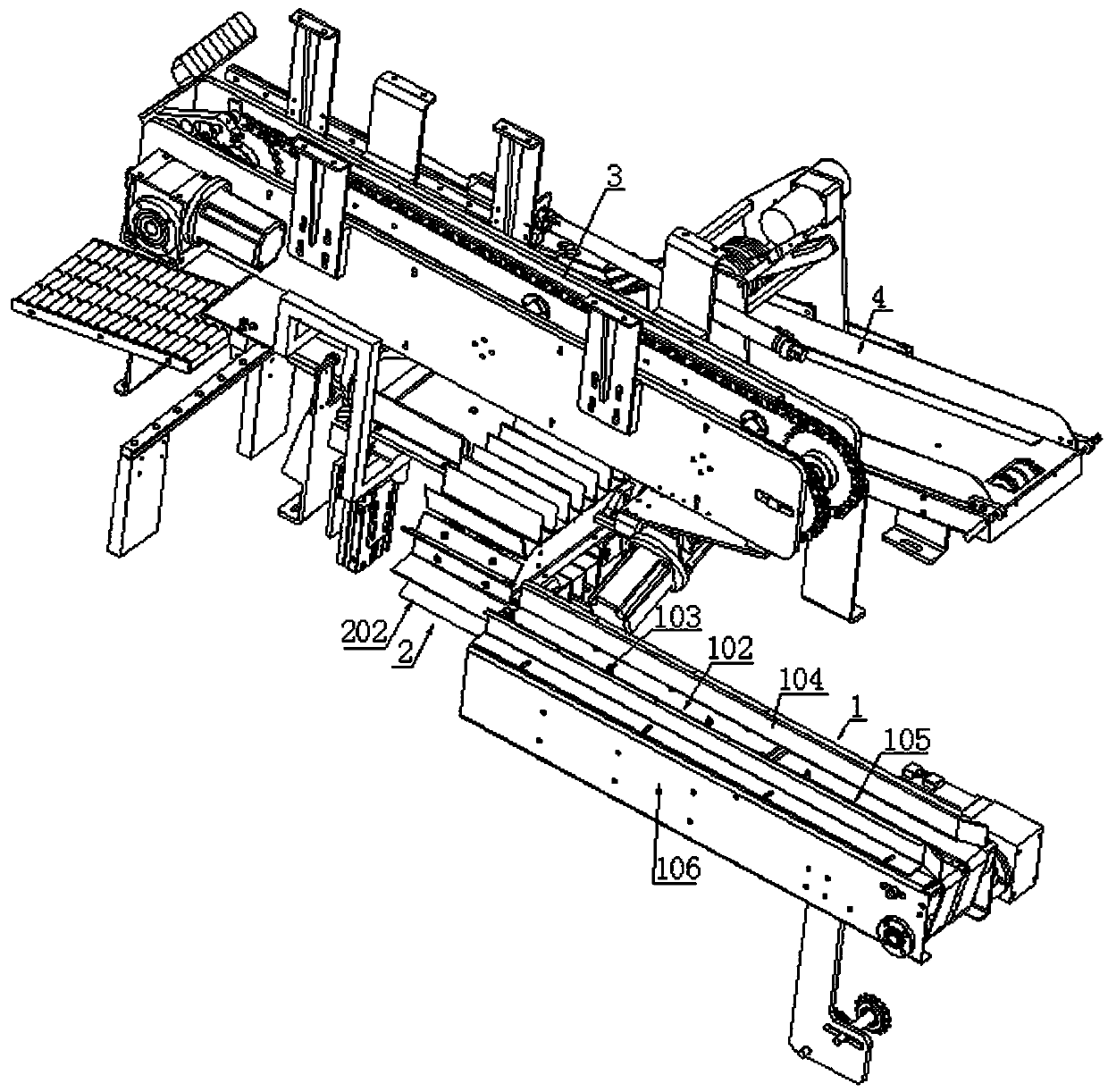

[0053] This embodiment provides a bag stretching method for a packaging machine, which is characterized in that it includes the steps of bag receiving, translation, bag opening, bag stretching and translation reset,

[0054] The bag receiving means that the bag receiving plate 501 is connected to the prefabricated bag at the bag receiving station 505, and is fixed by the adsorption hole 503 on the bag receiving plate 501 corresponding to the opening of the prefabricated bag;

[0055] The translation means that the bag receiving plate 501 is translated from the bag receiving station 505 to the bag opening and opening station 506 under the drive of the translation mechanism. Translate from bag receiving station 505 to bag opening station 506;

[0056] The bag opening means that the suction cup 6 absorbs the upper side of the bag mouth at the bag opening station 506, and cooperates with the adsorption hole 503 on the lower side of the bag mouth to open the bag mouth;

[0057] Th...

Embodiment 2

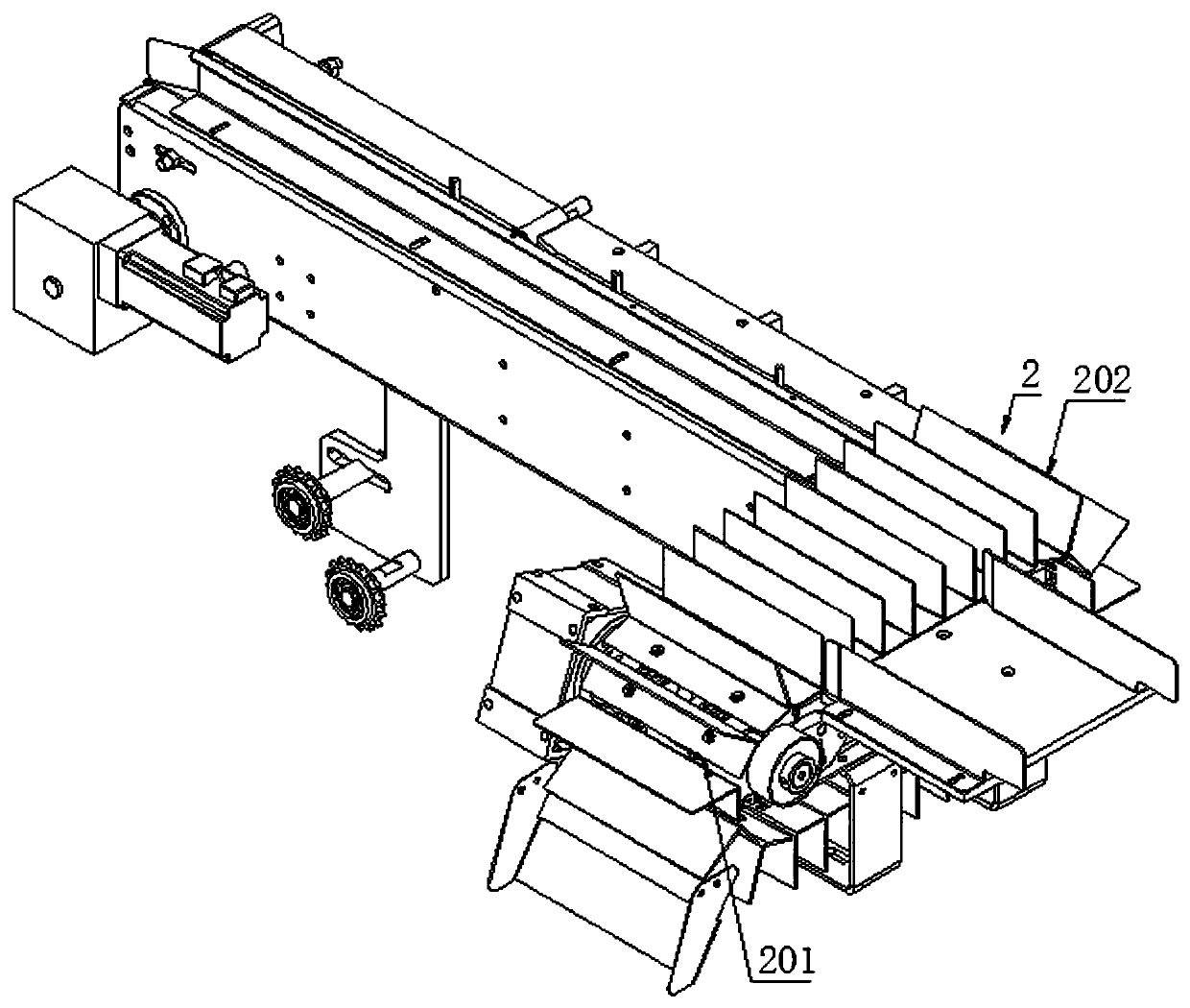

[0061] This embodiment provides a bag receiving and conveying mechanism 5 of a packaging machine, through the function of the bag receiving and conveying mechanism 5, the bag receiving and conveying action of prefabricated bags is realized, and the specific structure is as follows:

[0062] The bag receiving conveying mechanism 5 includes a bag receiving plate 501 and a translation mechanism that enables the bag receiving plate 501 to reciprocate between the bag receiving station 505 and the bag opening station. There are adsorption holes 503;

[0063] There is only one position on the side of the bag receiving plate 501 corresponding to the opening of the prefabricated bag with an adsorption hole 503 .

[0064] The adsorption hole 503 can only absorb the lower side of the mouth of the prefabricated bag.

[0065] The translation mechanism includes a power source and a guide 502 , the pocket plate 501 is movably mounted on the guide 502 , and the power source drives the pocket...

Embodiment 3

[0068] This embodiment provides a bag receiving and conveying mechanism 5 of a packaging machine, through the function of the bag receiving and conveying mechanism 5, the bag receiving and conveying action of prefabricated bags is realized, and the specific structure is as follows:

[0069] The bag receiving conveying mechanism 5 includes a bag receiving plate 501 and a translation mechanism that enables the bag receiving plate 501 to reciprocate between the bag receiving station 505 and the bag opening station. There are adsorption holes 503;

[0070] The translation mechanism includes a power source and a guide 502 , the pocket plate 501 is movably mounted on the guide 502 , and the power source drives the pocket plate 501 to move on the guide 502 .

[0071] The upper surface of the guide 502 is provided with a bar-shaped groove, and the bar-shaped groove is arranged along the length direction of the guide 502. The lower surface of the pocket plate 501 is provided with a bar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com